Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hop Weigher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

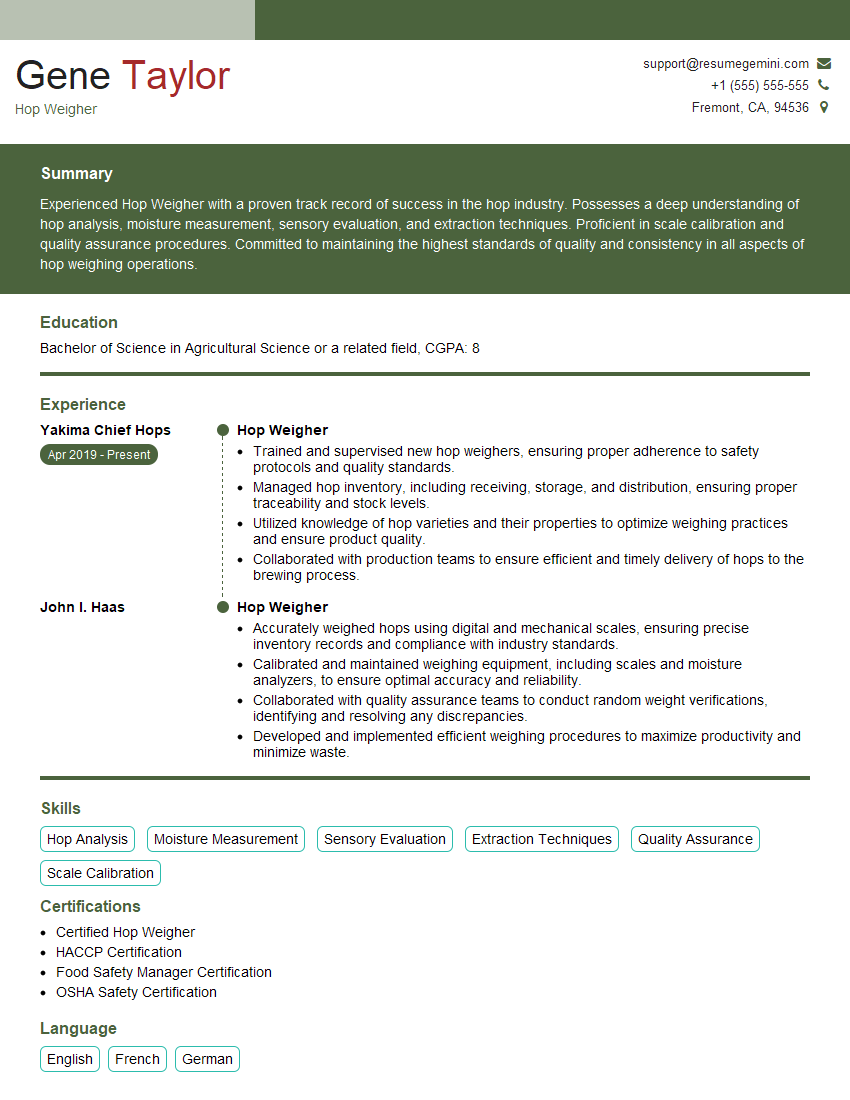

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hop Weigher

1. Could you tell me more about your experience in weighing and measuring hops?

In my previous role at [Brewery Name], I was responsible for weighing and measuring all hops used in the brewing process. This involved using a variety of scales and measuring devices to ensure that the correct amount of hops was added to each batch of beer. I also maintained a detailed record of all hops weighed and measured, to ensure accuracy and consistency.

2. What are the different types of scales and measuring devices used for weighing hops?

Digital scales

- These are the most common type of scale used for weighing hops. They are accurate and easy to use, and can be used to weigh a variety of weights.

Balance beam scales

- These scales are also accurate, but they can be more difficult to use than digital scales. They are best suited for weighing small amounts of hops.

Mechanical scales

- These scales are the least accurate of the three types, but they are also the most affordable. They are best suited for weighing large amounts of hops.

3. What are the different factors that can affect the accuracy of a scale or measuring device?

- The calibration of the scale or measuring device

- The temperature of the environment

- The humidity of the environment

- The vibration of the environment

- The skill of the operator

4. What are the different methods used to calibrate a scale or measuring device?

- Using a known weight

- Using a calibration weight

- Using a calibration service

5. What are the different types of hops and how do they differ in terms of weight and size?

- Aroma hops: These hops are used to provide flavor and aroma to beer. They are typically lighter in weight and smaller in size than bittering hops.

