Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Inspector Machine Parts position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

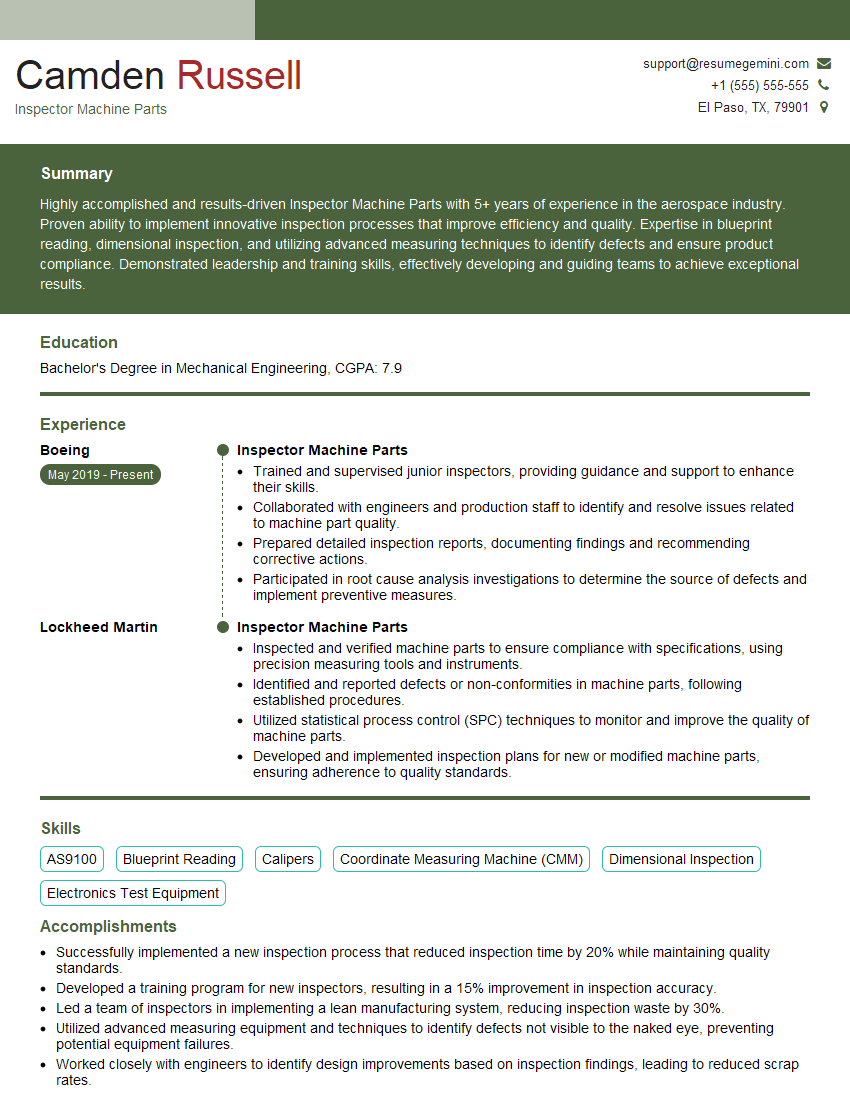

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Inspector Machine Parts

1. Describe the key responsibilities of an Inspector Machine Parts?

- Inspect manufactured machine parts to ensure adherence to specifications and quality standards.

- Measure and examine parts using precision instruments, such as calipers, micrometers, and coordinate measuring machines (CMMs).

- Verify dimensions, tolerances, surface finish, and other relevant characteristics against blueprints and technical drawings.

2. What are the crucial skills required for a successful Inspector Machine Parts?

- Excellent attention to detail and a keen eye for identifying defects and discrepancies.

- Proficiency in using measurement tools and inspection equipment, including calipers, micrometers, CMMs, and gauges.

- In-depth knowledge of mechanical engineering principles, tolerances, and quality control standards.

3. Describe the process of using a CMM to inspect a machine part.

- Secure the part on the CMM platform and align it with the reference system.

- Program the CMM with the inspection routine, including the measurement points and tolerance limits.

- Operate the CMM to collect measurement data, which is then analyzed using software to generate an inspection report.

4. What are the potential defects that you may encounter when inspecting machine parts?

- Dimensional deviations such as undersize, oversize, or out-of-tolerance conditions.

- Surface flaws such as scratches, dents, burrs, or corrosion.

- Material defects such as cracks, voids, or inclusions.

5. How do you ensure the accuracy and reliability of your inspection results?

- Regularly calibrate and maintain inspection equipment according to established standards.

- Follow standardized inspection procedures and document all inspection data.

- Undergo ongoing training to stay updated with the latest inspection techniques and industry best practices.

6. Describe your experience in using statistical process control (SPC) for quality improvement.

- Collecting and analyzing data on inspection results to identify trends and patterns.

- Developing control charts and other SPC tools to monitor and improve manufacturing processes.

- Collaborating with production and engineering teams to implement corrective actions and enhance quality.

7. How do you handle discrepancies and non-conforming parts?

- Report and document non-conforming parts immediately.

- Identify and investigate the root cause of the discrepancy.

- Suggest corrective actions to prevent similar defects from occurring in the future.

8. What are the latest industry trends and advancements in machine parts inspection?

- Integration of automated inspection systems, such as machine vision and laser scanning.

- Use of digital inspection tools and software for data analysis and reporting.

- Adoption of industry 4.0 technologies for real-time monitoring and quality control.

9. Describe your experience in working as part of a quality assurance team.

- Collaborating with other inspectors, engineers, and technicians to ensure adherence to quality standards.

- Participating in problem-solving and continuous improvement initiatives.

- Providing support and guidance to production staff on quality-related matters.

10. Why are you interested in this Inspector Machine Parts position with our company?

- Enthusiastic about the opportunity to contribute my skills and experience to your reputable organization.

- Interested in the company’s commitment to quality and innovation.

- Excited about the chance to work with a team of dedicated professionals in a challenging and rewarding environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Inspector Machine Parts.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Inspector Machine Parts‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Inspector Machine Parts is responsible for ensuring the quality of manufactured parts, ensuring they meet specifications and standards. Their duties involve various aspects of quality control, including:

1. Inspecting Machine Parts

Inspectors meticulously examine machine parts using various tools and techniques to verify their dimensions, tolerances, and surface finish.

- Measuring parts using precision instruments like calipers, micrometers, and coordinate measuring machines.

- Verifying part dimensions against blueprints and specifications to ensure accuracy.

- Inspecting parts for defects, such as scratches, burrs, or cracks, using visual or non-destructive testing methods.

2. Maintaining Quality Control Records

Inspectors maintain accurate records of their inspections, including:

- Documenting inspection results, including measurements, defects, and any deviations from specifications.

- Maintaining inspection logs and reports for future reference and analysis.

- Providing written or verbal reports to supervisors or clients on the quality of inspected parts.

3. Calibrating and Maintaining Inspection Equipment

Inspectors ensure the accuracy and reliability of inspection equipment, including:

- Calibrating measuring instruments regularly to ensure they meet industry standards.

- Maintaining inspection equipment in good working order through regular cleaning, maintenance, and repairs.

- Following established procedures for equipment use and calibration to ensure consistent and reliable measurements.

4. Providing Quality Feedback

Inspectors provide feedback to production staff on the quality of manufactured parts, including:

- Identifying areas where parts do not meet specifications or standards.

- Working with production staff to identify and resolve quality issues.

- Suggesting improvements to inspection processes or production methods to enhance quality.

Interview Tips

To prepare for an interview for an Inspector Machine Parts position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s industry, products, and quality standards.

- Visit the company’s website and review their mission statement, values, and recent news.

- Research the specific role and its responsibilities to understand the company’s expectations.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience in machine part inspection and quality control, including:

- Proficiency in using precision measuring instruments, such as calipers, micrometers, and CMMs.

- Knowledge of quality control standards and inspection techniques, such as ISO 9001 or AS9100.

- Experience in maintaining and calibrating inspection equipment.

3. Demonstrate Quality Consciousness

Convey your passion for quality and attention to detail.

- Share examples of your commitment to producing high-quality work.

- Explain how you ensure accuracy and reliability in your inspections.

4. Prepare for Technical Questions

Anticipate technical questions related to machine part inspection, such as:

- How do you measure the roundness of a part?

- What is the difference between a tolerance and a specification?

- How do you calibrate a micrometer?

5. Practice Your Communication Skills

Inspectors often need to communicate their findings clearly and effectively.

- Practice describing inspection results and explaining technical concepts to non-technical audiences.

- Prepare examples of how you have worked effectively with production staff to resolve quality issues.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Inspector Machine Parts interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!