Are you gearing up for a career in Drilling Inspector? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Drilling Inspector and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

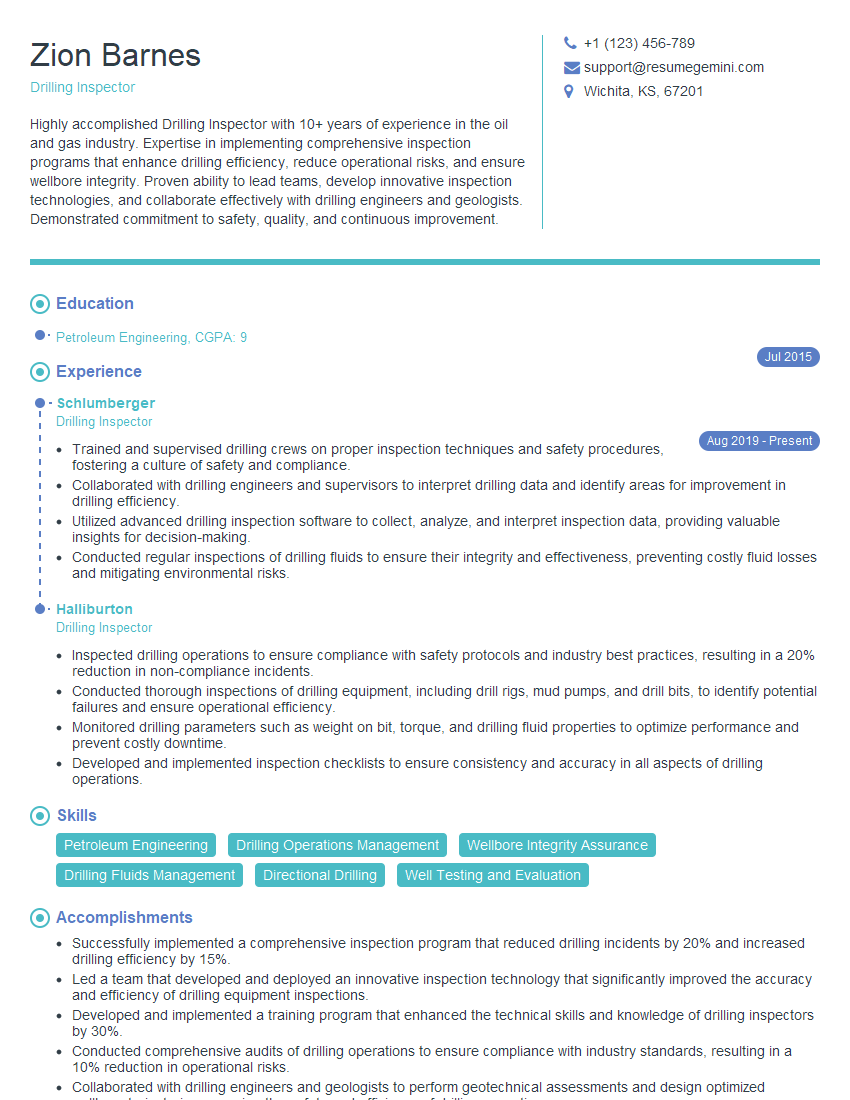

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drilling Inspector

1. What are the key responsibilities of a Drilling Inspector?

The primary responsibilities of a Drilling Inspector include:

- Ensuring compliance with drilling plans, procedures, and regulations.

- Monitoring drilling operations and equipment to identify potential hazards and mitigate risks.

- Inspecting and maintaining drilling equipment to ensure proper operation and safety.

- Recording and reporting drilling data, including logs, reports, and inspections.

- Collaborating with drilling engineers, geologists, and other personnel to optimize drilling operations.

2. Describe the different types of drilling equipment you have experience with.

Drilling Rigs

- Land rigs

- Offshore rigs

- Mobile rigs

Drilling Tools

- Drill bits

- Drill collars

- Drill pipes

- Drilling fluids

3. What are the most common drilling hazards and how do you mitigate them?

- Blowouts: Controlled by maintaining well control through proper drilling practices and equipment.

- Fires: Mitigated by following strict safety protocols, including proper handling of flammable materials and ignition sources.

- Wellbore instability: Avoided through proper hole cleaning and mud management techniques.

- Environmental pollution: Minimized through spill prevention and containment measures.

- Equipment failure: Prevented through regular inspections, maintenance, and redundancy systems.

4. How do you ensure well control during drilling operations?

- Maintaining proper mud weight and density: Prevents wellbore fluids from entering the wellbore.

- Installing blowout preventers (BOPs): Mechanical devices that seal the wellbore in case of a blowout.

- Managing drilling parameters: Controlling rate of penetration, drilling torque, and mud flow to prevent formation damage and pressure imbalances.

- Conducting pressure tests: Verifying integrity of BOPs and wellbore equipment.

- Training and certification: Ensuring personnel are qualified and competent in well control procedures.

5. What are the key factors to consider when selecting drilling fluids?

- Formation characteristics: Compatibility with rock types and pore fluids.

- Drilling depth and conditions: Pressure, temperature, and corrosive environment.

- Drilling objectives: Hole cleaning, wellbore stability, and formation evaluation.

- Environmental regulations: Compliance with environmental standards.

- Cost and availability: Budget and logistical considerations.

6. How do you interpret drilling logs and reports?

- Lithologic logs: Identify and characterize rock formations.

- Drilling parameter logs: Analyze drilling performance and identify potential problems.

- Wellbore surveys: Determine the trajectory and inclination of the wellbore.

- Mud logs: Monitor drilling fluid properties and formation cuttings.

- Geophysical logs: Evaluate formation properties such as porosity, permeability, and fluid content.

7. What are the different methods of directional drilling and when are they used?

-

Types of Directional Drilling:

- Rotary steerable systems: Controlled deflection of the drill bit.

- Motor assemblies: Bent housing deflects the drill bit.

- Whipstocks and sidetracks: Kicking off a new wellbore from an existing one. Applications:

- Drilling under obstacles

- Reaching targets with complex trajectories

- Improving wellbore stability

- Optimizing production from reservoirs

8. What are the key components of a drilling program?

- Drilling objectives: Clearly defined goals and expected outcomes.

- Geological and geophysical data: Understanding of subsurface conditions.

- Rig selection: Matching rig capabilities to well requirements.

- Drilling method: Rotary, percussion, or directional drilling.

- Drilling fluid selection: Optimizing properties for drilling performance.

- Casing and cementing plan: Ensuring wellbore stability and preventing fluid migration.

- Environmental impact assessment: Mitigating potential risks.

- Drilling schedule: Timelines and milestones for operations.

9. How do you manage drilling waste and ensure environmental compliance?

- Waste characterization: Identifying hazardous and non-hazardous waste.

- Waste management plan: Outlining disposal, recycling, and treatment methods.

- Spill prevention and response: Implementing protocols to minimize environmental impact.

- Monitoring and reporting: Tracking waste generation and disposal.

- Regulatory compliance: Adhering to environmental standards and regulations.

10. How do you work effectively with a drilling team and other stakeholders?

- Communication: Exchanging information clearly and effectively.

- Collaboration: Working together to achieve common goals.

- Leadership: Providing guidance and direction to the team.

- Teamwork: Cooperating and supporting each other.

- Problem-solving: Identifying and resolving issues as a team.

- Stakeholder management: Building relationships and understanding their needs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drilling Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drilling Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Drilling Inspector is responsible for monitoring and ensuring the safety and efficiency of drilling operations. They work closely with drilling crews to ensure that all drilling activities are carried out according to established standards and regulations and that all safety protocols are strictly followed.

1. Monitoring Drilling Operations

Drilling Inspectors are responsible for overseeing all aspects of drilling operations, including:

- Observing and recording drilling parameters such as drilling fluid properties, bit weight, and torque.

- Monitoring the performance of drilling equipment and machinery.

- Ensuring that all drilling operations are carried out according to established procedures and best practices.

2. Ensuring Safety and Compliance

Drilling Inspectors are responsible for ensuring the safety of drilling operations and the compliance with all applicable regulations. Their duties include:

- Conducting regular safety inspections to identify and eliminate potential hazards

- Ensuring that all drilling personnel are properly trained and qualified.

- Enforcing all safety rules and regulations, including those related to the use of personal protective equipment.

3. Troubleshooting and Problem Solving

Drilling Inspectors are responsible for troubleshooting and resolving any problems that may arise during drilling operations. Their duties include:

- Identifying and diagnosing drilling problems.

- Developing and implementing solutions to drilling problems.

- Coordinating with other drilling personnel to resolve complex problems.

4. Data Analysis and Reporting

Drilling Inspectors are responsible for collecting, analyzing, and reporting data on drilling operations. Their duties include:

- Collecting and recording drilling data.

- Analyzing drilling data to identify trends and patterns.

- Preparing and submitting drilling reports to management.

Interview Tips

Interviewing for a Drilling Inspector position can be a nerve-racking experience, and the best way to prepare is to know what to expect. Here are some tips for acing your interview:

1. Research the Company and Position

Before the interview, take some time to learn about the company and the specific position you are applying for. This will help you understand the company’s culture, goals, and expectations for the role.

- Visit the company’s website to learn about their history, mission, and values.

- Read industry news and articles to stay up-to-date on the latest drilling technologies and regulations.

- Check out the company’s social media pages to get a sense of their culture and employee engagement.

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to prepare your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer behavioral questions.

- Tailor your answers to the specific job you are applying for.

- Practice your answers out loud so that you can become more comfortable with them.

3. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role.

- Ask questions about the company’s drilling operations.

- Ask questions about the specific challenges and opportunities of the position.

- Ask questions about the company’s culture and values.

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Wear a suit or business casual attire.

- Be on time for your interview.

- Make eye contact and shake hands with the interviewer.

Next Step:

Now that you’re armed with the knowledge of Drilling Inspector interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Drilling Inspector positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini