Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Fabrication Inspector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Fabrication Inspector so you can tailor your answers to impress potential employers.

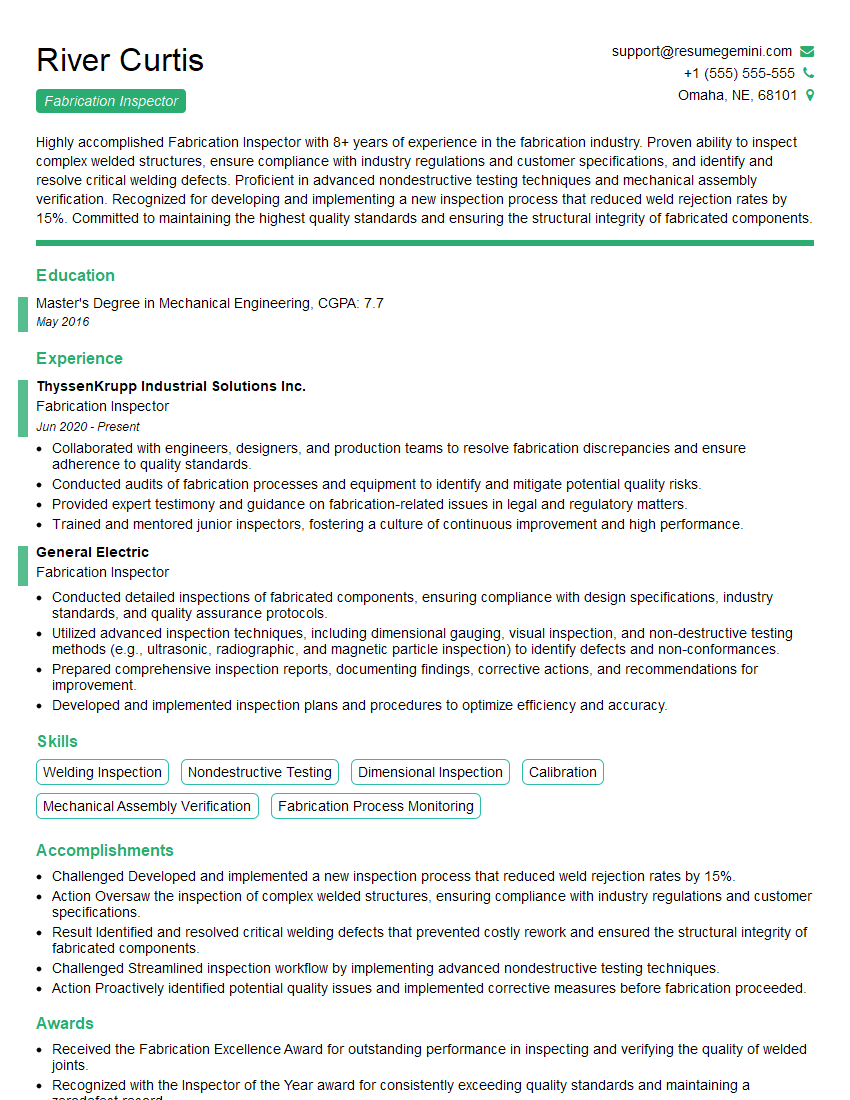

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fabrication Inspector

1. What are the key responsibilities of a Fabrication Inspector?

As a Fabrication Inspector, I am accountable for ensuring the quality and accuracy of fabricated components and assemblies. Key responsibilities include:

- Inspecting fabricated parts, assemblies, and equipment against engineering drawings and specifications

- Verifying dimensions, tolerances, and finishes meet established standards

- Identifying and documenting deviations from specifications

- Working closely with fabricators to resolve discrepancies and ensure corrective actions

- Maintaining accurate and detailed inspection records

2. What are the different types of fabrication processes you have experience with?

Welding

- Arc welding (TIG, MIG, stick)

- Gas metal arc welding (GMAW)

- Gas tungsten arc welding (GTAW)

Machining

- CNC machining

- Lathe work

- Milling

Assembly

- Mechanical assembly

- Electrical assembly

- Piping and plumbing

3. What are the most common defects you encounter during fabrication inspections?

Common fabrication defects include:

- Dimensional inaccuracies

- Welding defects (e.g., undercut, porosity, cracks)

- Surface defects (e.g., scratches, dents, corrosion)

- Assembly errors

- Material defects

4. How do you prioritize inspection tasks when dealing with multiple projects?

To prioritize inspection tasks, I consider several factors:

- Project deadlines and criticality

- Inspection requirements and complexity

- Availability of resources and personnel

- Potential impact of defects on product quality and safety

5. What types of inspection equipment and techniques do you use?

I am proficient in using various inspection equipment and techniques, including:

- Measuring tools (e.g., calipers, micrometers, dial indicators)

- Visual inspection

- Non-destructive testing (e.g., radiography, ultrasonic testing)

- Coordinate measuring machines (CMMs)

6. How do you handle situations where you identify a major defect that could compromise product safety?

Upon identifying a major defect, I take the following steps:

- Document the defect thoroughly, including its location, size, and potential impact

- Inform the appropriate personnel (e.g., supervisor, project manager, quality control)

- Recommend corrective actions based on my analysis of the defect

- Follow up to ensure the defect is resolved effectively

7. What is your understanding of quality control standards and how do you apply them in your work?

I am familiar with various quality control standards, including ISO 9001, AS 9100, and API 570. I apply these standards by:

- Adhering to established inspection procedures and checklists

- Verifying that fabricated components meet specified tolerances and dimensions

- Reviewing inspection reports and ensuring they are accurate and complete

- Participating in quality improvement initiatives

8. How do you stay up-to-date with the latest fabrication techniques and industry best practices?

I stay current with fabrication advancements and best practices through:

- Attending industry conferences and workshops

- Reading technical journals and industry publications

- Networking with colleagues and experts in the field

- Completing continuing education courses

9. What do you find most challenging and rewarding about being a Fabrication Inspector?

Challenging

- Troubleshooting complex inspection issues

- Meeting tight deadlines while maintaining high quality standards

- Working in potentially hazardous environments

Rewarding

- Contributing to product quality and safety

- Solving problems and identifying areas for improvement

- Working with a team to achieve project goals

10. Describe a time when you had to make a difficult decision during an inspection. How did you approach the situation?

In a recent project, I discovered a significant welding defect on a critical component. After careful analysis, I determined that it was not within acceptable limits and posed a safety risk. I faced a difficult decision of whether to reject the component or allow it to be repaired. I consulted with the project manager and engineering team, weighed the potential risks and benefits, and ultimately recommended rejecting the component. This decision was not taken lightly, but it ensured the safety and reliability of the final product.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fabrication Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fabrication Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Fabrication Inspector is a professional responsible for ensuring the quality of fabricated products, adhering to established standards, specifications, and regulations. Here are the key job responsibilities of a Fabrication Inspector:

1. Inspection and Quality Assurance

Conduct thorough inspections of fabricated components, assemblies, and structures to verify adherence to design specifications, drawings, and quality standards.

- Identify and document any defects, deviations, or non-conformities.

- Perform dimensional inspections, visual inspections, and specialized testing (e.g., ultrasonic, radiographic) to assess product quality.

2. Documentation and Reporting

Maintain detailed inspection records and reports, including documentation of findings, test results, and corrective actions taken.

- Prepare inspection certificates, reports, and other documentation as required.

- Communicate inspection results and findings to relevant personnel (e.g., engineers, production supervisors).

3. Quality Control and Improvement

Collaborate with production and engineering teams to identify areas for quality improvement and process optimization.

- Suggest and implement quality control measures to minimize defects and enhance product reliability.

- Participate in root cause analysis and corrective action processes to address quality issues.

4. Compliance and Regulations

Ensure compliance with applicable industry regulations, codes, and standards (e.g., ASME, API, ISO).

- Stay updated on industry best practices and technological advancements in fabrication and inspection.

- Conduct audits and inspections to verify compliance with safety, environmental, and quality regulations.

Interview Tips

Interview preparation is crucial for acing an interview for a Fabrication Inspector position. Here are some tips and hacks to help candidates:

1. Research the Company and Industry

Thoroughly research the company you’re applying to, their industry, and the specific products or projects they specialize in. This knowledge will enable you to align your qualifications with the company’s needs.

2. Highlight Relevant Experience and Skills

Emphasize your experience and skills that are directly relevant to the job responsibilities of a Fabrication Inspector. Quantify your accomplishments with concrete examples, using numbers and percentages to demonstrate the impact of your work.

3. Prepare for Technical Questions

Expect technical questions related to fabrication techniques, inspection methods, and quality control principles. Study industry standards and regulations, and brush up on your knowledge of inspection equipment and testing procedures.

4. Demonstrate Attention to Detail and Critical Thinking

Fabrication Inspectors must have a keen eye for detail and analytical thinking skills. Provide examples in your answers that showcase your ability to identify and resolve quality issues.

5. Emphasize Communication and Collaboration

Effective communication and collaboration are essential. Highlight your experience working with production and engineering teams to improve quality and resolve issues.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Fabrication Inspector, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Fabrication Inspector positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.