Are you gearing up for an interview for a Eddy-Current Inspector position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Eddy-Current Inspector and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

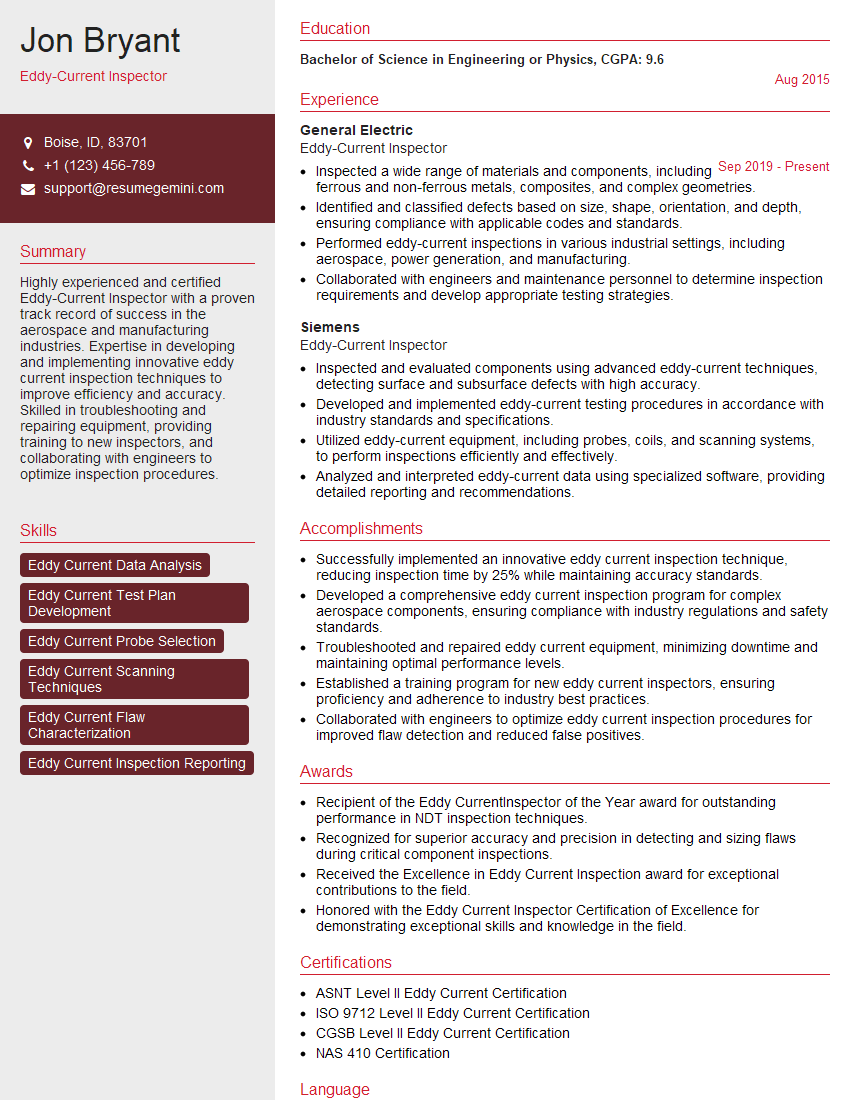

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Eddy-Current Inspector

1. What is the principle behind eddy current inspection and how does it work in detecting defects?

Eddy current inspection is an electromagnetic technique used for detecting defects in conductive materials. It operates on the principle of electromagnetic induction. A probe consisting of a coil is excited with an alternating current, which creates a magnetic field around the coil. When the probe is brought near a conductive material, eddy currents are induced in the material. These eddy currents form their own magnetic field, which interacts with the magnetic field of the probe. The presence of defects in the material, such as cracks, voids, or changes in conductivity, alters the distribution of the eddy currents and their magnetic field. These changes can be detected by the probe and used to identify and characterize the defects.

2. What are the different types of eddy current probes and their applications?

Contact probes

- Direct contact with the surface of the material

- Used to detect surface defects

Proximity probes

- Held a small distance from the surface of the material

- Used to detect both surface and subsurface defects

Internal probes

- Inserted into holes or cavities within the material

- Used to detect defects in inaccessible areas

Rotating probes

- Used for inspecting tubes, pipes, and other cylindrical components

- Provide high-resolution images of the inside surface

3. What are the factors that influence the sensitivity and depth of penetration of eddy current inspection?

- Frequency of the excitation current: Higher frequency increases sensitivity but reduces depth of penetration

- Size and shape of the probe: Larger probes increase depth of penetration but may miss small defects

- Material properties: Conductivity, permeability, and thickness of the material affect eddy current distribution

