Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Gauge Inspector position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

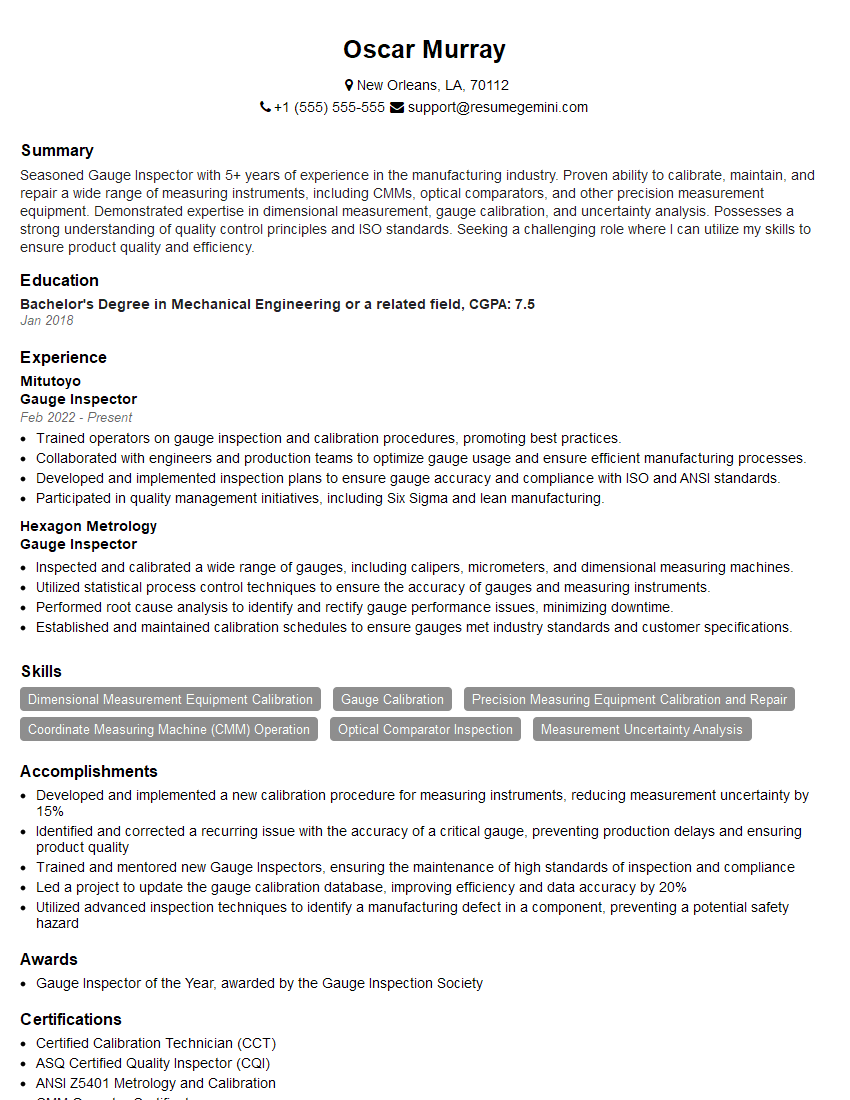

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gauge Inspector

1. What are the key responsibilities of a Gauge Inspector?

The key responsibilities of a Gauge Inspector typically include:

- Inspecting and measuring gauges, tools, and fixtures to ensure their accuracy and conformance to specifications.

- Calibrating and maintaining measuring equipment to ensure its reliability and accuracy.

- Identifying and reporting any discrepancies or non-conformances found during inspections.

- Providing technical support to other departments or teams regarding gauge and measurement-related issues.

- Maintaining records of inspection and calibration activities for traceability and quality control purposes.

2. What types of gauges and measuring instruments are you familiar with?

Mechanical Gauges

- Dial indicators

- Calipers

- Micrometers

- Height gauges

- Squares

Electronic Gauges

- Coordinate measuring machines (CMMs)

- Laser scanners

- Digital calipers

- Digital micrometers

- Vision measuring systems

3. What are the different types of calibration methods used for gauges?

- External calibration: Sending the gauge to an accredited calibration lab for calibration against traceable standards.

