Feeling lost in a sea of interview questions? Landed that dream interview for Cutting Inspector but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Cutting Inspector interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

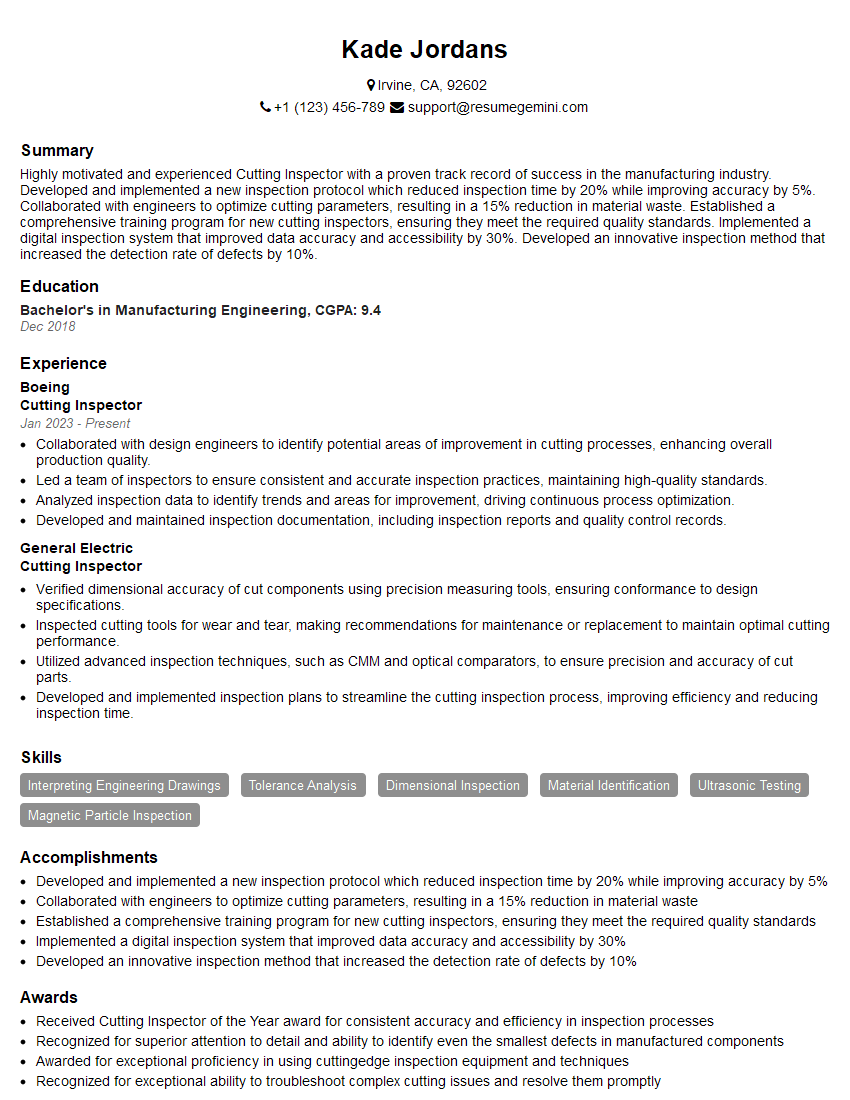

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cutting Inspector

1. Explain the different types of cutting defects?

- Burrs: Raised edges left behind when material is cut.

- Chips: Pieces of material removed during cutting.

- Cracks: Breaks or splits in the material.

- Flaws: Imperfections in the material that can affect the cut quality.

- Gouges: Grooves or scratches in the material caused by cutting.

2. What are the causes of these defects and how can they be prevented?

Burrs

- Blunt cutting tools.

- Incorrect cutting speeds.

- Dull cutting tools.

Chips

- Improperly sharpened cutting tools.

- Excessive cutting speeds.

- Insufficient coolant.

