Are you gearing up for an interview for a Forming Tube Selector position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Forming Tube Selector and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

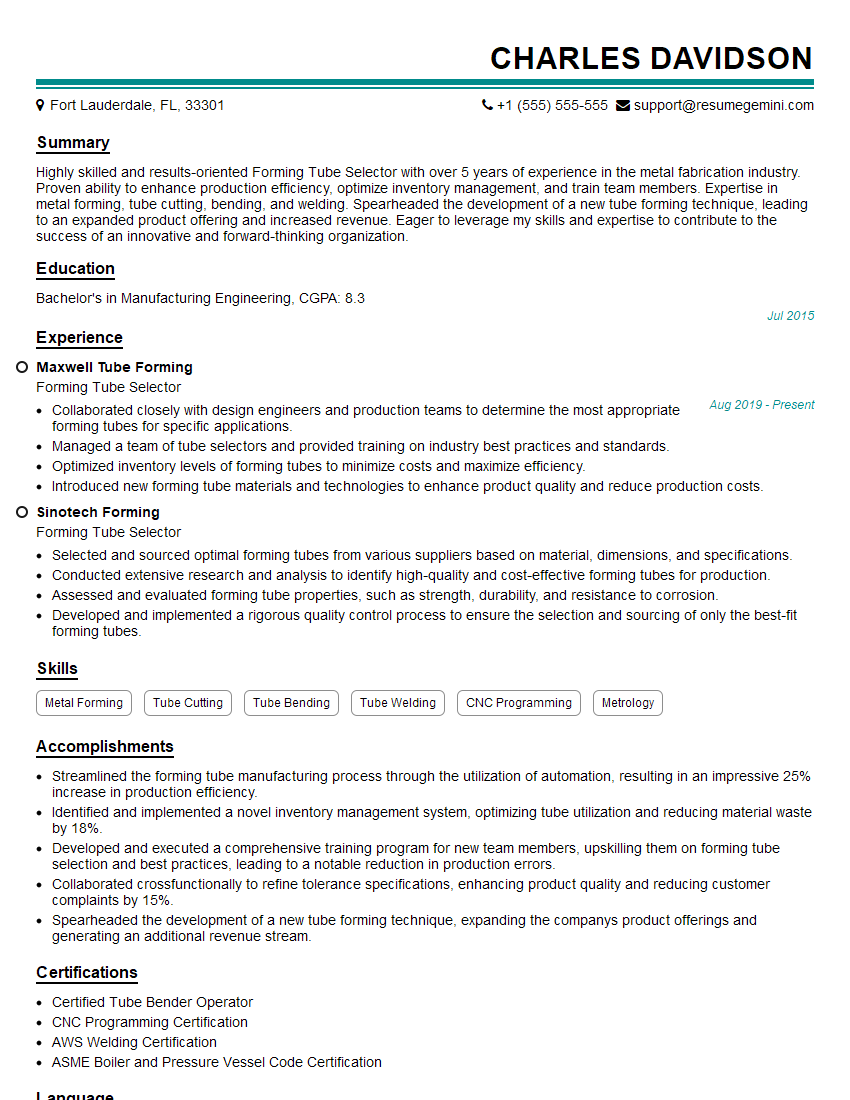

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Forming Tube Selector

1. What is the difference between a cold forming and a hot forming process?

Answer:

- Cold forming is a metalworking process in which metal is shaped at room temperature, without the use of heat.

- Hot forming is a metalworking process in which metal is shaped at elevated temperatures, typically above the recrystallization temperature of the metal.

2. What are the advantages and disadvantages of cold forming?

Answer:

- Cold forming can be used to create complex shapes.

- Cold forming is a relatively inexpensive process.

- Cold forming can be used to create parts with high strength and hardness.

- Cold forming can only be used with certain metals.

- Cold forming can cause work hardening in metals.

- Cold forming can create residual stresses in metals.