- Probe-to-surface distance: Closer probes increase sensitivity but may induce probe lift-off effects

- Calibration and standardization procedures: Ensuring accurate and reliable results

4. Describe the process of data acquisition and interpretation in eddy current inspection.

- Data acquisition: Collecting eddy current signals from the probe

- Signal processing: Amplification, filtering, and digitization of the signals

- Feature extraction: Identifying characteristics of the signals that are relevant to defect detection

- Defect characterization: Determining the type, size, and location of defects based on the extracted features

- Reporting: Generating reports that summarize the inspection results and any identified defects

5. What are the advantages and limitations of eddy current inspection?

Advantages

- Non-destructive testing method

- Can detect both surface and subsurface defects

- Can be used on a wide range of conductive materials

- Fast and efficient inspection process

Limitations

- Not suitable for inspecting non-conductive materials

- Depth of penetration limited by material properties and probe design

- May be affected by surface conditions and probe liftoff

- Requires skilled and experienced personnel for reliable results

6. How do you ensure the accuracy and reliability of eddy current inspection results?

- Proper calibration and standardization of equipment

- Following established procedures and protocols

- Using appropriate reference standards and test specimens

- Regular maintenance and calibration of equipment

- Training and certification of personnel

- Independent verification and review of results

7. What are the different applications of eddy current inspection in various industries?

- Aerospace: Inspecting aircraft components for fatigue cracks and corrosion

- Automotive: Testing welded joints, detecting cracks in engine blocks

- Power generation: Inspecting nuclear reactor components, steam generator tubes

- Manufacturing: Testing raw materials, detecting flaws in metal castings and forgings

- Construction: Inspecting rebar in concrete, detecting voids in concrete structures

8. How do you handle challenging inspection scenarios, such as high-temperature environments or inaccessible areas?

- Using specialized probes designed for high-temperature applications

- Employing remote access techniques to reach inaccessible areas

- Adapting inspection procedures to specific circumstances

- Consulting with experts and manufacturers for guidance

9. Stay up-to-date with the latest advancements and developments in eddy current inspection technologies.

- Attending conferences and workshops

- Reading technical journals and publications

- Participating in professional organizations

- Seeking training from manufacturers and industry experts

- Researching new techniques and applications

10. How do you ensure the safety of yourself and others during eddy current inspections?

- Following established safety protocols

- Wearing appropriate personal protective equipment (PPE)

- Inspecting equipment for any damage or defects before use

- Being aware of potential hazards in the inspection environment

- Properly storing and handling equipment

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Eddy-Current Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Eddy-Current Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Eddy-Current Inspection (ECI) is a non-destructive testing method used to detect surface and subsurface defects in conductive materials. Eddy-Current Inspectors operate and maintain ECI equipment, interpret test results, and prepare inspection reports. Key job responsibilities include:

1. ECI Equipment Operation and Maintenance

Inspectors set up, operate, and maintain ECI equipment, including probes, coils, and signal processing units.

- Calibrating and verifying equipment accuracy.

- Selecting appropriate probes and settings for specific inspections.

2. Inspection Planning and Execution

Inspectors plan and execute inspections based on established procedures and specifications.

- Determining inspection coverage and scan patterns.

- Scanning components and recording test data.

3. Data Interpretation and Reporting

Inspectors interpret ECI data to identify and characterize defects.

- Analyzing signal patterns and comparing them to reference standards.

- Preparing inspection reports that document findings and provide recommendations.

4. Quality Assurance and Control

Inspectors maintain quality standards and ensure the accuracy and reliability of inspection results.

- Following established inspection procedures.

- Verifying and documenting the validity of test data.

Interview Tips

To ace an Eddy-Current Inspector interview, follow these tips:

1. Research the Company and Role

Learn about the company’s products, services, and industry. Research the specific role and its requirements to demonstrate interest and knowledge.

- Visit the company website.

- Read industry publications and articles.

2. Highlight Relevant Skills and Experience

Emphasize your ECI experience, including equipment operation, data interpretation, and reporting.

- Provide specific examples of your work.

- Quantify your accomplishments whenever possible.

3. Prepare for Technical Questions

Review basic ECI principles, equipment components, and inspection techniques. Anticipate questions about your understanding of the technology.

- Study technical manuals and industry standards.

- Practice answering questions on ECI theory and applications.

4. Practice Your Communication Skills

ECI Inspectors need strong communication skills to interact with engineers, technicians, and management. Prepare to clearly explain your findings and recommendations.

- Practice presenting your work to a non-technical audience.

- Be prepared to answer questions about your inspection reports.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Eddy-Current Inspector, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Eddy-Current Inspector positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.