3. Describe the process of cutting tool inspection?

A cutting tool inspection involves checking the tool for any signs of wear, damage, or defects. This is important to ensure that the tool is functioning properly and will produce quality cuts. The inspection process typically involves visual inspection, dimensional measurement, and performance testing. Visual inspection involves looking for any obvious signs of damage, such as cracks, chips, or burrs. Dimensional measurement involves checking the tool’s dimensions to ensure that they are within tolerance. Performance testing involves testing the tool’s cutting performance to ensure that it is meeting the required standards.

4. What are the different methods of cutting tool measurement?

- Optical comparators.

- Coordinate measuring machines.

- Toolmakers’ microscopes.

- Dial indicators.

- Micrometers.

5. What are the different types of cutting tools used?

- Turning tools.

- Milling tools.

- Drilling tools.

- Boring tools.

- Reaming tools.

6. What are the factors that affect the selection of cutting tool materials?

- The type of material being cut.

- The cutting speed.

- The feed rate.

- The depth of cut.

- The coolant used.

7. What is the role of cutting fluids in the cutting process?

- Cooling the cutting tool and workpiece.

- Lubricating the cutting tool and workpiece.

- Washing away chips and debris.

- Protecting the cutting tool and workpiece from corrosion.

8. What are the different types of cutting fluids?

- Oils.

- Water-based fluids.

- Synthetic fluids.

- Gases.

9. What are the advantages and disadvantages of using cutting fluids?

Advantages

- Improved cutting tool life.

- Improved workpiece surface finish.

- Reduced cutting forces.

- Reduced cutting temperatures.

- Improved chip control.

Disadvantages

- Cost.

- Environmental concerns.

- Safety concerns.

10. What are the different types of cutting machines?

- Lathes.

- Milling machines.

- Drilling machines.

- Boring machines.

- Reaming machines.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cutting Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cutting Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cutting Inspectors are responsible for ensuring that cutting operations are performed according to specifications. They inspect raw materials, finished products, and cutting tools to ensure that they meet quality standards. Cutting Inspectors may also be responsible for training new employees, maintaining inspection equipment, and developing inspection procedures.

1. Inspect raw materials

Cutting Inspectors must inspect raw materials to ensure that they meet the correct specifications. This may involve checking the dimensions, thickness, and surface finish of the materials. Cutting Inspectors may also be responsible for checking the materials for defects, such as cracks, scratches, or dents.

2. Inspect finished products

Cutting Inspectors must inspect finished products to ensure that they meet the correct specifications. This may involve checking the dimensions, thickness, and surface finish of the products. Cutting Inspectors may also be responsible for checking the products for defects, such as cracks, scratches, or dents.

3. Inspect cutting tools

Cutting Inspectors must inspect cutting tools to ensure that they are sharp and in good condition. This may involve checking the cutting edges, the angles of the cutting tools, and the overall condition of the tools. Cutting Inspectors may also be responsible for sharpening cutting tools and replacing worn-out tools.

4. Train new employees

Cutting Inspectors may be responsible for training new employees on how to perform cutting operations. This may involve teaching new employees how to use cutting tools, how to inspect materials and products, and how to follow safety procedures.

Interview Tips

Interviews for cutting inspector roles can be competitive. Here are a few tips to help you prepare for your interview:

1. Research the company and the role

Before your interview, be sure to research the company and the specific cutting inspector role you are applying for. This will help you understand the company’s culture, values, and what they are looking for in a cutting inspector. Be prepared to talk about why the specific company is a good fit for you and why you are the best candidate for the role.

2. Be prepared to talk about your experience

In your interview, be prepared to talk about your experience as a cutting inspector. This may include discussing your experience inspecting raw materials, finished products, and cutting tools. Be sure to highlight your skills and experience in the area.

3. Be prepared to answer questions about safety

Interviewers will want to know that you are committed to safety. Be prepared to answer questions about your safety record and your experience following safety procedures.

4. Be professional and prepared

As with any interview, it is important to be professional and prepared. Dress appropriately, arrive on time, and be prepared to answer questions about your experience and qualifications.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Cutting Inspector, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Cutting Inspector positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.