Are you gearing up for an interview for a Hull Inspector position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Hull Inspector and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

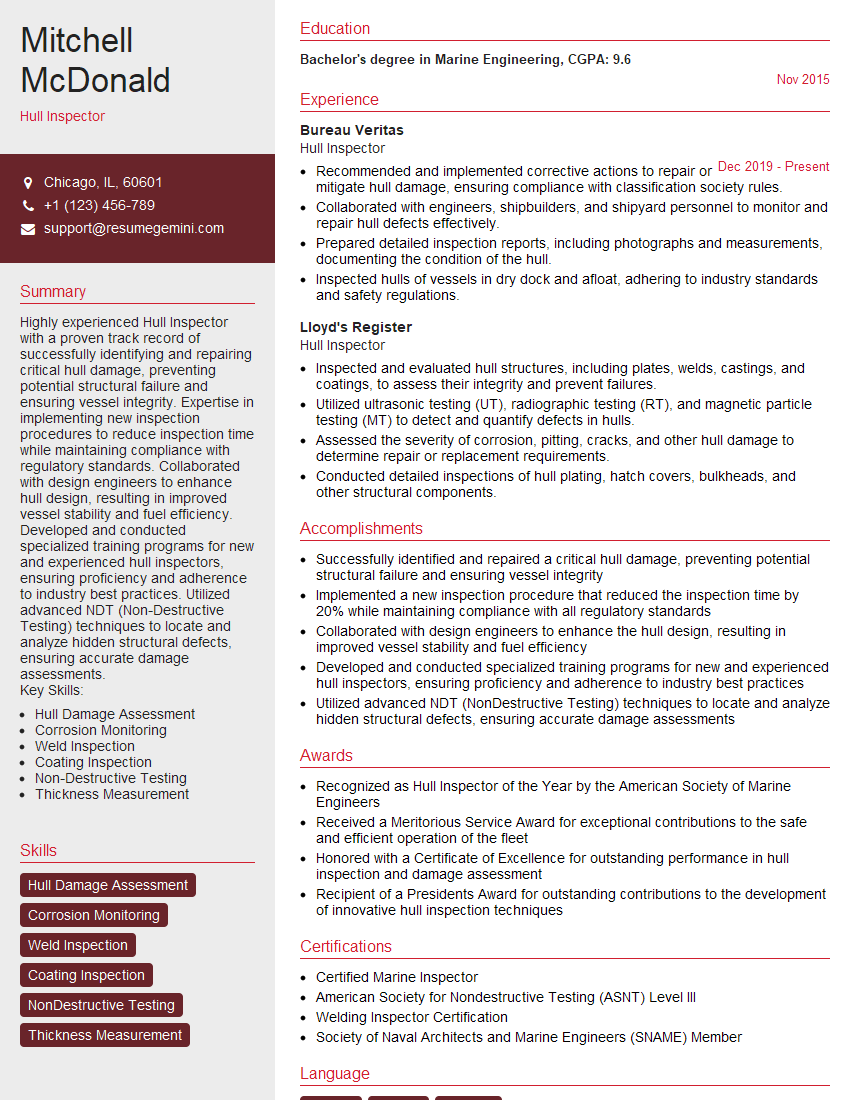

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hull Inspector

1. How do you conduct a general hull inspection?

In a general hull inspection, I follow a systematic approach that covers various aspects of the hull:

- Pre-Inspection Planning:

- Review vessel documentation, drawings, and repair history.

- Identify areas of concern and prioritize inspection based on risk assessment.

- Visual Inspection:

- Examine the hull surface for any visible damage, such as cracks, dents, or corrosion.

- Inspect welds, seams, and joints for structural integrity.

- Thickness Measurement:

- Use ultrasonic thickness gauges to measure hull plate thickness and identify areas of thinning.

- Compare readings to established acceptance criteria.

- Corrosion Inspection:

- Inspect for rust, pitting, and other forms of corrosion on the hull.

- Assess the extent and severity of corrosion using non-destructive testing methods.

- Reporting and Recommendation:

- Document all findings during the inspection.

- Provide recommendations for repairs, maintenance, or further investigation as necessary.

2. Explain the different types of hull coatings and their applications.

Antifouling Coatings:

- Prevent the growth of marine organisms on the hull, reducing drag and fuel consumption.

- Types: Biocidal coatings, foul-release coatings, self-polishing coatings.

Barrier Coatings:

- Protect the hull from corrosion and other environmental factors.

- Types: Epoxy coatings, polyurethanes, vinyls.

Specialist Coatings:

- Designed for specific purposes, such as ice protection, cathodic protection, or chemical resistance.

- Types: Ice-resistant coatings, cathodic protection coatings, chemical-resistant coatings.

3. How do you use thickness measurements to assess the structural integrity of a hull?

- Identify Areas of Concern: Use historical data, known damage locations, or areas with reduced accessibility to prioritize thickness measurements.

- Establish Acceptance Criteria: Determine acceptable hull thickness based on vessel class, age, and operating conditions.

- Perform Measurements: Use ultrasonic thickness gauges to measure the thickness of hull plates at specified locations.

- Analyze Readings: Compare measured thicknesses to acceptance criteria. Identify areas with significant thinning or below-standard thickness.

- Assess Structural Integrity: Evaluate the extent and severity of thinning. Consider factors such as plate thickness, corrosion rates, and vessel operation to assess the overall structural integrity.

4. Describe the process of cathodic protection in preventing hull corrosion.

- Principle: Sacrificial anodes or impressed current systems are used to create an electrochemical reaction that protects the hull metal from corrosion.

- Sacrificial Anodes: Made of a metal more reactive than the hull (e.g., zinc or aluminum), sacrificial anodes corrode preferentially, protecting the hull.

- Impressed Current Systems: Use external power sources to provide a cathodic current to the hull, protecting it from corrosion.

- Monitoring and Maintenance: Regularly inspect and measure anode consumption or current output to ensure adequate protection.

5. What are the common types of hull damage and their potential causes?

- Abrasion: Caused by contact with hard objects, such as rocks, piers, or ice.

- Corrosion: Electrochemical reaction between the metal hull and the marine environment.

- Fatigue: Accumulation of stress from repeated loads or vibrations.

- Denting: Caused by impacts or collisions.

- Cracking: Structural failure due to excessive stress or fatigue.

- Pitting: Localized corrosion that creates small holes in the hull.

6. How do you inspect and assess hull welds for defects?

- Visual Inspection: Examine welds for proper shape, alignment, and any visible defects.

- Magnetic Particle Inspection: Use magnetic fields and magnetic particles to detect surface and near-surface cracks and inclusions.

- Radiography Testing: Use X-rays or gamma rays to penetrate the weld and reveal internal defects.

- Ultrasonic Testing: Use sound waves to detect internal defects, such as cracks, voids, and laminations.

7. Explain the role of non-destructive testing (NDT) techniques in hull inspection.

- Revealing Hidden Defects: NDT techniques, such as ultrasonic testing and radiography, allow for the detection of internal defects that may not be visible to the naked eye.

- Minimizing Invasive Inspections: NDT techniques provide a non-destructive means of evaluating hull integrity, reducing the need for intrusive inspections.

- Accurate Assessment: NDT techniques provide quantitative data on defect size, shape, and location, enabling accurate assessment of their severity.

- Predictive Maintenance: Regular NDT inspections can identify potential defects early on, allowing for proactive maintenance and preventing catastrophic failures.

8. Describe the process of underwater hull inspection and the challenges involved.

- Preparation: Plan the inspection, assemble equipment, and ensure safety measures.

- Diving Procedures: Use specialized diving equipment and techniques to navigate the underwater environment.

- Inspection Methods: Visual inspection, NDT techniques (e.g., ultrasonic testing), and photography to document findings.

- Challenges: Limited visibility, currents, marine growth, and potential hazards can make underwater inspections challenging.

9. How do you prioritize repair recommendations after a hull inspection?

- Safety and Structural Integrity: Prioritize repairs that address immediate safety concerns or structural deficiencies.

- Corrosion Prevention: Focus on repairs that prevent further corrosion and protect the hull’s long-term integrity.

- Operational Impact: Consider the impact of repairs on vessel performance, efficiency, and availability.

- Cost and Scheduling: Take into account the cost and scheduling implications of different repair options.

- Regulatory Compliance: Ensure that repair recommendations meet regulatory requirements and industry standards.

10. Describe the importance of regular hull inspections and their impact on vessel safety and operation.

- Early Detection of Defects: Regular inspections allow for the early detection of hull defects, preventing their escalation into more significant problems.

- Proactive Maintenance: Inspections enable proactive maintenance planning, reducing the risk of costly repairs and unplanned downtime.

- Ensured Vessel Safety: By identifying and repairing hull defects, regular inspections contribute to the safety of the vessel and its crew.

- Compliance with Regulations: Inspections ensure compliance with regulatory requirements for vessel safety and environmental protection.

- Enhanced Operational Efficiency: A properly maintained hull reduces drag and fuel consumption, improving vessel efficiency and reducing operating costs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hull Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hull Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hull Inspectors are responsible for ensuring the safety and integrity of ships and other marine vessels. They inspect hulls, decks, and other structural components for damage, wear, and corrosion. They also ensure that all repairs and maintenance are carried out to a high standard.

1. Inspect hulls, decks, and other structural components for damage, wear, and corrosion

Hull Inspectors use a variety of tools and techniques to inspect hulls, decks, and other structural components. They may use visual inspections, ultrasonic testing, or magnetic particle testing to identify defects. They also inspect welds, seams, and other areas that are prone to damage.

2. Ensure that all repairs and maintenance are carried out to a high standard

Hull Inspectors are responsible for ensuring that all repairs and maintenance are carried out to a high standard. They inspect all repairs and maintenance work to ensure that it meets the required specifications. They also ensure that all repairs and maintenance are carried out in a timely manner.

3. Prepare reports and documentation

Hull Inspectors prepare reports and documentation on their inspections. These reports include details of any damage or defects found, as well as recommendations for repairs or maintenance. Hull Inspectors also maintain records of all inspections and repairs.

4. Stay up-to-date on industry standards and regulations

Hull Inspectors must stay up-to-date on industry standards and regulations. They must be familiar with the latest safety standards and regulations, as well as the latest inspection techniques and procedures.

Interview Tips

Preparing for an interview for a Hull Inspector position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the position. You can find information about the company on their website, in industry publications, and on social media.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely. You can also prepare for specific questions about your experience and qualifications.

3. Be prepared to talk about your experience and qualifications

The interviewer will want to know about your experience and qualifications, so be prepared to talk about them in detail. Highlight your skills and experience that are relevant to the position you are applying for. You can also talk about your education and training, as well as any certifications or licenses you have.

4. Be prepared to ask questions

Asking questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the position. Prepare a few questions to ask the interviewer, such as “What are the biggest challenges facing the company right now?” and “What is the company’s culture like?”.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Hull Inspector role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.