Are you gearing up for an interview for a Fuel Verification Technician position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Fuel Verification Technician and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

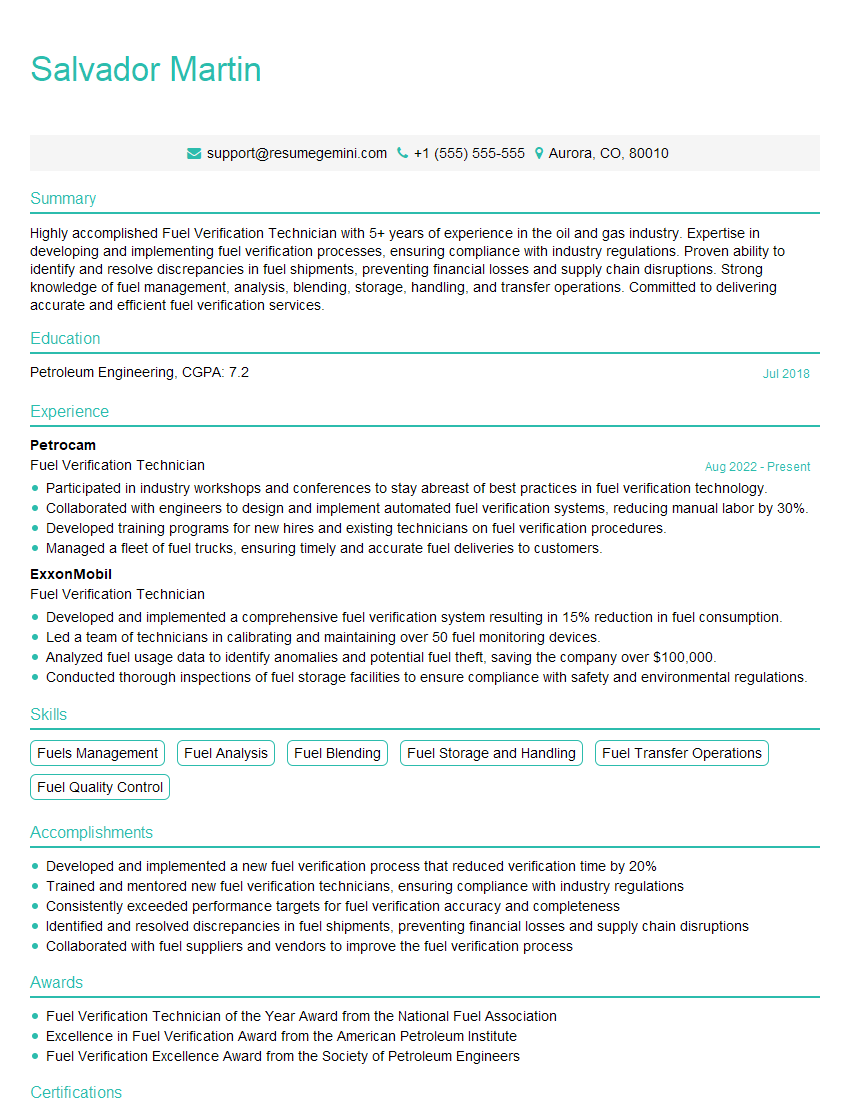

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fuel Verification Technician

1. Could you please describe the fuel verification process you’re familiar with?

The fuel verification process involves meticulously checking the quality and quantity of fuel received at a facility against predefined specifications. It plays a critical role in ensuring that the fuel meets the required standards and specifications, which directly impacts the performance and efficiency of equipment and systems that rely on it. The process typically includes the following key steps:

- Documentation review: Examining accompanying documents such as bills of lading, certificates of analysis, and other relevant paperwork to verify the fuel’s origin, composition, and quantity.

- Physical inspection: Conducting a thorough visual inspection of the fuel, including its color, clarity, and consistency, and checking for any signs of contamination or sediment.

- Sampling: Collecting representative samples of the fuel using appropriate techniques to ensure accuracy and prevent contamination. These samples are then subjected to laboratory analysis to determine their properties and composition.

- Laboratory analysis: Performing a series of tests on the fuel samples to assess their physical and chemical characteristics, such as density, viscosity, flash point, and sulfur content. This analysis helps verify that the fuel meets the specified requirements and standards.

- Data interpretation and reporting: Analyzing the laboratory results and comparing them to established specifications. Generating reports that document the findings and any deviations from the acceptable parameters.

2. What are the most critical aspects of fuel quality to consider during verification?

Factors Related to Fuel Properties:

- Density and viscosity: These properties influence the fuel’s flow characteristics, combustion efficiency, and compatibility with equipment.

- Flash point: Indicates the temperature at which the fuel releases flammable vapors, which is crucial for safety considerations.

- Sulfur content: High sulfur levels can lead to increased emissions and engine wear.

- Cetane number (for diesel fuel): Measures the fuel’s ignition quality and affects engine performance.

- Octane number (for gasoline): Indicates the fuel’s resistance to knocking and pre-ignition.

Factors Related to Fuel Additives:

- Detergents: Help prevent deposits and maintain fuel system cleanliness.

- Antioxidants: Protect the fuel from degradation and oxidation.

- Corrosion inhibitors: Prevent corrosion in fuel tanks and lines.

3. What instrumentation and techniques are commonly used in fuel verification?

- Hydrometers: Measure fuel density.

- Viscometers: Determine fuel viscosity.

- Flash point testers: Assess fuel’s flash point.

- Gas chromatography: Analyzes fuel composition and identifies contaminants.

- Spectrophotometers: Determine fuel color and detect impurities.

- Karl Fischer titrators: Measure water content in fuel.

- Ultrasonic fuel analyzers: Provide real-time monitoring of fuel quality parameters.

4. How do you ensure the accuracy and reliability of your fuel verification results?

- Calibrated equipment: Regularly calibrate all instruments used in fuel verification to ensure their accuracy and precision.

- Standard operating procedures: Adhere to established protocols for sampling, testing, and data recording to minimize errors and maintain consistency.

- Quality control samples: Include quality control samples (e.g., reference fuels) in the analysis to monitor the performance of equipment and techniques.

- Independent verification: Seek independent verification of results from accredited laboratories or external experts to ensure objectivity and accuracy.

- Training and proficiency: Ensure that personnel involved in fuel verification are adequately trained and proficient in the relevant procedures and techniques.

5. What are the potential consequences of accepting non-compliant fuel?

- Equipment damage: Non-compliant fuel can lead to corrosion, fouling, and premature failure of engines, fuel systems, and other components.

- Reduced performance: Inferior fuel quality can result in reduced power output, increased fuel consumption, and decreased efficiency.

- Increased emissions: Non-compliant fuel may contain higher levels of pollutants, contributing to environmental concerns.

- Safety hazards: Fuels that do not meet specifications can pose safety risks, such as increased flammability or instability.

- Warranty issues: Using non-compliant fuel may void warranties on equipment and components.

6. How do you stay updated on the latest fuel specifications and industry best practices?

- Industry publications and conferences: Attend industry conferences, read trade journals, and stay informed about the latest developments in fuel standards and verification techniques.

- Professional organizations: Join professional organizations related to fuel quality and testing, such as ASTM International or the International Council for Standards and Testing.

- Training and workshops: Participate in training programs and workshops to enhance knowledge and skills in fuel verification.

- Collaboration with experts: Network with other fuel verification professionals, consult with industry experts, and seek guidance from reputable laboratories.

7. How do you handle discrepancies between fuel verification results and supplier specifications?

- Communication and documentation: Promptly inform the supplier of any discrepancies and document the issue thoroughly.

- Independent verification: If necessary, send samples to an independent laboratory for confirmation of results.

- Negotiation and resolution: Work with the supplier to resolve the issue, either by rejecting the fuel, negotiating a price adjustment, or agreeing on corrective actions.

- Escalation and reporting: If the issue cannot be resolved directly with the supplier, escalate it to management and regulatory authorities as appropriate.

8. What is your experience with fuel sampling techniques?

- Grab sampling: Collecting fuel samples directly from a tank or pipeline using a sampling device.

- Composite sampling: Combining multiple grab samples taken over a period of time to obtain a representative average sample.

- Automatic sampling: Using automated samplers to collect samples at regular intervals or based on specific triggers.

I have extensive experience in applying these techniques to ensure that fuel samples are collected safely, accurately, and representatively.

9. How do you ensure the integrity of fuel samples during handling and transportation?

- Proper containers: Using clean, sealed, and approved containers to prevent contamination and sample alteration.

- Preservation techniques: Employing appropriate preservation techniques, such as refrigeration or the addition of stabilizers, to maintain sample integrity.

- Chain of custody: Documenting the handling and transportation of samples to maintain accountability and prevent tampering.

- Transportation considerations: Ensuring proper packaging, labeling, and transportation conditions to protect samples from damage or degradation.

10. What is your approach to data management and reporting in fuel verification?

- Data management system: Utilizing a robust data management system to store, organize, and analyze fuel verification data.

- Data validation: Verifying the accuracy and completeness of data before reporting.

- Regular reporting: Generating regular reports that summarize fuel verification results, identify trends, and highlight any non-compliant issues.

- Exception handling: Establishing clear procedures for handling and reporting exceptions or deviations from specifications.

- Communication and transparency: Effectively communicating fuel verification results to stakeholders and ensuring transparency in reporting.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fuel Verification Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fuel Verification Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fuel Verification Technicians play a crucial role in ensuring the accuracy and integrity of fuel transactions, they are responsible for collecting and analyzing data to verify the volume and quality of fuel delivered to customers

1. Data Collection and Analysis

Fuel Verification Technicians are responsible for collecting data from various sources such as flow meters, temperature sensors, and custody transfer documents.

- Utilize specialized equipment and software to collect and analyze data related to fuel volume, temperature, and density.

- Ensure accuracy and reliability of data collection and analysis to support the verification process.

2. Fuel Verification and Reconciliation

Fuel Verification Technicians compare data to verify the quantity and quality of fuel delivered against invoices and contractual agreements.

- Perform calculations and data analysis to determine any discrepancies or variances in fuel volume and quality.

- Reconcile data with invoices, bills of lading, and other relevant documents to ensure accuracy and identify any potential discrepancies.

3. Reporting and Documentation

Fuel Verification Technicians prepare reports and document their findings to provide evidence of fuel verification and reconciliation.

- Prepare detailed reports summarizing fuel verification results, including any identified discrepancies or irregularities.

- Maintain accurate records and documentation to support the verification process and provide a historical reference.

4. Quality Control and Compliance

Fuel Verification Technicians ensure that fuel meets quality standards and complies with regulatory requirements.

- Monitor fuel quality parameters, such as density, viscosity, and water content, to ensure compliance with specifications.

- Participate in quality control procedures and implement corrective actions to mitigate any identified fuel quality issues.

Interview Tips

Preparing for a Fuel Verification Technician interview requires thorough research about the role and the organization. Highlight your skills and experience in fuel verification, data analysis, and quality control.

1. Research the Industry and Organization

Familiarize yourself with the fuel industry, its regulations, and the specific organization you are applying to. Research their business practices, key clients, and industry reputation.

- Study industry publications, websites, and news articles to gain a comprehensive understanding of the field.

- Visit the organization’s website to learn about their history, mission, values, and current projects.

2. Showcase Your Technical Skills

Emphasize your proficiency in data collection, analysis, and fuel verification techniques. Highlight any software or equipment you have experience with, and provide examples of successful projects you have completed.

- Quantify your accomplishments using specific metrics and results to demonstrate your impact.

- Be prepared to discuss your understanding of fuel quality standards and regulatory requirements.

3. Highlight Your Problem-Solving Abilities

Fuel Verification Technicians often encounter discrepancies or irregularities in data. Explain how you approach problem-solving, identify root causes, and develop effective solutions.

- Use the STAR method (Situation, Task, Action, Result) to provide specific examples of how you have successfully resolved issues.

- Discuss your ability to collaborate with cross-functional teams and stakeholders to address complex challenges.

4. Emphasize Attention to Detail

Fuel Verification Technicians must be meticulous and pay close attention to detail. Provide examples of your accuracy and thoroughness in data handling and analysis.

- Explain your quality control processes and how you ensure the reliability of your findings.

- Highlight your ability to identify and address errors or inconsistencies in data.

5. Prepare Questions for the Interviewer

Asking well-informed questions demonstrates your interest and engagement in the role. Prepare thoughtful questions about the organization’s fuel management practices, industry trends, or the specific responsibilities of the Fuel Verification Technician position.

- Questions should be specific and relevant to the job.

- Avoid asking generic questions that can be easily answered through online research.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fuel Verification Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!