Are you gearing up for an interview for a Jig Inspector position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Jig Inspector and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

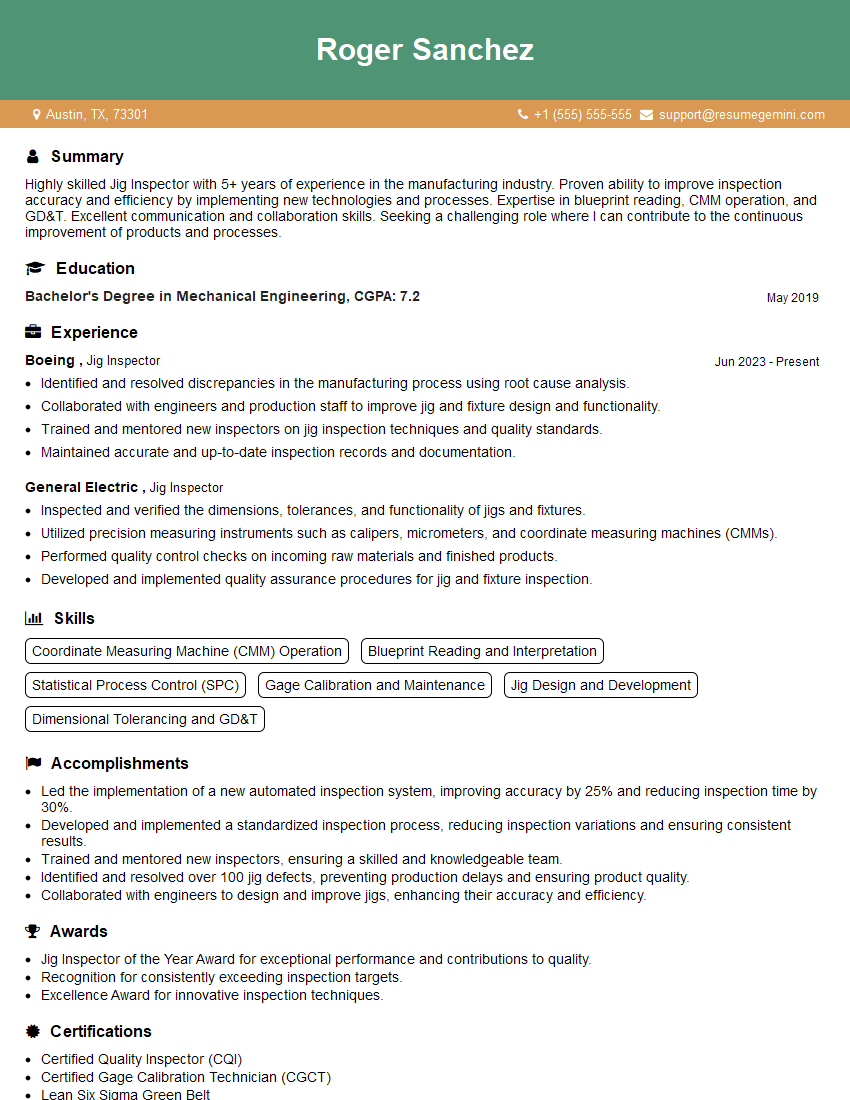

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Jig Inspector

1. What are the key responsibilities of a Jig Inspector?

As a Jig Inspector, my primary responsibilities include:

- Inspecting and testing jigs and fixtures to ensure they meet specifications and tolerances.

- Using precision measuring tools and gauges to verify dimensions, alignments, and surface finishes.

- Identifying and documenting any deviations or defects in jigs and fixtures.

- Maintaining inspection records and providing feedback to manufacturing teams.

- Collaborating with engineers and production staff to improve jig and fixture designs.

2. Can you describe the different types of jigs and fixtures you have experience with?

Types of Jigs

- Drill jigs

- Milling jigs

- Assembly jigs

- Welding jigs

Types of Fixtures

- Holding fixtures

- Locating fixtures

- Checking fixtures

- Assembly fixtures

3. What are the most common inspection methods used for jigs and fixtures?

The most common inspection methods include:

- Dimensional inspection: Using calipers, micrometers, and height gauges to measure dimensions.

- Alignment inspection: Using dial indicators and laser trackers to verify alignment.

- Surface finish inspection: Using surface roughness testers to measure surface smoothness.

- Hardness testing: Using Rockwell or Brinell hardness testers to assess material hardness.

4. What is the importance of maintaining accurate inspection records?

Accurate inspection records play a crucial role in:

- Documenting inspection results for traceability and audit purposes.

- Identifying trends and patterns in jig and fixture performance.

- Providing evidence of compliance with quality standards.

- Facilitating communication between inspection, manufacturing, and engineering teams.

5. How do you handle situations where a jig or fixture fails to meet specifications?

When a jig or fixture fails to meet specifications:

- Notify the appropriate personnel immediately.

- Document the deviation and identify its root cause.

- Suggest corrective actions to resolve the issue.

- Monitor the implementation of corrective actions to ensure effectiveness.

6. What is your experience with non-destructive testing methods?

I have experience with the following non-destructive testing methods:

- Ultrasonic testing: Using sound waves to detect internal defects.

- Dye penetrant testing: Using fluorescent dyes to reveal surface cracks.

- Magnetic particle testing: Using magnetic fields to detect surface and near-surface defects.

- Eddy current testing: Using electromagnetic fields to detect surface and subsurface defects.

7. How do you stay updated with the latest industry standards and best practices for jig and fixture inspection?

I stay updated through:

- Attending industry conferences and workshops.

- Reading technical journals and articles.

- Participating in online forums and discussion groups.

- Consulting with experts in the field.

8. What are the challenges you have faced in your previous role as a Jig Inspector?

One of the main challenges I faced was:

- Inspecting complex jigs and fixtures with tight tolerances.

- Troubleshooting and resolving issues with jigs and fixtures in a timely manner.

- Staying updated with the latest inspection technologies and best practices.

9. What is your understanding of the quality management system ISO 9001?

ISO 9001 is an international standard that specifies requirements for a quality management system. It focuses on:

- Establishing a systematic approach to quality management.

- Improving customer satisfaction through continuous improvement.

- Ensuring that products and services meet customer and regulatory requirements.

10. Can you provide an example of a time when you used your analytical skills to solve a problem with a jig or fixture?

In my previous role, I encountered a jig that was producing inconsistent results. I analyzed the inspection data and identified that the problem was caused by an error in the machining process. I recommended corrective actions to the manufacturing team, which resolved the issue and improved the jig’s performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Jig Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Jig Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Jig Inspector is primarily responsible for inspecting and ensuring the accuracy and functionality of jigs and fixtures used in manufacturing and assembly processes. Their key job responsibilities include:

1. Jig Inspection and Verification

Thoroughly inspect jigs and fixtures for dimensional accuracy, alignment, and functionality.

- Utilize precision measuring instruments (e.g., CMM, calipers, micrometers) to verify dimensions and tolerances.

- Ensure that jigs and fixtures meet design specifications and industry standards.

2. Quality Control and Reporting

Identify and document any defects or deviations from specifications.

- Prepare inspection reports and maintain records of inspection results.

- Collaborate with engineers and production staff to address quality issues and implement corrective actions.

3. Calibration and Maintenance

Calibrate and maintain measuring instruments used in inspection processes.

- Follow established calibration schedules and procedures.

- Identify and resolve any equipment malfunctions or calibration issues.

4. Process Optimization

Analyze inspection data and identify opportunities for process improvement.

- Develop and implement strategies to reduce inspection time and enhance accuracy.

- Provide feedback and suggestions to improve jig and fixture design and manufacturing.

Interview Tips

To prepare for a Jig Inspector interview, candidates should focus on showcasing their technical skills in inspection and quality control. They should also demonstrate their attention to detail and commitment to accuracy. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s industry, products, and quality standards. Research the specific job description to understand the key responsibilities and requirements.

- Visit the company’s website, LinkedIn page, and industry publications.

- Identify the specific industry standards and regulations applicable to the role.

2. Highlight Relevant Experience and Skills

Emphasize your experience in jig and fixture inspection, quality control, and measurement techniques. Quantify your accomplishments whenever possible.

- Discuss your proficiency in using precision measuring instruments, such as CMMs, calipers, and micrometers.

- Describe your experience in preparing inspection reports and documenting quality issues.

3. Showcase Attention to Detail

Provide examples of your meticulous approach to inspection and your ability to identify and resolve quality issues.

- Share stories of how you detected and corrected critical defects that could have impacted product quality.

- Discuss your strategies for ensuring accuracy and consistency in your inspection processes.

4. Emphasize Communication and Teamwork

Highlight your ability to communicate effectively with engineers, production staff, and other stakeholders.

- Describe your experience in collaborating to address quality concerns and implement corrective actions.

- Share examples of how you provided feedback and suggestions to improve jig and fixture design and manufacturing.

5. Prepare Questions to Ask

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement.

- Inquire about the company’s quality management system and industry certifications.

- Ask about the company’s plans for continuous improvement and process optimization.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Jig Inspector role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.