Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Furnace Combustion Tester position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

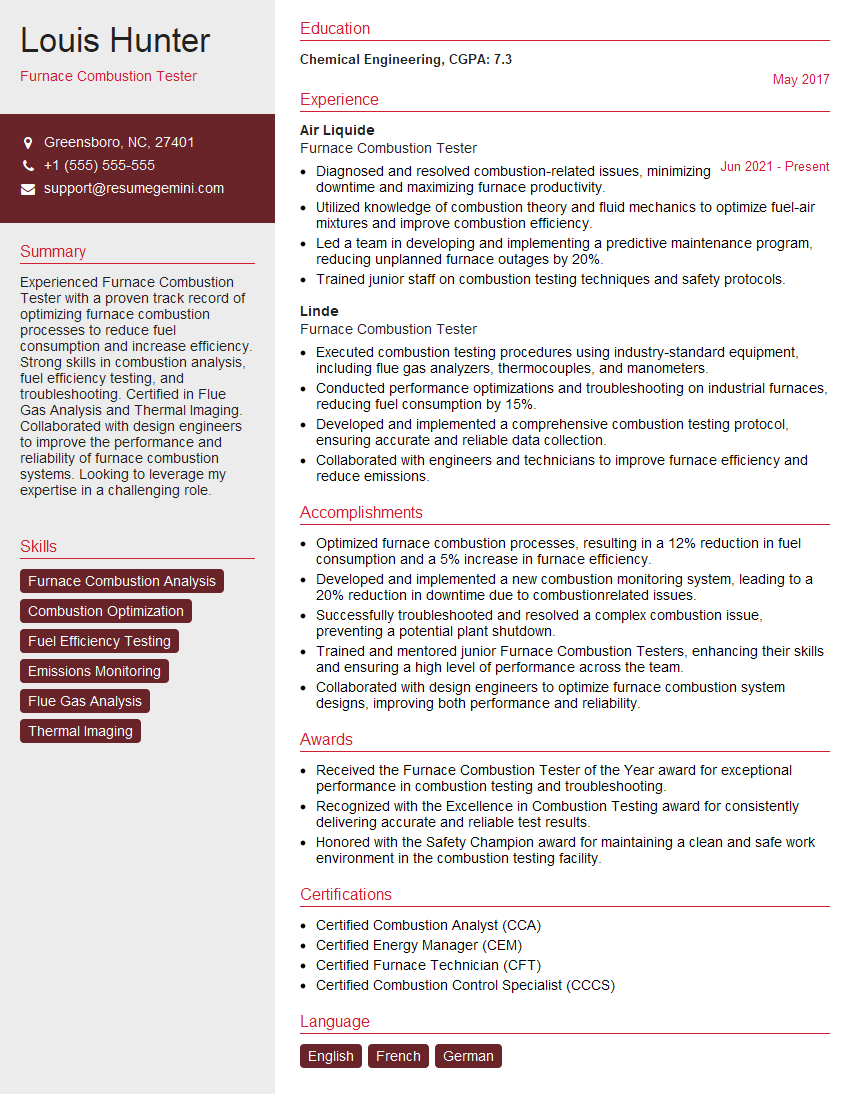

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Furnace Combustion Tester

1. What are the key performance indicators (KPIs) you monitor to ensure efficient combustion in a furnace?

- Flue gas temperature

- Oxygen and carbon monoxide levels

- Fuel-air ratio

- Heat transfer efficiency

2. Describe the techniques you use to optimize combustion efficiency and reduce emissions in furnaces.

Flue gas analysis

- Monitoring oxygen and carbon monoxide levels to determine excess air and combustion efficiency

- Adjusting fuel-air ratio to optimize combustion

Furnace tuning

- Adjusting burner settings, such as flame length and position

- Optimizing air distribution to improve combustion uniformity

3. What types of combustion analyzers do you use and how do you interpret the data they provide?

- Oxygen analyzers: Measure oxygen levels in flue gas

- Carbon monoxide analyzers: Detect incomplete combustion

- Flue gas analyzers: Measure multiple gases, including oxygen, carbon monoxide, nitrogen oxides, and sulfur oxides

Data interpretation

- Use flue gas measurements to calculate combustion efficiency and excess air

- Identify combustion problems based on analyzer readings

4. Explain the principles of combustion stoichiometry and how it affects furnace performance.

- Stoichiometry refers to the balanced chemical equation for combustion.

- The ideal fuel-air ratio ensures complete combustion and minimizes emissions.

- Excess air or insufficient air can impact combustion efficiency and increase pollutant formation.

5. Describe the procedures you follow to troubleshoot and resolve combustion-related issues in furnaces.

- Analyze flue gas data to identify potential issues

- Inspect burners, flame characteristics, and air distribution

- Adjust settings or perform maintenance to correct combustion problems

- Retest and verify improvements after troubleshooting

6. How do you stay updated on the latest advancements in combustion technology and energy efficiency practices?

- Attend industry conferences and workshops

- Read technical publications and research papers

- Participate in professional organizations, such as the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE)

7. Explain the safety protocols and precautions you observe while working with combustion equipment.

- Wear appropriate personal protective equipment (PPE)

- Inspect equipment regularly for any potential hazards

- Follow established lockout/tagout procedures

- Ensure proper ventilation and gas leak detection systems

8. Describe your experience with furnace control systems and how you ensure their optimal performance.

- Familiar with different types of furnace control systems, such as PID controllers and PLC-based systems

- Monitor and adjust control parameters to maintain desired combustion conditions

- Troubleshoot and resolve control system issues

- Work with maintenance teams to ensure proper calibration and maintenance of control systems

9. How do you prioritize and manage multiple projects and tasks simultaneously while maintaining accuracy?

- Develop a structured workflow and task management system.

- Prioritize tasks based on urgency and importance.

- Break down complex tasks into smaller, manageable steps.

- Delegate tasks when necessary and collaborate with colleagues.

10. Describe a challenging project or situation you encountered in your previous role as a Furnace Combustion Tester and how you overcame it.

- Describe the challenge or situation in detail, including the specific technical issue or problem.

- Explain the steps taken to analyze the problem and identify potential solutions.

- Discuss the solution implemented and the positive impact it had on furnace performance or efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Furnace Combustion Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Furnace Combustion Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Furnace Combustion Testers are responsible for testing and evaluating the combustion efficiency of furnaces. They work in a variety of industries, including manufacturing, power generation, and heating and cooling. The primary objective of their role is to ensure that furnaces are operating safely and efficiently, minimizing emissions and maximizing fuel utilization.

1. Combustion Analysis

Furnace Combustion Testers are responsible for analyzing the combustion process in furnaces. They use specialized equipment to measure the temperature, pressure, and composition of gases in the furnace, as well as the flow rates of fuel and air. This information is used to calculate the combustion efficiency of the furnace.

2. Emissions Monitoring

Furnace Combustion Testers are also responsible for monitoring the emissions from furnaces. This includes measuring the levels of pollutants, such as carbon monoxide, nitrogen oxides, and particulate matter, in the exhaust gas. Emissions monitoring is essential for ensuring that furnaces are operating in compliance with environmental regulations.

- They use specialized equipment to measure the concentrations of various pollutants in the exhaust gas.

- The data collected is used to assess the furnace’s compliance with emission regulations and identify areas for improvement.

3. Troubleshooting and Optimization

Furnace Combustion Testers work with engineers and technicians to troubleshoot problems with furnaces. They use their knowledge of combustion processes to identify the cause of problems and develop solutions. They may also make recommendations for optimizing the furnace’s performance.

- They analyze data from combustion tests and identify any inefficiencies or deviations from optimal performance.

- They recommend adjustments to operating parameters, such as fuel-air ratios, to improve combustion efficiency and reduce emissions.

4. Safety and Maintenance

Furnace Combustion Testers must adhere to safety protocols to prevent accidents and protect themselves and others in the workplace.

- They follow established safety procedures for handling hazardous materials and operating equipment.

- They ensure that furnaces are properly maintained and calibrated to ensure accurate measurements.

Interview Tips

Preparing for an interview for the position of Furnace Combustion Tester requires thorough knowledge of the role’s responsibilities, industry-specific terminology, and technical skills. Here are some tips to help candidates ace the interview.

1. Research the Role and Company

Familiarize yourself with the key responsibilities outlined in the job description. Research the company’s background, industry standing, and any relevant projects or initiatives.

2. Highlight Your Technical Expertise

Emphasize your proficiency in combustion analysis techniques, emissions monitoring procedures, and troubleshooting methodologies. Quantify your experience with specific equipment and software.

3. Showcase Your Problem-Solving Skills

Provide examples of how you have successfully identified and resolved combustion-related issues. Describe your analytical approach and the solutions you implemented.

4. Demonstrate Your Commitment to Safety

Stress your commitment to adhering to safety protocols and maintaining a safe work environment. Highlight your experience in handling hazardous materials and ensuring the proper operation of equipment.

5. Be Prepared to Discuss Industry Trends

Stay updated on the latest industry trends and advancements in combustion technology. Discuss your knowledge of emerging technologies and how they can improve furnace efficiency and emissions control.

6. Ask Thoughtful Questions

Prepare insightful questions to ask the interviewer about the company’s combustion-related challenges, the role’s specific expectations, and opportunities for professional development.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Furnace Combustion Tester role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.