Are you gearing up for an interview for a Inked Ribbons Quality Control Technician position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Inked Ribbons Quality Control Technician and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

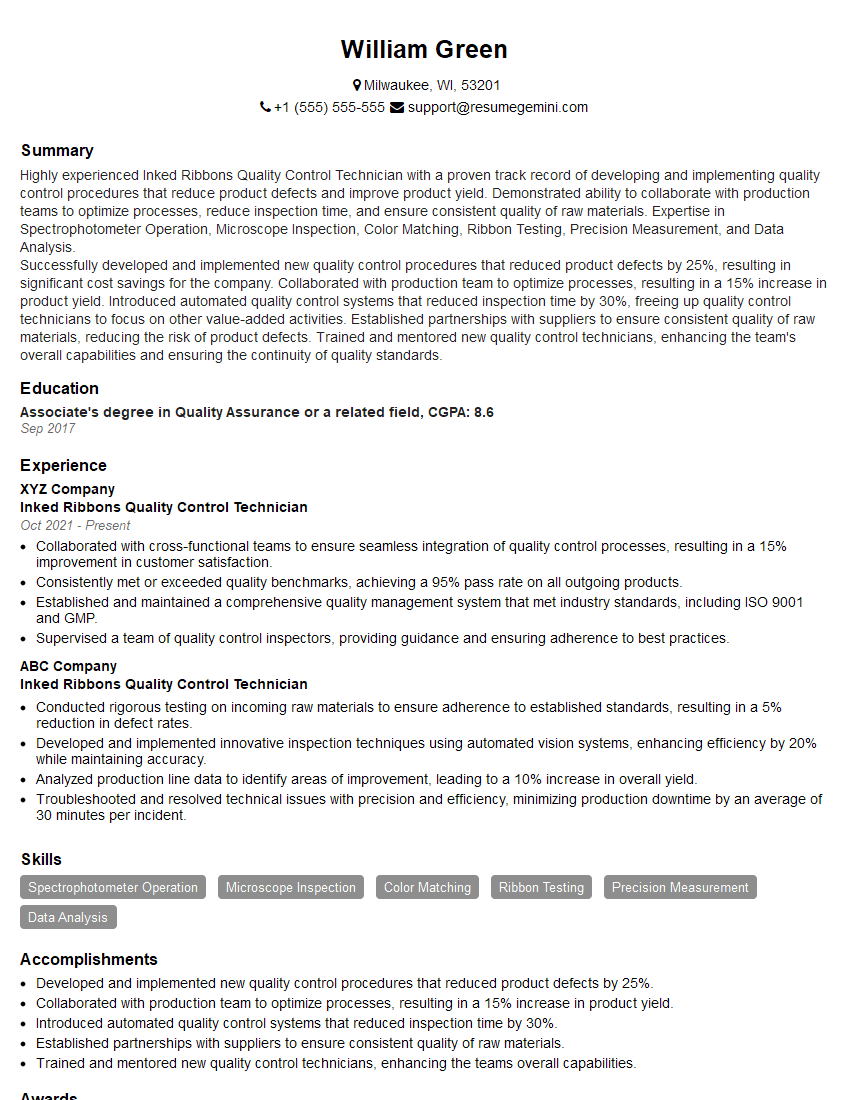

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Inked Ribbons Quality Control Technician

1. What are the key responsibilities of an Inked Ribbons Quality Control Technician?

As a Quality Control Technician for Inked Ribbons, my primary responsibilities include:

- Inspecting and testing inked ribbons to ensure they meet quality standards.

- Identifying and correcting defects in the manufacturing process.

- Maintaining accurate records of quality control checks and findings.

- Collaborating with the production team to improve quality and efficiency.

- Staying up-to-date with industry best practices and quality control techniques.

2. Can you describe the different types of tests you perform as an Inked Ribbons Quality Control Technician?

The various types of tests I conduct include:

Physical Inspection:

- Visual examination for color, clarity, and physical integrity.

- Measuring dimensions and tolerances.

- Assessing the ribbon’s durability and resistance to wear and tear.

Printing Quality Tests:

- Evaluating print clarity, sharpness, and color reproduction.

- Testing for bleed-through and ghosting.

- Analyzing the ribbon’s compatibility with different printer models.

3. What are some common defects you encounter in inked ribbons, and how do you address them?

Common defects I encounter include:

- Color Variations: Adjusting ink formulations or checking printer settings.

- Clarity Issues: Identifying and eliminating impurities in the manufacturing process.

- Bleeding: Modifying ink composition or adjusting coating thickness.

- Ghosting: Enhancing bonding techniques or using different ribbon materials.

- Durability Concerns: Improving material selection or reinforcing the ribbon structure.

4. How do you ensure the accuracy and precision of your quality control measurements?

I adhere to strict quality control protocols to ensure accuracy and precision:

- Calibrating testing equipment regularly.

- Following documented inspection and testing procedures.

- Using standardized reference materials and samples.

- Maintaining detailed records of all measurements and observations.

- Participating in interlaboratory comparisons to verify results.

5. What statistical tools do you use for quality data analysis?

I am proficient in applying statistical tools for data analysis, including:

- Statistical Process Control (SPC) charts to monitor and analyze process variability.

- Hypothesis testing to assess the significance of quality differences.

- Correlation and regression analysis to identify relationships between variables.

- Design of Experiments (DOE) to optimize quality parameters.

6. How do you prioritize and manage your workload as a Quality Control Technician?

I prioritize my workload based on the criticality of the tasks:

- Identifying urgent quality issues that require immediate attention.

- Scheduling routine inspections and tests according to established schedules.

- Allocating time for data analysis and reporting.

- Coordinating with the production team to resolve quality concerns efficiently.

7. What continuous improvement initiatives have you implemented to enhance quality control processes?

I am committed to continuous improvement and have implemented several initiatives, such as:

- Establishing a system for recording and tracking quality deviations.

- Developing and implementing corrective action plans to address root causes of defects.

- Collaborating with suppliers to improve the quality of incoming materials.

- Introducing automation to streamline quality control processes.

8. Describe your experience with quality management systems, such as ISO 9001.

I have a thorough understanding of ISO 9001 and have played a key role in implementing and maintaining such systems:

- Developed and documented quality policies and procedures.

- Conducted internal audits to assess compliance with the quality management system.

- Collaborated with external auditors during certification audits.

9. How do you stay up-to-date with emerging quality control techniques and industry best practices?

I stay informed about advancements in quality control through:

- Attending industry conferences and workshops.

- Reading technical journals and publications.

- Participating in online forums and discussion groups.

- Seeking professional development opportunities in quality control.

10. Describe a challenging situation you faced as an Inked Ribbons Quality Control Technician and how you overcame it.

During a large production run, I encountered a recurring issue with print clarity. After thorough investigation, I discovered an inconsistency in the coating process. I worked closely with the production team to identify the root cause and implement corrective measures, ensuring the production of high-quality ribbons within specification.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Inked Ribbons Quality Control Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Inked Ribbons Quality Control Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Inked Ribbons Quality Control Technicians play a crucial role in ensuring the quality and consistency of the inked ribbons used in various printing applications. Their primary responsibilities include:

1. Inspection and Testing

Conduct thorough visual and physical inspections of inked ribbons to verify their compliance with specified standards.

- Examine ribbons for defects, such as smudging, streaks, ink density, and color accuracy.

- Perform physical tests to measure ribbon thickness, width, and winding quality.

2. Data Analysis and Reporting

Collect and analyze data related to ribbon quality. Prepare reports summarizing inspection results and identifying any areas for improvement.

- Maintain records of inspections and test results.

- Identify trends and recommend corrective actions to enhance ribbon quality.

3. Equipment Maintenance and Calibration

Perform regular maintenance and calibration of testing equipment to ensure accurate and reliable results.

- Clean and adjust microscopes, densitometers, and other testing instruments.

- Collaborate with maintenance technicians to address equipment malfunctions.

4. Quality Assurance and Troubleshooting

Monitor the production process to identify potential quality issues. Provide guidance to production teams to resolve quality problems.

- Conduct root-cause analysis to determine the source of quality defects.

- Develop and implement corrective measures to prevent recurring quality issues.

Interview Tips

To ace an interview for an Inked Ribbons Quality Control Technician position, candidates should focus on showcasing their technical skills, attention to detail, and problem-solving abilities.

1. Highlight Your Technical Expertise

Demonstrate your proficiency in quality control techniques, such as visual inspection, physical testing, and data analysis. Quantify your experience with specific examples and results.

- “In my previous role, I implemented a new visual inspection method that reduced the rate of rejected ribbons by 15%.”

- “I developed a statistical analysis model to identify correlations between ribbon quality and production parameters, leading to a 10% improvement in overall ribbon quality.”

2. Emphasize Attention to Detail

Stress your ability to focus on minute details and ensure accuracy. Provide instances where your meticulous approach contributed to identifying and resolving quality issues.

- “During a visual inspection, I identified a subtle deviation in the ink density of a ribbon that led to its rejection and prevented a potential printing defect.”

- “By carefully examining equipment manuals, I discovered a minor calibration error that had caused a decrease in ribbon width, which I rectified promptly.”

3. Showcase Problem-Solving Skills

Convey your problem-solving abilities by describing situations where you identified, analyzed, and resolved quality issues. Highlight your critical thinking and decision-making skills.

- “I conducted a thorough investigation into a recurring issue of smudging ribbons. I identified a faulty feeder mechanism as the root cause and worked with the production team to implement a solution that eliminated the problem.”

- “When confronted with a new type of ribbon defect, I consulted with engineers and conducted experiments to determine the optimal solution, which resulted in a significant improvement in ribbon quality.”

4. Research the Company and Industry

Demonstrate your enthusiasm for the position by showing that you have researched the company and the industry. Prepare specific questions about the company’s quality control standards and processes.

- “I am particularly interested in your company’s commitment to ISO 9001 certification and how it has impacted your quality control practices.”

- “Can you elaborate on the industry trends that are shaping the demand for high-quality inked ribbons?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Inked Ribbons Quality Control Technician interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.