Advantages

Disadvantages

3. What are the different types of cold forming processes?

Answer:

- Roll forming

- Press forming

- Extrusion

- Drawing

- Stamping

4. What are the factors that affect the selection of a cold forming process?

Answer:

- The type of metal being formed

- The shape of the part being formed

- The required production volume

- The available equipment

- The cost of the process

5. What are the quality control procedures that are used in cold forming?

Answer:

- Visual inspection

- Dimensional inspection

- Mechanical testing

- Metallurgical testing

6. What is the role of a forming tube selector in a cold forming process?

Answer:

- Select the correct type of tube for the forming process

- Determine the correct forming parameters(such as the forming speed, forming pressure, and forming temperature)

- Monitor the forming process(to ensure that the part is being formed correctly)

- Troubleshoot any forming problems

7. What are the key skills and qualifications that are required for a forming tube selector?

Answer:

- Knowledge of cold forming processes

- Experience in selecting and using forming tubes

- Ability to troubleshoot forming problems

- Strong communication and interpersonal skills

8. What are the challenges that are faced by forming tube selectors?

Answer:

- Selecting the correct type of tube for the forming process

- Determining the correct forming parameters

- Monitoring the forming process

- Troubleshooting forming problems

9. What are the latest trends in cold forming technology?

Answer:

- The use of high-strength steels

- The development of new forming processes

- The use of computer simulation to optimize forming processes

- The use of automation to improve productivity

10. What is the future of cold forming?

Answer:

- Cold forming is expected to continue to grow in popularity

- New forming processes are being developed that will make cold forming even more versatile

- Cold forming is becoming more automated

- Cold forming is becoming more environmentally friendly

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Forming Tube Selector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Forming Tube Selector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Forming Tube Selectors are responsible for selecting and preparing forming tubes for use in the production of metal parts. Their duties include inspecting tubes for defects, measuring and cutting tubes to the required length, and bending and flaring tubes as needed.

1. Inspecting tubes for defects

Before tubes can be used in production, they must be inspected for defects. Forming Tube Selectors visually inspect tubes for any cracks, dents, or other imperfections. They also use gauges to measure the thickness and diameter of tubes to ensure that they meet specifications.

2. Measuring and cutting tubes to the required length

Once tubes have been inspected, they need to be cut to the required length. Forming Tube Selectors use a variety of tools to cut tubes, including saws, shears, and snips. They must be able to measure and cut tubes accurately to ensure that the finished product meets specifications.

3. Bending and flaring tubes as needed

In some cases, tubes need to be bent or flared to create the desired shape. Forming Tube Selectors use a variety of tools to bend and flare tubes, including benders, flaring tools, and hammers. They must be able to bend and flare tubes without damaging them.

4. Maintaining a clean and organized work area

Forming Tube Selectors must maintain a clean and organized work area to ensure that tubes are not damaged during the selection and preparation process. They must also keep their tools and equipment in good working order.

Interview Tips

Preparing for an interview for a Forming Tube Selector position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the company and the position

Before you go to your interview, it is important to do your research on the company and the position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the position. You can find information about the company on their website, social media pages, and Glassdoor.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, regardless of the position you are applying for. These questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

- Do you have any questions for me?

It is important to practice answering these questions in advance so that you can deliver clear and concise answers during your interview.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment. You should also avoid wearing excessive jewelry or makeup.

4. Be on time

Punctuality is important for any interview, but it is especially important for a Forming Tube Selector interview. This is because the interviewer will be looking for candidates who are reliable and punctual.

5. Be confident

Confidence is key in any interview, but it is especially important for a Forming Tube Selector interview. This is because the interviewer will be looking for candidates who are confident in their abilities and who are eager to take on new challenges.

6. Be yourself

It is important to be yourself during your interview. The interviewer will be able to tell if you are being fake, so it is important to be honest and genuine about your qualifications and experience.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Forming Tube Selector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!