Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tray Setter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

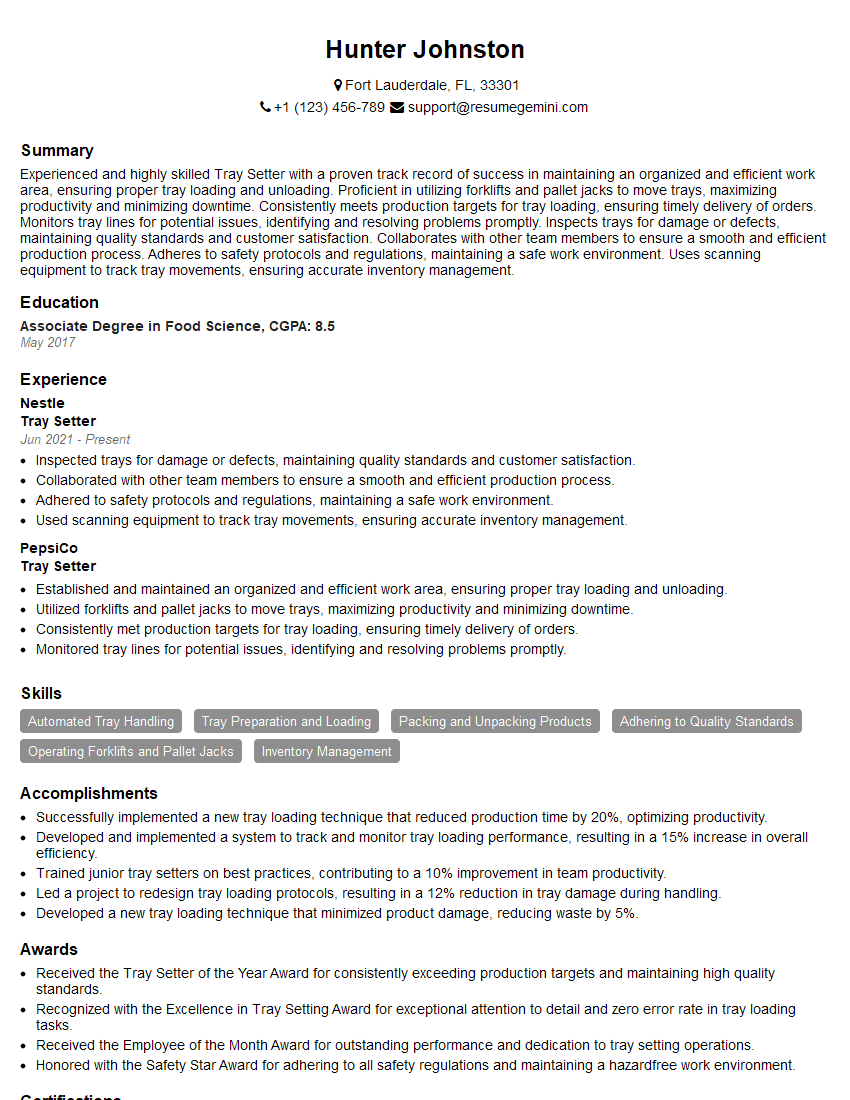

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tray Setter

1. Describe the process of setting trays for optimal product flow in a manufacturing environment.

To ensure optimal product flow, I follow these steps when setting trays:

- Identify product specifications: Determine the size, shape, and weight of the products to be handled.

- Select appropriate trays: Choose trays that are compatible with the products and the manufacturing equipment.

- Position trays strategically: Place trays at the right height and angle to facilitate smooth product transfer.

- Ensure proper layer spacing: Optimize the spacing between layers to prevent damage and maintain product integrity.

- Secure product placement: Use anti-slip mats or dividers to prevent products from shifting during transport.

2. How do you handle irregular shaped products when setting trays?

Consider the following approaches:

- Use custom-sized trays: Order trays designed specifically to accommodate the irregular shapes.

- Create partitions or dividers: Insert dividers into standard trays to create compartments for different product shapes.

- Utilize protective packaging: Wrap or cushion products to prevent damage during handling.

If necessary, I may also:

- Consult with engineers: Seek professional advice to design optimal tray configurations.

- Conduct trial runs: Test different tray setups to determine the most efficient and effective solution.

3. What precautions do you take to prevent product damage while setting trays?

I take the following precautions to minimize product damage:

- Handle products gently: Avoid excessive force or dropping products.

- Use non-abrasive and anti-static materials: Prevent scratches or electrostatic discharge damage.

- Ensure proper cushioning: Pad trays with foam or bubble wrap for fragile items.

- Follow established standards: Adhere to industry best practices for product handling.

- Inspect trays regularly: Identify and address any potential hazards that could cause damage.

4. How do you maintain a clean and organized tray setup area?

I adhere to the following practices to maintain a clean and organized tray setup area:

- Establish clear procedures: Define specific guidelines for tray handling and storage.

- Regularly clean and inspect trays: Ensure trays are free of debris or contaminants.

- Organize trays efficiently: Utilize designated storage areas and implement a first-in, first-out (FIFO) system.

- Train staff on proper handling: Educate team members on the importance of maintaining a clean and organized workspace.