- Bittering hops: These hops are used to provide bitterness to beer. They are typically heavier in weight and larger in size than aroma hops.

- Dual-purpose hops: These hops can be used for both flavoring and bittering. They are typically medium in weight and size.

6. What are the different ways to store hops and how do these methods affect their quality?

- Whole leaf hops: These hops are stored in their natural form, with the leaves and stems intact. They are the most flavorful type of hops, but they can also be the most expensive.

- Pelletized hops: These hops are made from whole leaf hops that have been ground into a powder. They are less flavorful than whole leaf hops, but they are also more affordable and easier to use.

- Extract hops: These hops are made from whole leaf hops that have been boiled and concentrated. They are the least flavorful type of hops, but they are also the most affordable and easiest to use.

7. What are the different factors that can affect the quality of hops?

- The variety of hops

- The growing conditions

- The harvesting methods

- The storage conditions

8. What are the different ways to use hops in the brewing process?

- Adding hops to the boil: This is the most common way to use hops. Hops added to the boil will contribute both bitterness and flavor to the beer.

- Dry hopping: This is a process of adding hops to the beer after fermentation. Dry hopping will contribute flavor and aroma to the beer, but it will not add bitterness.

- Steeping hops: This is a process of soaking hops in hot water for a period of time. Steeping hops will contribute flavor and aroma to the beer, but it will not add bitterness.

9. What are the different types of equipment used in the hop weighing and measuring process?

- Digital scales

- Balance beam scales

- Mechanical scales

- Hopper bins

- Conveyors

- Baggers

10. What are the different safety procedures that must be followed when working with hops?

- Wear appropriate protective clothing, including gloves, a dust mask, and eye protection.

- Work in a well-ventilated area.

- Avoid contact with skin and eyes.

- Wash hands thoroughly after handling hops.

- Store hops in a cool, dry place.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hop Weigher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hop Weigher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hop Weighers play a critical role in the production process of breweries by ensuring the accurate weighing and recording of hops, a key ingredient in beer production.

1. Weighing and Recording Hops:

The primary responsibility involves weighing hops using calibrated scales or automated weighing systems.

- Precisely determine the weight of hops in accordance with production specifications.

- Maintain accurate records of hop weights and quantities received and used.

2. Quality Control and Inspection:

Hop Weighers are responsible for inspecting hops for quality and consistency before weighing.

- Inspect hops for defects, contamination, or any other quality issues.

- Follow established quality standards and procedures to ensure the integrity of hops used in brewing.

3. Equipment Maintenance and Calibration:

Maintaining and calibrating weighing equipment is crucial for accurate measurements.

- Perform regular maintenance and calibration of weighing scales and systems.

- Ensure that equipment is functioning correctly and meeting required accuracy standards.

4. Compliance and Documentation:

Hop Weighers must adhere to industry regulations and document all weighing and inspection procedures.

- Comply with regulatory standards and record-keeping requirements for hop weighing and quality control.

- Maintain detailed records and reports for traceability and auditing purposes.

Interview Preparation Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are a few key tips and hacks to help you ace your Hop Weigher interview:

1. Research the Company and Role:

Before the interview, take the time to research the brewery you’re applying to and the specific Hop Weigher role.

- Visit the company’s website and social media pages to learn about their culture, values, and products.

- Thoroughly review the job description to understand the responsibilities, requirements, and expectations of the role.

2. Highlight Relevant Skills and Experience:

Emphasize your skills and experience that are most relevant to the Hop Weigher position.

- Showcase your precision and accuracy in weighing and recording materials.

- Highlight your ability to inspect and assess product quality.

- Mention any previous experience in the brewing industry or with hop handling.

3. Practice Common Interview Questions:

Anticipate and prepare for common interview questions related to the Hop Weigher role.

- Describe your experience in weighing and measuring materials.

- How do you ensure the accuracy and reliability of weighing equipment?

- Explain your understanding of the quality control standards for hops.

4. Demonstrate Enthusiasm and Passion:

Convey your genuine interest and passion for the brewing industry and the Hop Weigher role.

- Share your knowledge about the different types of hops and their impact on beer production.

- Express your eagerness to learn more about the brewing process and contribute to the company’s success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hop Weigher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!