- Internal calibration: Using in-house standards and equipment to calibrate gauges within the organization.

- Comparison calibration: Comparing the gauge against another calibrated gauge of known accuracy.

4. What are the critical factors to consider when selecting a gauge for a specific inspection task?

- Accuracy requirements

- Measurement range

- Material properties of the part being inspected

- Environmental conditions

- Availability of calibration and maintenance support

5. What is the importance of traceability in gauge inspection?

Traceability ensures that the measurement results can be linked back to a recognized standard. It helps to maintain the accuracy and reliability of measurements and enables the identification of any potential errors or discrepancies.

6. What are some common error sources in gauge inspection?

- Incorrect calibration of the gauge

- Environmental factors (e.g., temperature, humidity)

- Operator error

- Improper handling of the gauge

- Wear and tear on the gauge

7. How do you ensure that gauge inspection results are accurate and reliable?

- Regular calibration and maintenance of gauges

- Proper training and certification of inspectors

- Following standardized inspection procedures

- Implementing a quality control system

- Regular audits and reviews of inspection processes

8. What are the latest advancements in gauge inspection technology?

- Automated optical inspection (AOI)

- Laser triangulation

- 3D scanning

- Smart gauges with built-in data logging and analysis capabilities

- Advanced statistical process control (SPC) techniques

9. How do you stay up-to-date with the latest industry standards and best practices in gauge inspection?

- Attending industry conferences and webinars

- Reading technical publications and journals

- Participating in professional organizations

- Consulting with experts in the field

- Obtaining relevant certifications and training

10. What is your approach to continuous improvement in gauge inspection processes?

- Regularly reviewing and updating inspection procedures

- Implementing new technologies and techniques

- Collecting and analyzing inspection data

- Seeking feedback from customers and stakeholders

- Encouraging a culture of innovation and problem-solving

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gauge Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gauge Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Gauge Inspector is responsible for maintaining and verifying the accuracy of gauges used in manufacturing processes, ensuring that they meet industry standards and company specifications. Their primary duties include:

1. Gauge Calibration and Verification

Calibrating gauges against certified standards to ensure accuracy and compliance.

2. Gauge Maintenance and Repair

Performing routine inspections, cleaning, and minor repairs to maintain gauge functionality.

3. Data Collection and Analysis

Recording and analyzing calibration data to identify trends and potential issues.

4. Quality Control

Verifying the accuracy of measurements taken using gauges to ensure product quality.

5. Documentation and Reporting

Maintaining detailed records of calibration and maintenance activities, providing reports to management.

Interview Tips

To ace an interview for a Gauge Inspector position, follow these seven tips:

1. Research the Company and Role

Learn about the company’s products, services, and industry. Understand the specific requirements of the Gauge Inspector role and how it fits within the organization.

2. Highlight Your Technical Skills

Emphasize your experience in gauge calibration, maintenance, and inspection. Quantify your accomplishments by providing specific examples and results.

3. Showcase Your Attention to Detail

Gauge Inspectors must be meticulous and detail-oriented. Provide examples of how you have consistently met or exceeded accuracy standards in previous roles.

4. Prepare for Industry-Specific Questions

Review industry regulations and standards related to gauge calibration and inspection. Be prepared to discuss your knowledge of these requirements.

5. Practice Common Interview Questions

Prepare answers to common interview questions such as “Why are you interested in this role?” and “What are your strengths and weaknesses?”

6. Dress Professionally and Arrive on Time

Make a good impression by dressing professionally and arriving on time for your interview. This shows respect for the interviewer and the company.

7. Ask Thoughtful Questions

At the end of the interview, ask insightful questions about the company, the role, or the industry. This demonstrates your interest and engagement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gauge Inspector interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.