Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Internal Combustion Engine Inspector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Internal Combustion Engine Inspector so you can tailor your answers to impress potential employers.

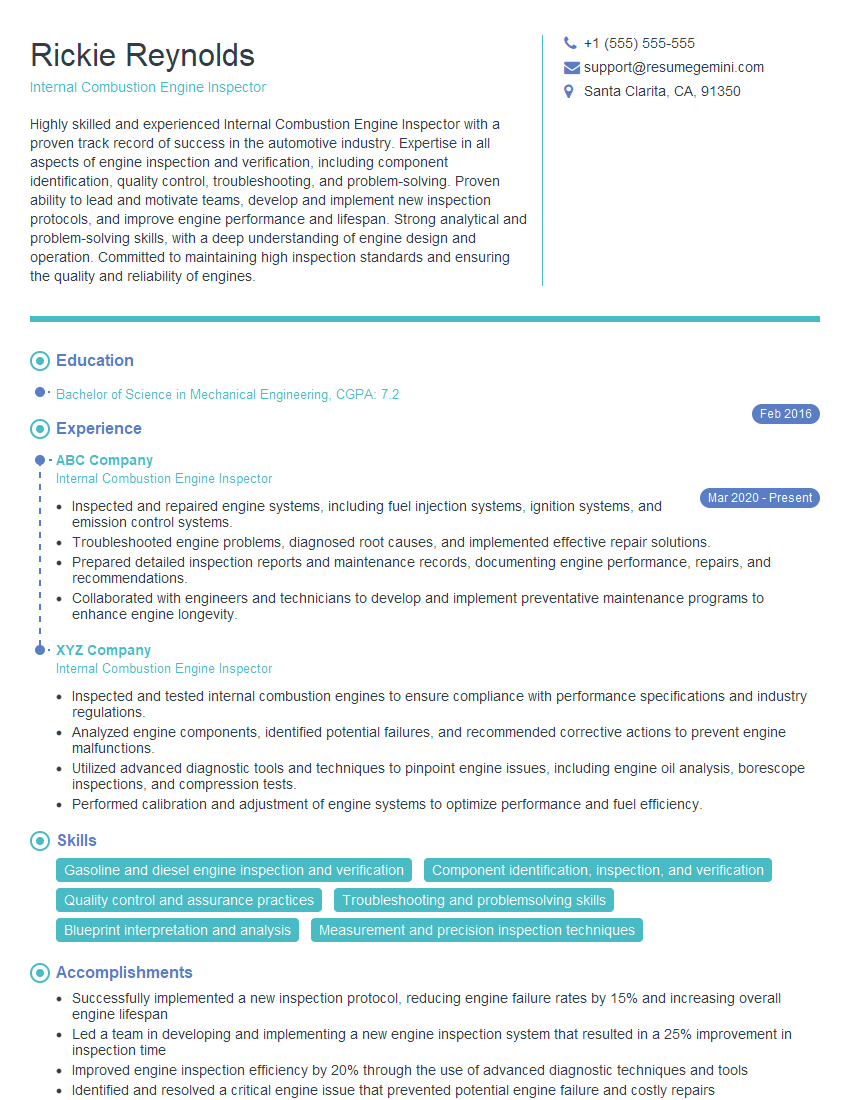

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Internal Combustion Engine Inspector

1. Describe the key components of an internal combustion engine and their functions?

An internal combustion engine consists of several key components, each playing a specific role in the engine’s operation. These components include:

- Cylinder: A cylindrical chamber where the combustion process occurs.

- Piston: A cylindrical-shaped component that moves up and down within the cylinder, compressing the air-fuel mixture and creating the necessary force for the engine to operate.

- Crankshaft: A rotating shaft that converts the reciprocating motion of the piston into rotational motion.

- Camshaft: A shaft that controls the timing of the engine’s valves, opening and closing them at the appropriate moments during the combustion cycle.

- Valves: Components that control the flow of air and fuel into and out of the cylinder.

- Spark plug (in gasoline engines) or injector (in diesel engines): Devices that ignite the air-fuel mixture or inject fuel into the cylinder.

- Cooling system: Components that dissipate heat generated by the engine, preventing overheating.

- Lubrication system: Components that provide lubrication to moving parts within the engine, reducing friction and wear.

2. Explain the four strokes of an internal combustion engine cycle?

Intake Stroke

- The intake valve opens, allowing air-fuel mixture to enter the cylinder.

- The piston moves down, creating a vacuum that draws the mixture into the cylinder.

Compression Stroke

- Both the intake and exhaust valves are closed.

- The piston moves up, compressing the air-fuel mixture, increasing its pressure and temperature.

Combustion Stroke (Power Stroke)

- The spark plug or injector fires, igniting the air-fuel mixture.

- The expanding gases drive the piston down, generating power.

Exhaust Stroke

- The exhaust valve opens.

- The piston moves up, pushing the exhaust gases out of the cylinder and through the exhaust valve.

3. Describe the different types of internal combustion engines?

- Gasoline engines: Spark-ignited engines that use gasoline as fuel.

- Diesel engines: Compression-ignition engines that use diesel fuel as fuel.

- Two-stroke engines: Engines that complete the combustion cycle in two piston strokes.

- Four-stroke engines: Engines that complete the combustion cycle in four piston strokes.

4. Explain the purpose and function of an engine management system?

An engine management system (EMS) is an electronic control system that optimizes the performance, efficiency, and emissions of an internal combustion engine. It monitors various engine parameters and adjusts the engine’s settings accordingly, including fuel injection, ignition timing, and valve timing. The EMS also plays a role in emission control, ensuring the engine meets regulatory standards.

5. Describe the methods used to diagnose and troubleshoot internal combustion engine problems?

- Visual inspection: Examining the engine for leaks, wear, or damage.

- Computer diagnostics: Using diagnostic tools to retrieve and analyze data from the engine’s sensors and control modules.

- Mechanical testing: Conducting tests to measure compression, vacuum, and other mechanical parameters.

- Electrical testing: Verifying the functionality of electrical components, such as sensors, actuators, and wiring.

6. Explain the importance of proper engine maintenance?

- Improved performance: Proper maintenance ensures the engine operates efficiently, maximizing power and fuel economy.

- Extended lifespan: Regular maintenance helps prevent premature wear and tear, prolonging the engine’s lifespan.

- Reduced emissions: A well-maintained engine produces fewer harmful emissions, benefiting the environment.

- Safety: Regular maintenance helps identify and address potential hazards, ensuring the engine operates safely.

7. Describe the different types of engine lubricants and their applications?

- Mineral oils: Petroleum-based lubricants that are suitable for general-purpose applications.

- Synthetic oils: Man-made lubricants that provide better protection and performance under extreme conditions.

- Semi-synthetic oils: Blends of mineral and synthetic oils that offer a balance of performance and cost.

- Specialty lubricants: Formulated for specific applications, such as high-performance engines or racing conditions.

8. Explain the purpose and function of an engine cooling system?

An engine cooling system prevents the engine from overheating by dissipating excess heat. It typically consists of a radiator, water pump, thermostat, and coolant. The coolant circulates through the engine, absorbing heat, and then flows through the radiator, where the heat is released into the surrounding air.

9. Describe the different types of engine sensors and their functions?

- Oxygen sensor: Measures the oxygen content in the exhaust gas, helping the engine management system adjust the air-fuel ratio.

- Knock sensor: Detects engine knocking and adjusts the ignition timing to prevent damage.

- Mass airflow sensor: Measures the mass of air entering the engine, helping the engine management system calculate the fuel injection quantity.

- Coolant temperature sensor: Monitors the engine coolant temperature and adjusts the cooling system accordingly.

10. Explain the importance of following safety precautions when working with internal combustion engines?

- Wear appropriate personal protective equipment: Safety glasses, gloves, and earplugs.

- Keep loose clothing and jewelry away from moving parts: Avoid entanglement and injury.

- Never start or run an engine in an enclosed space: Prevent carbon monoxide poisoning.

- Be aware of hot surfaces: Avoid burns and scalds.

- Disconnect the battery: Prevent electrical shock when performing maintenance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Internal Combustion Engine Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Internal Combustion Engine Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As an Internal Combustion Engine Inspector, you will be responsible for ensuring the quality and functionality of internal combustion engines. Some of your key responsibilities will include:

1. Inspection

Inspecting engines for defects, malfunctions, and compliance with specifications.

- Visually inspecting engines for any visible defects or damage.

- Using precision measuring tools to ensure that engine components meet specifications.

2. Testing

Performing tests to evaluate engine performance and identify any potential issues.

- Conducting compression tests to assess cylinder sealing and compression ratio.

- Performing leakdown tests to detect any air leaks in the engine.

3. Troubleshooting

Identifying and resolving issues with internal combustion engines.

- Diagnosing engine problems based on symptoms and test results.

- Determining the root cause of engine failures and recommending corrective actions.

4. Maintenance and Repair

Performing maintenance and repair tasks on internal combustion engines.

- Replacing worn or damaged engine components.

- Adjusting engine settings to optimize performance and efficiency.

Interview Tips

To help you ace your interview for an Internal Combustion Engine Inspector position, here are some tips and hacks:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the role. You can find this information on the company’s website, LinkedIn page, and other online resources.

- Make note of the company’s mission, vision, and values.

- Identify the key responsibilities and qualifications for the position.

2. Practice Your Answers

Once you have a good understanding of the company and the position, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview. Some common questions you may be asked include:

- Tell me about your experience as an Internal Combustion Engine Inspector.

- What are your strengths and weaknesses as an Internal Combustion Engine Inspector?

- Why are you interested in working for our company?

3. Dress Professionally

First impressions matter, so make sure to dress professionally for your interview. This means wearing a suit or business casual attire. You should also be well-groomed and have a clean and polished appearance.

- Choose clothing that is clean, pressed, and fits well.

- Avoid wearing clothing that is too revealing or too casual.

4. Be on Time

Punctuality is important, so make sure to arrive for your interview on time. If you are running late, be sure to call or email the interviewer to let them know.

- Plan your route ahead of time and leave yourself extra time for traffic or unexpected delays.

- If you are running late, call or email the interviewer as soon as possible to apologize and explain the situation.

5. Be Yourself

The most important thing is to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just be confident and genuine, and let your personality shine through.

- Answer questions honestly and authentically.

- Don’t be afraid to show your enthusiasm and passion for the role.

Next Step:

Now that you’re armed with the knowledge of Internal Combustion Engine Inspector interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Internal Combustion Engine Inspector positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini