Are you gearing up for an interview for a Glass Checker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Glass Checker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

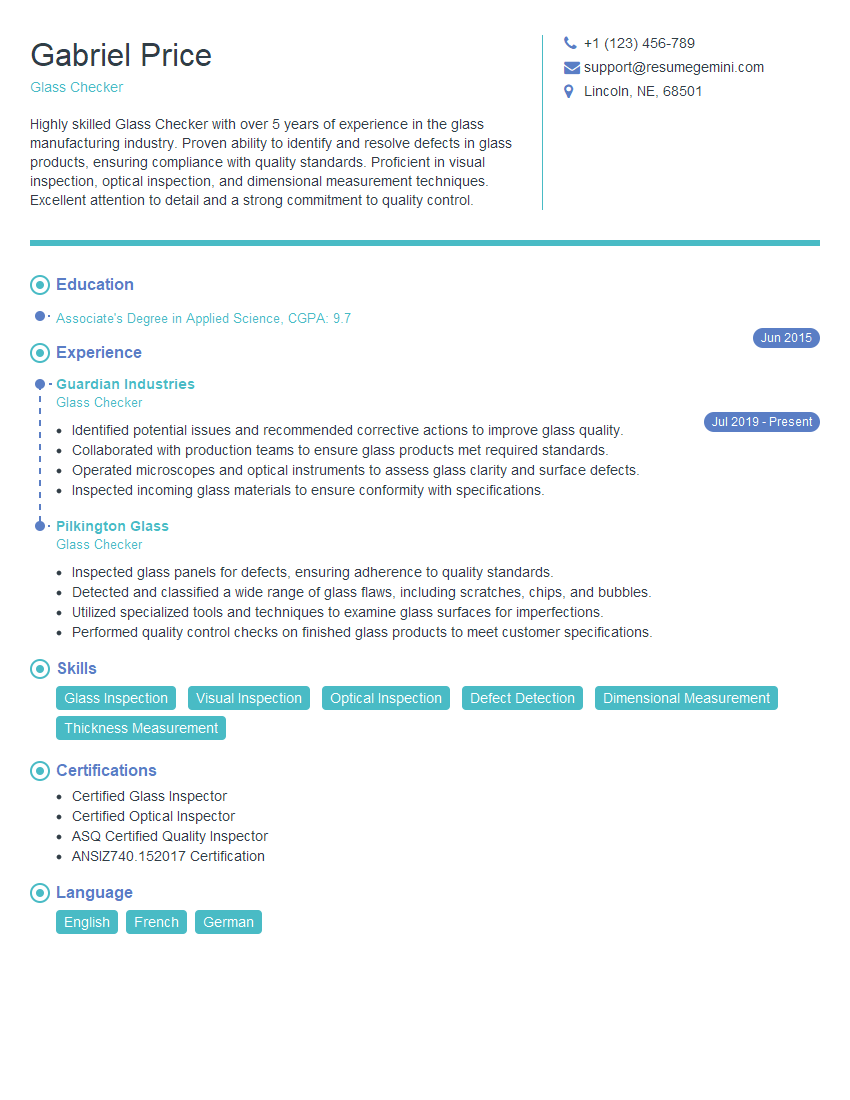

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glass Checker

1. Describe the various types of glass defects you have encountered in your experience and how you identified and resolved them?

- Scratches: Inspected the glass surface for any visible scratches using a magnifier and marked them for repair or replacement.

- Bubbles: Examined the glass for any trapped air bubbles that could weaken its structural integrity and used a bubble removal tool to eliminate them.

- Chips: Assessed the extent of the chip and determined whether it could be repaired using clear epoxy or if the glass needed to be replaced.

- Cracks: Inspected the glass for any hairline cracks that could compromise its strength and recommended immediate replacement to prevent further damage.

- Discoloration: Analyzed the glass for any uneven color distribution or stains and identified the cause, such as chemical reaction or impurities, and suggested appropriate cleaning methods.

2. Explain the ASTM standards that are relevant to your role as a Glass Checker. How do you apply them in your daily work?

- Uses the standard to define and interpret technical terms and abbreviations related to glass manufacturing and testing.

- References the standard to ensure that the glass used in architectural applications meets the required quality and performance specifications.

- Follows the guidelines in the standard to establish standardized procedures for inspecting and testing glass materials.

ASTM C162 Standard Terminology of Glass and Glass Products

ASTM C1048 Standard Specification for Architectural Flat Glass

ASTM C1172 Standard Practice for Inspection and Testing of Glass and Glass Products

3. Describe your experience in using optical measuring devices to assess the quality of glass. Explain how you ensure the accuracy of these measurements.

- Utilized optical comparators to compare glass samples to reference standards, ensuring precise dimension and shape verification.

- Calibrated measuring equipment regularly using certified standards to maintain accuracy and minimize measurement errors.

- Conducted multiple measurements on different areas of the glass to obtain reliable and representative data.

- Followed standardized measurement procedures and recorded data accurately to ensure consistency and traceability.

- Consulted with engineers and quality control personnel to interpret measurement results and determine if they met the specified requirements.

4. Explain the importance of maintaining a clean and organized work environment when inspecting glass. How do you ensure that your workspace is conducive to accurate inspections?

- Regularly cleaned work surfaces and equipment to prevent contamination and minimize the risk of scratches or damage to glass samples.

- Organized tools and materials in a logical and accessible manner to facilitate efficient inspections and prevent accidental spills or breakage.

- Maintained proper lighting conditions to ensure clear visibility and accurate color assessment of glass samples.

- Ensured a dust-free environment by using air purifiers or electrostatic mats to prevent particles from adhering to glass surfaces.

- Wore appropriate clothing and gloves to avoid leaving fingerprints or other contaminants on glass samples.

5. Describe your experience in working with different types of glass, such as tempered, laminated, and annealed glass. How do you adjust your inspection techniques based on the type of glass?

- Inspected for surface scratches, edge chipping, and overall flatness using specialized tools and techniques.

- Examined for delamination, air bubbles, and proper bonding between glass layers using visual and optical inspection methods.

- Assessed for surface defects, color consistency, and thickness using a combination of visual inspection and optical measurement devices.

Tempered Glass

Laminated Glass

Annealed Glass

6. Explain how you document and report your inspection findings. What types of documentation do you typically provide to your supervisors or clients?

- Utilized inspection checklists and forms to record detailed descriptions of defects, measurements, and observations.

- Generated inspection reports that summarized the findings, including images and supporting data as necessary.

- Communicated inspection results to supervisors and clients verbally and in writing to ensure clear understanding and timely follow-up.

- Maintained inspection records for future reference and traceability.

7. Describe your experience in working with customers and addressing their concerns regarding glass quality. How do you build and maintain positive relationships with customers?

- Actively listened to customer concerns and provided clear and informative explanations of inspection findings.

- Collaborated with customers to find mutually acceptable solutions, including repair, replacement, or alternative options.

- Responded promptly to customer inquiries and follow-up requests to demonstrate responsiveness and professionalism.

- Maintained a positive and approachable demeanor, even in challenging situations, to foster trust and open communication.

8. Explain your understanding of the quality control process in glass manufacturing. How do you contribute to maintaining and improving quality standards?

- Collaborated with quality control teams to identify and address potential quality issues at various stages of the manufacturing process.

- Conducted regular inspections and provided feedback to improve production techniques and minimize defects.

- Participated in root cause analysis of quality failures to develop corrective and preventive actions.

- Adhered to established quality control procedures and maintained accurate documentation to ensure traceability and accountability.

9. Describe your experience in using statistical process control techniques to monitor and improve the quality of glass products. How do you interpret and apply statistical data to decision-making?

- Utilized statistical process control charts to monitor key quality parameters, such as thickness, flatness, and surface defects.

- Analyzed statistical data to identify trends, patterns, and potential areas for improvement.

- Collaborated with production teams to implement process adjustments based on statistical findings and reduce variability.

10. Explain your understanding of the safety protocols involved in working with glass. How do you ensure a safe working environment for yourself and others?

- Adhered to personal protective equipment (PPE) requirements, including gloves, safety glasses, and protective clothing.

- Properly handled and stored glass materials to prevent breakage and injury.

- Maintained a clean and organized work area to minimize tripping hazards and reduce the risk of accidents.

- Received regular safety training to stay updated on best practices and emergency procedures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glass Checker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glass Checker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Glass Checkers play a crucial role in ensuring the quality and accuracy of glass products in various industries, such as manufacturing, automotive, and construction.

1. Inspecting and Grading Glass

Glass Checkers meticulously inspect glass products for defects, scratches, bubbles, and other imperfections using specialized equipment. They grade the glass based on industry standards and determine its suitability for specific applications.

2. Measuring and Verifying Dimensions

Glass Checkers ensure that the dimensions of glass products meet the specified requirements. They utilize measuring tools and instruments to verify the accuracy of shapes, sizes, and tolerances.

3. Monitoring Production Line

Glass Checkers monitor the production line to identify any potential issues or deviations in the manufacturing process. They promptly report any irregularities or defects to ensure product quality and process efficiency.

4. Maintaining Records and Documentation

Glass Checkers maintain detailed records and documentation of inspection results, product specifications, and any defects detected. This documentation ensures traceability and accountability in the production process.

5. Providing Feedback and Training

Glass Checkers provide feedback and participate in training programs to improve the overall quality and efficiency of the glass production process. They share their expertise and knowledge with operators and other team members.

Interview Tips

To ace an interview for a Glass Checker position, candidates should focus on showcasing their technical expertise, attention to detail, and commitment to quality.

1. Emphasize Relevant Experience

Highlight your prior experience in glass manufacturing or quality control, emphasizing your skills in inspecting and grading glass products. Quantify your achievements using specific examples.

2. Demonstrate Attention to Detail

Emphasize your strong attention to detail and ability to identify even minor defects in glass products. Describe how your meticulous approach has contributed to quality control and process improvement.

3. Show Commitment to Quality

Express your commitment to delivering high-quality glass products. Showcase your understanding of industry standards and quality management principles, and explain how you have consistently exceeded expectations.

4. Highlight Teamwork Skills

Glass Checkers often work in teams. Highlight your experience collaborating with others, contributing to problem-solving, and ensuring the effective flow of information.

5. Prepare for Technical Questions

Review common technical questions related to glass inspection, grading, and quality control. Be prepared to discuss different types of glass defects, measuring techniques, and documentation practices.

Next Step:

Now that you’re armed with the knowledge of Glass Checker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Glass Checker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini