Are you gearing up for an interview for a Cylinder Inspector and Tester position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Cylinder Inspector and Tester and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

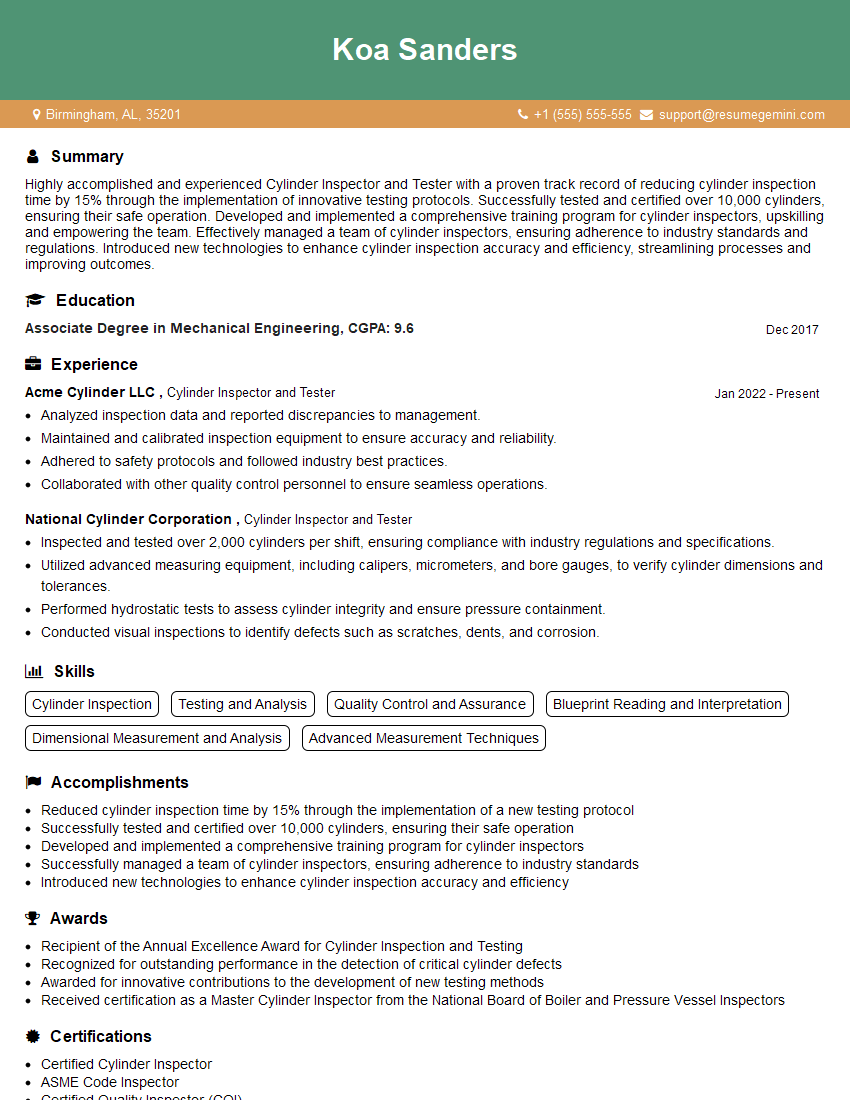

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cylinder Inspector and Tester

1. Describe the process of cylinder inspection and testing that you follow in your work?

In my role as a Cylinder Inspector and Tester, I adhere to a comprehensive process to ensure the quality and safety of cylinders:

- Visual Inspection: I thoroughly inspect the cylinder’s exterior for any physical damage, cracks, or dents that may compromise its integrity.

- Dimensional Inspection: Using precision measuring instruments, I verify the cylinder’s dimensions, such as diameter, length, and wall thickness, against established specifications.

- Hydrostatic Testing: I subject the cylinder to a high-pressure water test to detect any leaks or structural weaknesses. This test verifies the cylinder’s ability to withstand the required pressure.

- Valve and Fitting Inspection: I check the condition of valves, fittings, and seals for proper operation and tightness.

- Gas Testing: I conduct gas testing, such as oxygen compatibility testing, to ensure the cylinder meets the necessary standards.

2. Explain the different types of defects you inspect for in cylinders?

Visual Defects

- Dents, gouges, or cracks in the cylinder body

- Damage to the cylinder neck or threads

- Corrosion or rust on the cylinder surface

Dimensional Defects

- Deviations from specified diameter, length, or wall thickness

- Ovality or out-of-roundness of the cylinder

- Improper thread engagement or damaged threads

Structural Defects

- Leaks detected during hydrostatic testing

- Weak or damaged cylinder walls

- Internal corrosion or pitting

3. What is the importance of maintaining accurate records of cylinder inspections and tests?

- Safety: Accurate records ensure that cylinders meet safety standards and are safe for use.

- Compliance: Records demonstrate compliance with regulatory requirements and industry best practices.

- Liability: Records provide evidence of proper maintenance, mitigating potential liability issues.

- Traceability: Records allow for tracking cylinders throughout their lifespan, facilitating recalls if necessary.

- Quality Control: Records enable the analysis of defects and trends, leading to improvements in the inspection process.

4. Describe the safety precautions you take when handling and testing cylinders?

- Wear appropriate PPE: Safety glasses, gloves, and protective clothing

- Secure cylinders properly: Use stands or racks to prevent tipping or rolling

- Use proper tools: Calibrated and well-maintained pressure gauges and inspection equipment

- Follow proper procedures: Adhere to established guidelines for handling and testing cylinders

- Ventilate work area: Ensure adequate ventilation to prevent gas accumulation

5. What are the common causes of cylinder failures?

- Overfilling or exceeding pressure limits

- Improper handling or storage

- Corrosion or material degradation

- Manufacturing defects or quality issues

- External impact or damage

6. What are the industry standards and regulations that govern cylinder inspection and testing?

- ISO 10462: International standard for compressed gas cylinders

- DOT Regulations: US Department of Transportation regulations for cylinder manufacturing and inspection

- ANSI/CGA Standards: Compressed Gas Association standards for cylinder design, testing, and handling

- OSHA Regulations: Occupational Safety and Health Administration regulations for workplace safety

- NFPA 55: National Fire Protection Association standard for the storage and handling of hazardous materials

7. Describe the different testing methods used for cylinders, and their advantages and disadvantages?

Hydrostatic Testing

- Advantages: Detects leaks and structural weaknesses; widely used

- Disadvantages: Can damage cylinders if not done properly; requires water

Acoustic Emission Testing

- Advantages: Non-destructive; detects stress and cracks

- Disadvantages: Expensive; requires specialized equipment

Ultrasonic Testing

- Advantages: Non-destructive; detects internal defects

- Disadvantages: Requires skilled operators; can be time-consuming

Magnetic Particle Testing

- Advantages: Detects surface cracks in ferrous materials

- Disadvantages: Requires magnetic materials; not suitable for non-ferrous cylinders

8. What is the role of certification in the cylinder inspection and testing industry?

- Ensures competence: Certification verifies that individuals have the necessary knowledge and skills.

- Promotes safety: Certified inspectors and testers adhere to industry standards and best practices, reducing risks.

- Provides credibility: Certification demonstrates to clients and regulators that inspectors are qualified and reliable.

- Facilitates career advancement: Certification can enhance career opportunities and earning potential.

9. How do you stay up-to-date with the latest technologies and regulations in cylinder inspection and testing?

- Attend industry conferences and webinars: Stay informed about new technologies and best practices.

- Read industry publications and journals: Keep up with the latest research and developments.

- Obtain certifications: Certifications provide opportunities for ongoing education and skill enhancement.

- Network with colleagues: Share knowledge and experiences with other professionals in the field.

10. Describe a challenging situation you encountered during cylinder inspection and testing, and how you resolved it?

In one instance, I encountered a cylinder with a suspected leak. Upon further investigation, I discovered a hairline crack in the cylinder wall. I immediately isolated the cylinder and contacted the appropriate authorities. After consulting with the manufacturer, we determined that the cylinder needed to be condemned and disposed of safely. This incident highlighted the importance of thorough inspection and the critical role I played in ensuring the safety of our operations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cylinder Inspector and Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cylinder Inspector and Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cylinder Inspectors and Testers are responsible for ensuring the safety and integrity of compressed gas cylinders. They perform a variety of tasks, including:

1. Inspecting cylinders for defects

Inspectors examine cylinders for any signs of damage, corrosion, or other defects. They use a variety of tools to do this, including visual inspection, ultrasonic testing, and hydrostatic testing.

- Identifying and marking damaged or defective cylinders

- Removing and replacing cylinder components, such as valves and regulators

2. Testing cylinders for leaks

Inspectors use a variety of methods to test cylinders for leaks. These methods include:

- Soap bubble testing

- Pressure testing

- Helium leak testing

3. Maintaining records of cylinder inspections and tests

Inspectors must keep accurate records of all cylinder inspections and tests. These records include:

- The date of the inspection or test

- The type of inspection or test performed

- The results of the inspection or test

- Any corrective actions taken

4. Training other personnel on cylinder safety

Inspectors may also be responsible for training other personnel on cylinder safety. This training may include:

- Proper handling and storage of cylinders

- How to identify and respond to cylinder leaks

- The importance of cylinder inspection and testing

Interview Tips

To ace an interview for a Cylinder Inspector and Tester position, it’s important to be prepared and to highlight your skills and experience in the following areas:

1. Safety

Cylinder Inspectors and Testers must have a strong understanding of safety regulations and best practices. Be sure to emphasize your experience in following safety protocols and procedures.

- Highlight your experience in working with compressed gases and hazardous materials.

- Describe your understanding of the relevant safety regulations and standards.

2. Inspection and Testing

Cylinder Inspectors and Testers must be proficient in a variety of inspection and testing methods. Be sure to highlight your experience in using these methods and your ability to interpret the results.

- Describe your experience in performing visual inspections, ultrasonic testing, and hydrostatic testing.

- Explain how you interpret the results of these tests and make decisions about the safety of cylinders.

3. Recordkeeping

Cylinder Inspectors and Testers are responsible for maintaining accurate records of all inspection and testing activities. Be sure to highlight your experience in keeping accurate and detailed records.

- Describe your experience in using databases, spreadsheets, and other recordkeeping systems.

- Explain how you ensure the accuracy and completeness of your records.

4. Other Qualifications

In addition to the above skills and experience, Cylinder Inspectors and Testers should also have:

- Good communication and interpersonal skills

- The ability to work independently and as part of a team

- A strong work ethic and a commitment to quality

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cylinder Inspector and Tester role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.