Are you gearing up for an interview for a Cylinder Inspector position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Cylinder Inspector and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

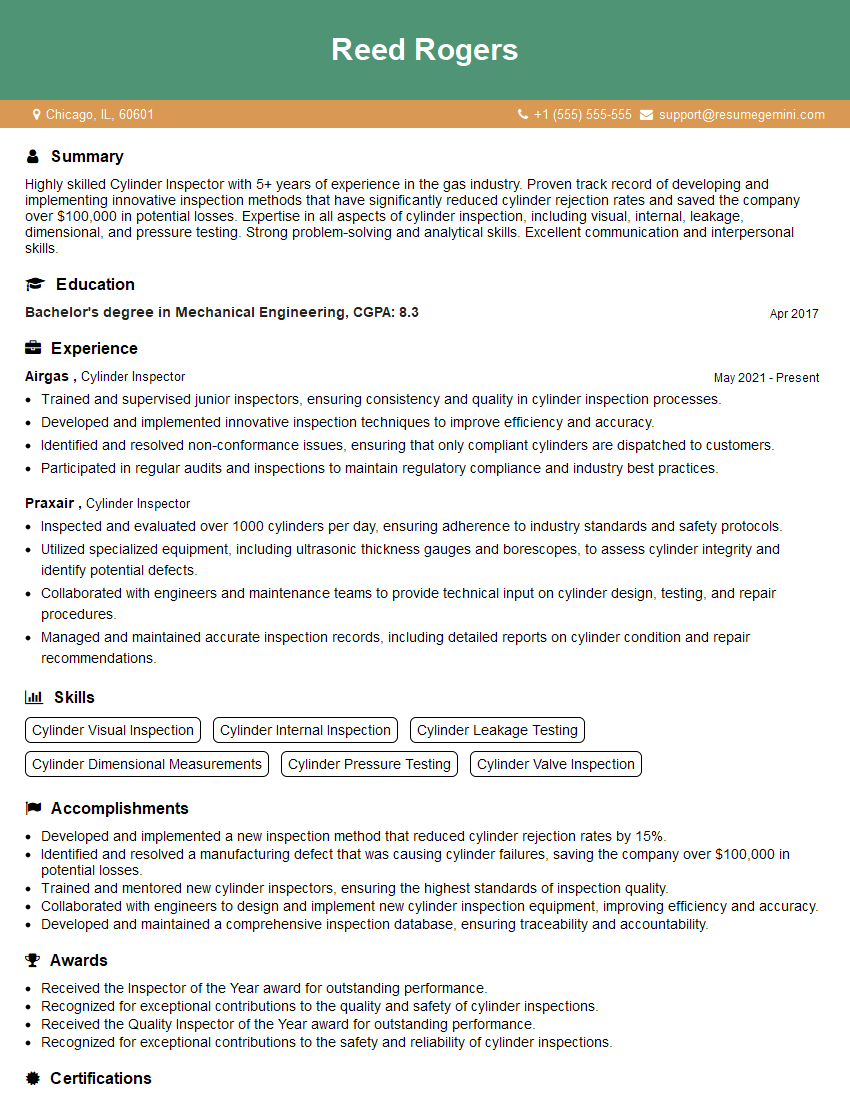

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cylinder Inspector

1. What are the key dimensions of a cylinder that you inspect?

The key dimensions of a cylinder that I inspect include:

- Outside diameter (OD): This is the diameter of the cylinder’s outer surface.

- Inside diameter (ID): This is the diameter of the cylinder’s inner surface.

- Height: This is the distance between the cylinder’s top and bottom surfaces.

- Wall thickness: This is the thickness of the cylinder’s wall.

- Roundness: This is the extent to which the cylinder’s cross-section is circular.

- Straightness: This is the extent to which the cylinder’s walls are parallel to each other.

- Surface finish: This is the smoothness of the cylinder’s surfaces.

2. What types of defects can you identify in a cylinder?

Defects in the cylinder’s material

- Cracks

- Voids

- Inclusions

Defects in the cylinder’s shape

- Dents

- Bulges

- Taper

- Out-of-roundness

Defects in the cylinder’s surface finish

- Scratches

- Gouges

- Pits

- Corrosion

3. What are the different inspection methods that you use?

The different inspection methods that I use include:

- Visual inspection: This involves looking at the cylinder’s surface for any visible defects.

- Dimensional inspection: This involves using measuring tools to check the cylinder’s dimensions.

- Non-destructive testing (NDT): This involves using non-destructive methods to check the cylinder’s internal structure for any defects.

- Leak testing: This involves checking the cylinder for any leaks.

4. What are the acceptance criteria for a cylinder?

The acceptance criteria for a cylinder are based on the customer’s specifications. However, some general acceptance criteria include:

- The cylinder must be free of any cracks, voids, or other defects.

- The cylinder must meet the specified dimensions.

- The cylinder must have a surface finish that meets the specified requirements.

- The cylinder must be leak-tight.

5. How do you ensure the accuracy of your inspections?

I ensure the accuracy of my inspections by:

- Using calibrated measuring tools: I use measuring tools that have been calibrated to ensure that they are accurate.

- Following established procedures: I follow established procedures for each inspection method that I use.

- Verifying my results: I verify my results by having another inspector check my work.

6. What are the most common problems that you encounter in your work?

The most common problems that I encounter in my work include:

- Defective cylinders: I often encounter cylinders that have defects, such as cracks, voids, or other defects.

- Inaccurate measurements: I sometimes encounter cylinders that have been incorrectly measured.

- Customer complaints: I occasionally receive complaints from customers about the quality of my inspections.

7. How do you resolve these problems?

I resolve these problems by:

- Inspecting the cylinders carefully: I carefully inspect the cylinders to identify any defects.

- Re-measuring the cylinders: I re-measure the cylinders to ensure that the measurements are accurate.

- Working with the customer: I work with the customer to resolve any complaints.

8. What are your strengths as a Cylinder Inspector?

My strengths as a Cylinder Inspector include:

- Attention to detail: I am very attentive to detail and I am able to identify even the smallest defects.

- Accuracy: I am very accurate in my work and I take pride in providing high-quality inspections.

- Customer service: I am committed to providing excellent customer service and I am always willing to go the extra mile to satisfy my customers.

9. What are your weaknesses as a Cylinder Inspector?

My weaknesses as a Cylinder Inspector include:

- Speed: I am not the fastest inspector, but I am very thorough and I never compromise on quality.

- Experience: I am a relatively new inspector, but I am eager to learn and I am confident that I will quickly develop the skills and experience necessary to be a top-notch inspector.

10. Why are you interested in this job?

I am interested in this job because I am passionate about quality control and I believe that I have the skills and experience necessary to be a successful Cylinder Inspector. I am also excited about the opportunity to work with a leading company in the industry and I am confident that I can make a significant contribution to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cylinder Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cylinder Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cylinder Inspectors play a crucial role in maintaining the safety and quality of gas cylinders, ensuring compliance with industry standards and regulations. Their key job responsibilities include:

1. Cylinder Inspection and Testing

Thoroughly inspecting cylinders visually and using specialized equipment to identify any defects, corrosion, or damage that could compromise the cylinder’s integrity.

- Conducting hydrostatic testing, volumetric testing, and leak testing to assess cylinder strength, volume capacity, and gas tightness.

- Verifying cylinder markings, including identification numbers, capacity, and test dates, to ensure compliance with specifications.

2. Documentation and Reporting

Maintaining accurate records of all inspections and tests performed, including detailed descriptions of any defects or non-conformities detected.

- Preparing and submitting inspection reports to management, customers, or regulatory agencies as required.

- Collaborating with maintenance or repair teams to resolve any detected issues and ensure the safe return of cylinders to service.

3. Quality Control and Compliance

Monitoring and implementing quality control procedures to ensure the consistent accuracy and reliability of cylinder inspections.

- Adhering to industry standards, regulations, and company policies related to cylinder inspection and testing.

- Participating in training and certification programs to maintain up-to-date knowledge and skills.

4. Safety and Customer Service

Prioritizing safety during all inspection and testing procedures, ensuring the wellbeing of colleagues and customers.

- Providing excellent customer service by promptly addressing inquiries, resolving issues, and maintaining positive relationships.

- Working effectively as part of a team and collaborating with other departments, including sales, operations, and maintenance.

Interview Tips

To prepare for an interview for a Cylinder Inspector position, it is essential to demonstrate a thorough understanding of the role and highlight your relevant skills and experience.

1. Research the Industry and Company

Familiarize yourself with the industry standards, regulations, and best practices related to cylinder inspection. Research the company’s reputation, values, and safety culture.

2. Highlight Your Technical Skills

Emphasize your proficiency in cylinder inspection techniques, testing equipment, and quality control procedures. Provide examples of how you have successfully identified and resolved cylinder defects.

3. Showcase Your Safety Mindset

Demonstrate your commitment to safety by discussing your understanding of industry regulations, your adherence to safe work practices, and your ability to mitigate potential hazards.

4. Prepare for Common Interview Questions

Anticipate questions about your experience in cylinder inspection, your knowledge of industry standards, and your ability to work independently and as part of a team.

5. Prepare Questions for the Interviewer

Prepare thoughtful questions to ask the interviewer about the company’s safety culture, training opportunities, and career advancement prospects. This shows your interest and engagement.

6. Practice Your Communication Skills

Practice your communication skills to clearly and confidently convey your technical knowledge and experience. Be prepared to explain complex concepts in a straightforward manner.

7. Dress Professionally and Arrive on Time

Dress professionally and arrive on time for your interview. This conveys respect for the interviewer and the company and creates a positive first impression.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cylinder Inspector interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.