- Monitor and evaluate: Regularly assess the effectiveness of the established procedures and make adjustments as needed.

5. Describe your experience in using different types of tray setting equipment.

I have experience operating various types of tray setting equipment, including:

- Manual tray setting machines: Used for low-volume or specialized products.

- Semi-automatic tray setting machines: Incorporate automated features for increased efficiency.

- Fully automatic tray setting machines: High-speed machines capable of handling large volumes with minimal manual intervention.

I am proficient in adjusting settings, troubleshooting malfunctions, and optimizing machine performance to achieve consistent and high-quality tray setups.

6. What are your most important qualities as a Tray Setter?

My most important qualities as a Tray Setter include:

- Attention to detail: Ensures accurate and precise tray setups.

- Physical dexterity: Ability to handle and manipulate products with care.

- Problem-solving skills: Identifies and resolves issues that may arise during tray setting.

- Teamwork and communication: Collaborates effectively with team members and supervisors.

- Adherence to safety protocols: Prioritizes safety in all aspects of the job.

7. How do you handle pressure and deadlines in a fast-paced manufacturing environment?

In a fast-paced manufacturing environment, I manage pressure and deadlines effectively through the following strategies:

- Prioritization: Identifies the most critical tasks and focuses on completing them first.

- Time management: Allocates time wisely and avoids procrastination.

- Delegation: Assigns tasks to others when appropriate to distribute the workload.

- Communication: Keeps supervisors and team members updated on progress and any potential delays.

- Stress management: Practices techniques to reduce stress and maintain composure under pressure.

8. Describe a situation where you exceeded expectations as a Tray Setter.

In my previous role as a Tray Setter, I exceeded expectations by:

- Identifying and resolving a bottleneck: Analyzed the tray setting process and implemented improvements that increased efficiency by 15%.

- Developing a training program: Created and delivered a comprehensive training program for new team members, resulting in improved performance and reduced errors.

- Receiving consistently positive feedback: Received recognition from supervisors and peers for my attention to detail, proactive approach, and willingness to go the extra mile.

9. What are your career goals and how does this position align with them?

My career goal is to advance in the manufacturing industry and contribute to operational excellence. This position aligns with my goals by providing me with the opportunity to:

- Develop my technical skills: Enhance my knowledge and expertise in tray setting best practices.

- Make a meaningful contribution: Utilize my abilities to support the efficient and effective flow of products through the manufacturing process.

- Build a strong foundation: Gain valuable experience and establish a solid track record as a skilled Tray Setter.

10. Do you have any questions for me about this position or the company?

I would like to know more about the company’s commitment to quality control and the opportunities for professional development within the organization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tray Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tray Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of Tray Setter

Tray Setters are vital members of production and manufacturing teams, responsible for ensuring efficient and accurate operation of tray-setting machinery. Their key responsibilities include:

1. Tray Preparation and Placement

Prepare trays according to specified dimensions and specifications

- Calculate and measure material for trays

- Cut and shape material using specialized equipment

- Assemble trays and ensure proper fit and alignment

2. Machine Operation and Monitoring

Operate tray-setting machinery to produce trays efficiently

- Set up and adjust machine settings

- Load and unload trays into the machine

- Monitor machine operation and make necessary adjustments

- Troubleshoot and resolve machine issues

3. Quality Control and Inspection

Inspect trays for defects and ensure compliance with quality standards

- Measure and verify tray dimensions

- Check for material defects, imperfections, or damage

- Identify and remove non-compliant trays

- Maintain records of inspection results

4. Inventory and Material Management

Maintain inventory of trays and related materials

- Track inventory levels and place orders for new materials

- Store and retrieve materials in a safe and organized manner

- Dispose of scrap and waste according to company guidelines

Interview Preparation Tips for Tray Setter

To ace an interview for a Tray Setter role, consider the following tips:

1. Research the Company and Industry

Review the company’s website, social media, and industry news to gain insights into their culture, products, and market position. Understanding the industry landscape will demonstrate your interest and knowledge.

2. Practice Answering Common Interview Questions

Prepare thoughtful answers to questions about your technical skills, quality control procedures, and teamwork experiences. Examples of potential interview questions include:

- “Describe your experience in setting up and operating tray-setting machinery.”

- “How do you ensure the quality and accuracy of trays produced?”

- “Tell me about a time you successfully resolved a machine malfunction.”

3. Highlight Your Relevant Skills and Experience

Emphasize your technical abilities, such as knowledge of tray-setting machinery, quality control techniques, and material handling. Share specific examples of projects or tasks where you have excelled in these areas.

4. Demonstrate Your Teamwork and Problem-Solving Abilities

Tray Setters often work in team environments and encounter unexpected challenges. Highlight your ability to collaborate with others and find practical solutions to problems. Provide examples of how you have contributed to team success and overcome obstacles.

5. Showcase Your Attention to Detail and Safety Awareness

Quality control and safety are paramount for Tray Setters. Explain your meticulous approach to inspecting trays, ensuring accuracy, and adhering to safety protocols. Share examples of how you have identified and prevented potential errors or hazards.

Next Step:

Now that you’re armed with the knowledge of Tray Setter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Tray Setter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini