Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Furnace Stock Inspector position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

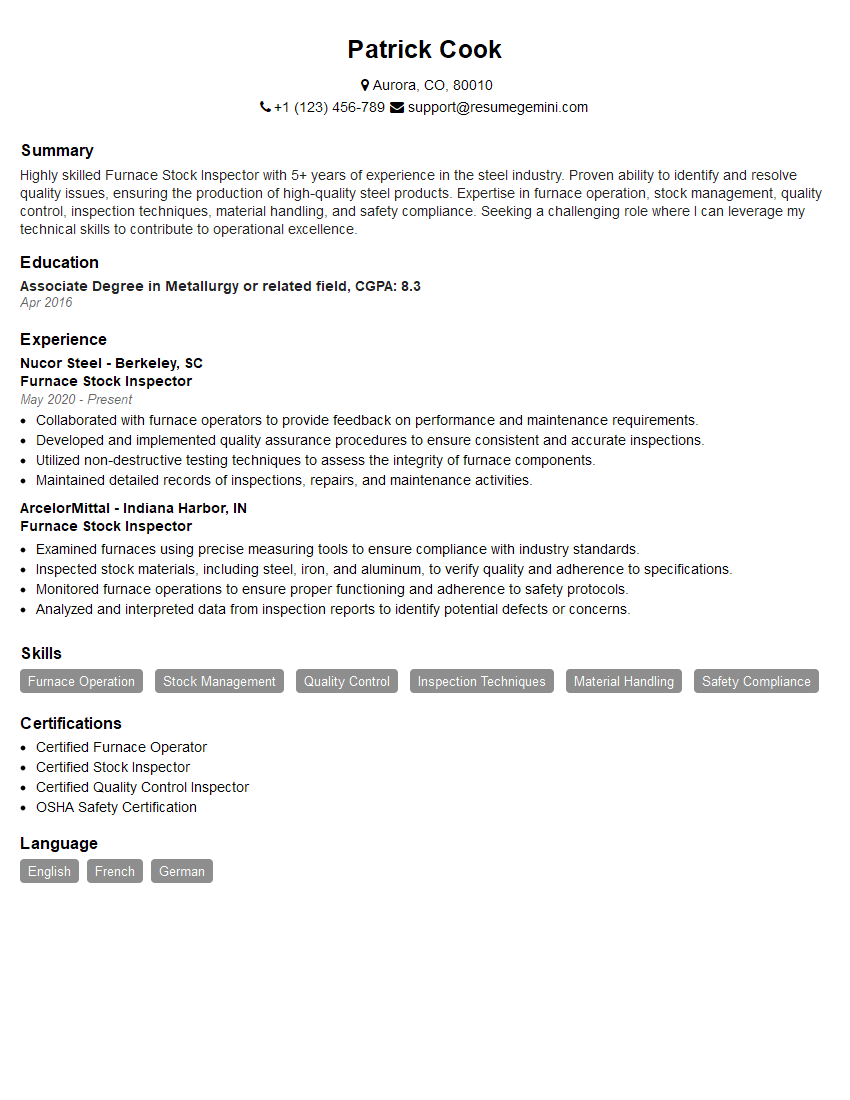

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Furnace Stock Inspector

1. Explain the typical duties and responsibilities of a Furnace Stock Inspector?

The Furnace Stock Inspector is responsible for inspecting raw materials and finished products to ensure they meet specifications. They also monitor the furnace’s operation and make adjustments as needed to maintain optimal performance.

- Inspect raw materials and finished products for defects and compliance with specifications.

- Monitor furnace operation and make adjustments to maintain optimal performance.

- Troubleshoot and resolve any issues with the furnace or related equipment.

- Maintain accurate records of all inspections and calibrations.

- Follow safety protocols and procedures.

2. What are the different types of furnaces used in the industry, and what are their respective advantages and disadvantages?

Electric Arc Furnaces

- Advantages: Fast melting, low operating costs, flexible in terms of feedstock.

- Disadvantages: High energy consumption, electrode consumption, and noise pollution.

Induction Furnaces

- Advantages: Precise temperature control, clean and efficient operation, low maintenance.

- Disadvantages: Slow melting rate, high capital investment, and limited feedstock flexibility.

Gas-Fired Furnaces

- Advantages: Fuel flexibility, high melting rates, and relatively low capital investment.

- Disadvantages: High operating costs, emissions, and noise pollution.

3. What are the key characteristics of a successful Furnace Stock Inspector?

- Strong attention to detail.

- Excellent problem-solving skills.

- Ability to work independently and as part of a team.

- Basic understanding of metallurgy and furnace operations.

- Commitment to safety.

4. Describe the process of conducting a furnace inspection, including the tools and techniques used.

The furnace inspection process typically involves:

- Visual inspection of the furnace’s exterior and interior.

- Measurement of temperatures and pressures.

- Collection and analysis of samples.

- Review of maintenance records.

- Identification and reporting of any defects or potential problems.

Tools and techniques used may include:

- Temperature sensors

- Pressure gauges

- Sampling probes

- Non-destructive testing equipment

- Computerized data acquisition systems

5. How do you ensure the accuracy and reliability of your inspections?

- Use calibrated and certified equipment.

- Follow established inspection procedures.

- Document all findings and observations thoroughly.

- Regularly participate in training and development opportunities.

- Seek feedback from colleagues and supervisors.

6. What are the common defects or problems that you encounter during furnace inspections, and how do you address them?

Common defects or problems include:

- Refractory damage

- Burner malfunctions

- Temperature control issues

- Equipment leaks

To address these issues, I:

- Identify the root cause of the problem.

- Develop and implement a plan for corrective action.

- Monitor the situation to ensure the problem is resolved.

- Document all actions taken.

7. Describe a situation where you identified a potential safety hazard during a furnace inspection, and how you responded.

During a recent inspection, I noticed a crack in the furnace’s refractory lining. This posed a potential safety hazard as it could lead to a furnace failure. I immediately notified my supervisor and the maintenance team. The furnace was shut down and the crack was repaired.

8. What are your thoughts on emerging technologies in the field of furnace inspection, such as the use of drones and AI?

I believe that emerging technologies have the potential to significantly enhance furnace inspections. Drones can provide a more comprehensive and detailed view of the furnace’s interior. AI can be used to analyze data from inspections and identify potential problems early on.

9. How do you stay up-to-date with the latest industry standards and best practices for furnace inspection?

- Attend industry conferences and webinars.

- Read trade publications and technical journals.

- Participate in online forums and discussion groups.

- Network with other professionals in the field.

10. What are your career goals and aspirations?

My career goal is to become a certified Furnace Stock Inspector and to continue to develop my skills and knowledge in the field. I am also interested in pursuing a management role in the future.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Furnace Stock Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Furnace Stock Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Furnace Stock Inspectors play a crucial role in ensuring the quality of steel produced by furnaces. They are responsible for inspecting and testing raw materials and finished products to determine their conformance to specifications. Some of their key job responsibilities include:

1. Raw Material Inspection

Inspecting and testing incoming raw materials, such as iron ore, scrap metal, and fluxes, to ensure they meet quality standards.

- Verifying material composition and physical properties.

- Identifying potential defects or contaminants.

2. Furnace Monitoring

Monitoring the operation of furnaces to ensure they are operating within specified parameters.

- Observing temperature, pressure, and other operating conditions.

- Identifying and reporting any deviations from normal operating procedures.

3. Product Testing

Testing finished steel products, such as bars, sheets, and tubes, to ensure they meet customer specifications.

- Performing physical and chemical tests to assess properties such as strength, hardness, and corrosion resistance.

- Documenting test results and reporting any deviations from acceptable limits.

4. Quality Control

Maintaining a quality control system to ensure the consistency and reliability of steel products.

- Developing and implementing inspection and testing procedures.

- Maintaining records of inspection and test results.

Interview Tips

Preparing thoroughly for a Furnace Stock Inspector interview can significantly increase your chances of success. Here are some tips to help you ace it:

1. Research the Company and Industry

Familiarize yourself with the company’s history, mission, and values. Research the steel industry to understand the current market trends and technological advancements.

- Visit the company’s website and social media pages.

- Read industry news and reports.

2. Practice Your Answers

Prepare answers to common interview questions related to your skills, experience, and motivations. It’s helpful to use the STAR method to structure your responses.

- Situation: Describe the specific situation or task you were involved in.

- Task: Explain your responsibilities and what you were expected to accomplish.

- Action: Outline the actions you took to complete the task.

- Result: Describe the outcome or results of your efforts.

3. Showcase Your Technical Expertise

Highlight your knowledge of steelmaking processes, quality control techniques, and industry standards. Be prepared to discuss specific inspection and testing methods you have experience with.

- Mention any certifications or training you have obtained.

- Provide examples of how you have applied your technical skills to solve problems.

4. Emphasize Your Attention to Detail

Furnace Stock Inspectors must be meticulous and have a strong eye for detail. Emphasize your ability to identify even the smallest deviations from specifications.

- Describe your approach to quality control and data analysis.

- Provide examples of how you have detected and resolved quality issues.

5. Prepare Questions for the Interviewer

Asking well-thought-out questions shows that you are engaged and interested in the position. It also provides you with an opportunity to clarify any aspects of the job.

- Ask about the company’s quality control standards.

- Inquire about opportunities for professional development.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Furnace Stock Inspector, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Furnace Stock Inspector positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.