Feeling lost in a sea of interview questions? Landed that dream interview for Diesel Engine Tester but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Diesel Engine Tester interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

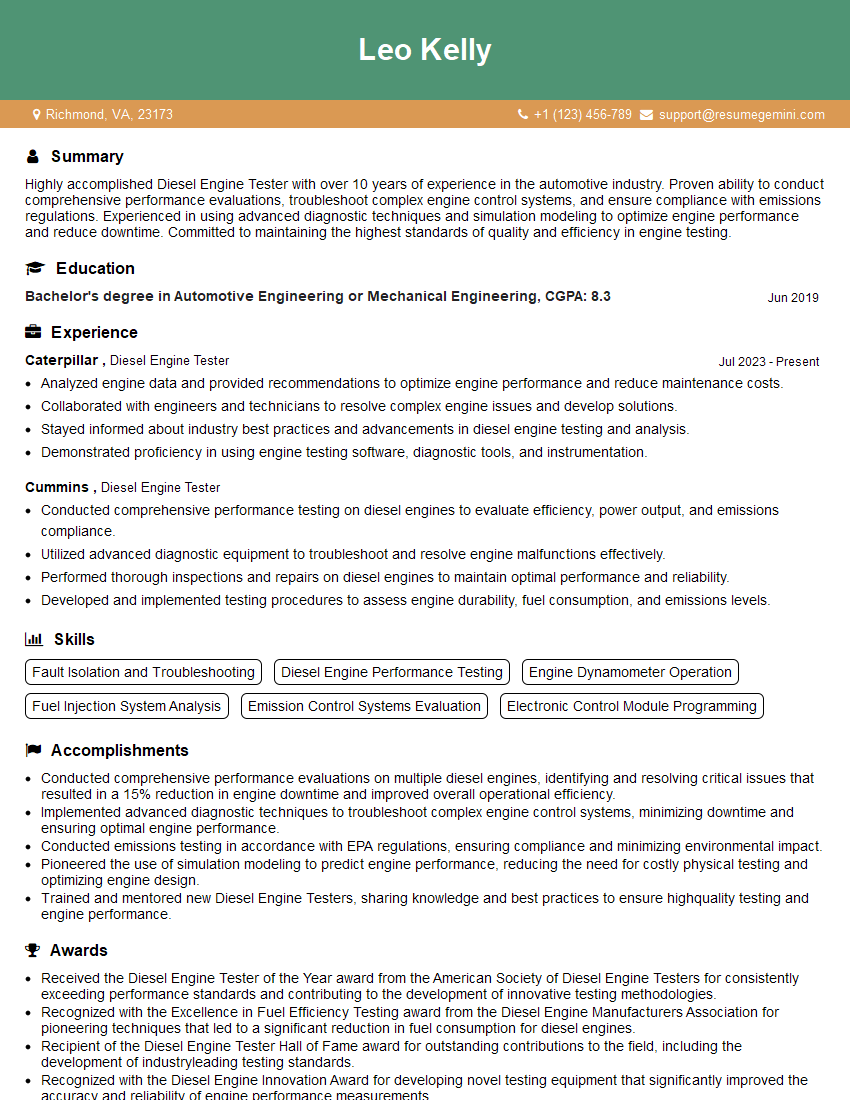

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Diesel Engine Tester

1. Explain the process of performing a compression test on a diesel engine?

The process of performing a compression test on a diesel engine involves the following steps:

- Remove the glow plugs or injectors from the engine.

- Insert the compression tester into the cylinder.

- Crank the engine over until the compression tester reaches its maximum reading.

- Record the compression reading.

- Repeat the process for each cylinder.

2. What are the specifications for cylinder compression on a diesel engine?

Compression ratio indicates an engine’s ability to compress air

specifications for cylinder compression on a diesel engine:

- Compression ratio typically ranges from 14:1 to 22:1.

- The minimum acceptable compression ratio is typically 12:1.

- A difference of more than 10% between cylinders indicates a potential problem.

3. What are the common causes of low compression in a diesel engine?

Low compression in a diesel engine can be caused by a number of factors, including:

- Worn or damaged piston rings.

- Worn or damaged cylinder liners.

- Leaking valves.

- Blown head gasket.

4. How do you troubleshoot a diesel engine that is not starting?

Troubleshooting a diesel engine that is not starting involves a systematic approach to identify the root cause of the problem.

- Checking the fuel supply.

- Checking the electrical system.

- Checking the compression.

- Checking the timing.

5. What are the different types of fuel injection systems used in diesel engines?

The different types of fuel injection systems used in diesel engines include:

- Mechanical fuel injection.

- Electronic fuel injection.

- Common rail fuel injection.

6. What are the advantages and disadvantages of mechanical fuel injection?

Advantages of mechanical fuel injection include:

- Simple and reliable.

- Relatively low cost.

Disadvantages of mechanical fuel injection include:

- Not as precise as electronic fuel injection.

- Can be more difficult to troubleshoot.

7. What are the advantages and disadvantages of electronic fuel injection?

Advantages of electronic fuel injection include:

- More precise than mechanical fuel injection.

- Allows for more precise control of the fuel injection process.

- Easier to troubleshoot than mechanical fuel injection.

Disadvantages of electronic fuel injection include:

- More expensive than mechanical fuel injection.

- Can be more complex to repair.

8. What are the advantages and disadvantages of common rail fuel injection?

Advantages of common rail fuel injection include:

- Very precise.

- Allows for very high injection pressures.

- Can be used to achieve very high fuel efficiency and power output.

Disadvantages of common rail fuel injection include:

- Very expensive.

- Can be complex to repair.

9. What are the different types of emission control systems used in diesel engines?

The different types of emission control systems used in diesel engines include:

- Exhaust gas recirculation (EGR).

- Diesel particulate filter (DPF).

- Selective catalytic reduction (SCR).

10. What is the purpose of an exhaust gas recirculation (EGR) system?

The purpose of an exhaust gas recirculation (EGR) system is to reduce the formation of nitrogen oxides (NOx) emissions.

- NOx emissions are harmful to the environment and can contribute to smog formation.

- EGR systems work by recirculating a portion of the exhaust gas back into the engine’s intake manifold.

- This helps to reduce the combustion temperature and reduce the formation of NOx emissions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Diesel Engine Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Diesel Engine Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Diesel Engine Testers are responsible for ensuring that diesel engines meet performance and safety standards. They perform a variety of tests on engines, including:

1. Engine Performance Tests

These tests measure the power, torque, fuel efficiency, and emissions of an engine. They are used to ensure that the engine is meeting its design specifications.

- Conducting performance tests on diesel engines to evaluate their power, torque, fuel efficiency, and emissions.

- Analyzing test data to identify and diagnose any issues or deviations from specifications.

2. Endurance Tests

These tests are designed to simulate real-world operating conditions and assess the durability of an engine. They can last for hundreds or even thousands of hours.

- Performing endurance tests on diesel engines to assess their reliability and durability under various operating conditions.

- Monitoring engine parameters such as temperature, pressure, and vibration during testing.

3. Emissions Tests

These tests measure the levels of pollutants emitted by an engine. They are used to ensure that the engine meets environmental regulations.

- Conducting emissions tests on diesel engines to measure their emissions of pollutants such as nitrogen oxides, particulate matter, and hydrocarbons.

- Ensuring that diesel engines meet applicable emissions standards and regulations.

4. Troubleshooting and Repair

Diesel Engine Testers may also be responsible for troubleshooting and repairing engines. They use their knowledge of engine systems to identify and fix problems.

- Troubleshooting and repairing diesel engines to resolve any issues or malfunctions.

- Replacing or repairing damaged components and conducting necessary adjustments.

Interview Tips

Preparing for an interview for a Diesel Engine Tester position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the Company and the Position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and what they are looking for in a Diesel Engine Tester.

- Visit the company’s website and social media pages.

- Read articles and news about the company.

- Talk to people in your network who work for the company.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Why do you want to work for our company?” and “What are your strengths and weaknesses?” Practice your answers to these questions so that you can deliver them confidently and concisely.

- Use the STAR method to answer behavioral questions.

- Focus on your relevant skills and experience.

- Be enthusiastic and positive.

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience working with diesel engines. Be prepared to talk about your specific responsibilities, your accomplishments, and your knowledge of diesel engine systems.

- Highlight your experience in conducting engine performance, endurance, emissions, and troubleshooting tests.

- Quantify your accomplishments with specific examples.

- Demonstrate your understanding of diesel engine design, operation, and maintenance.

4. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the company, the position, and the next steps in the hiring process. This will show that you are engaged in the conversation and that you are interested in the opportunity.

- Ask about the company’s culture and values.

- Ask about the specific responsibilities of the position.

- Ask about the next steps in the hiring process.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Diesel Engine Tester role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.