Are you gearing up for a career in Machine Shop Inspector? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Machine Shop Inspector and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

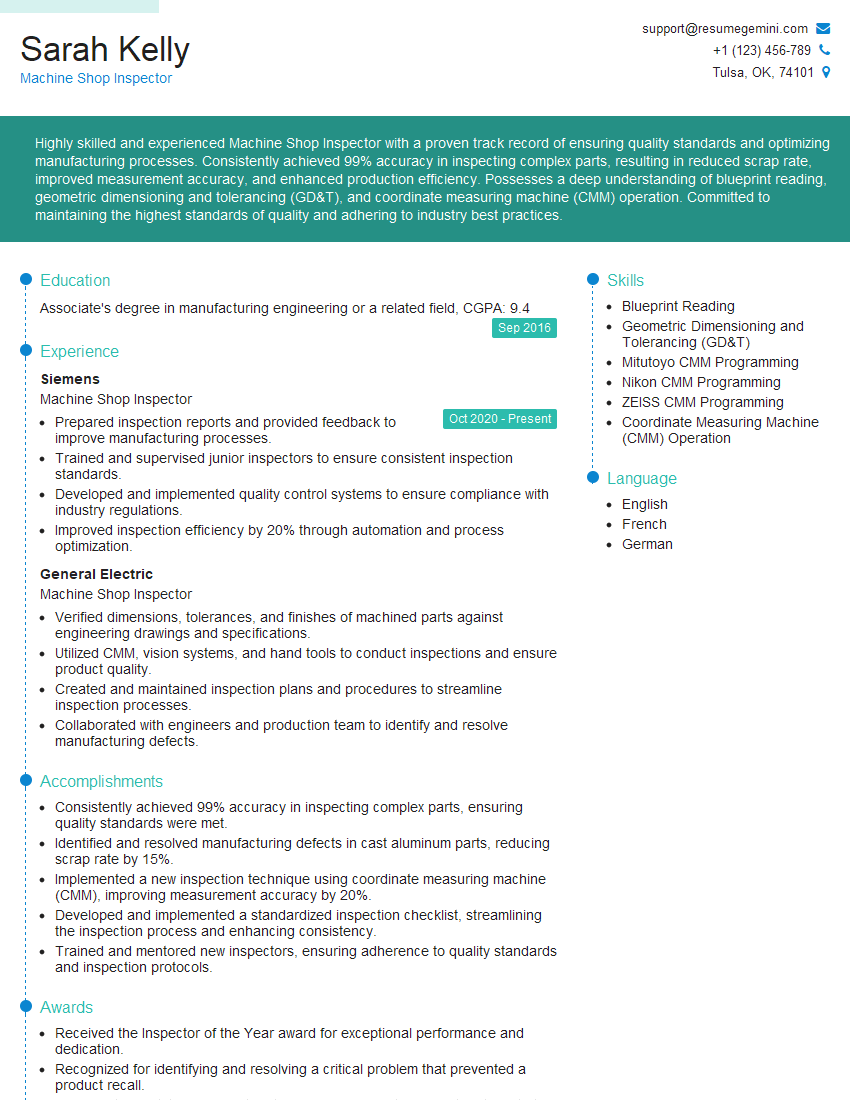

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Shop Inspector

1. What are the key responsibilities of a Machine Shop Inspector?

- Inspecting machined parts to ensure they meet specified tolerances and dimensions.

- Using measuring tools and instruments to verify part accuracy.

- Filing inspection reports and maintaining records of inspection results.

- Identifying and reporting defects or non-conformances.

- Ensuring that all inspected parts meet quality standards.

2. What types of measuring tools and instruments do you have experience using?

Types of Tools:

- Calipers

- Micrometers

- Gauges

- Optical comparators

- Coordinate measuring machines (CMMs)

Types of Instruments:

- Hardness testers

- Surface roughness testers

- Dimensional measuring systems

3. What are the most common defects you have encountered in machined parts?

- Dimensional errors (e.g., out-of-tolerance dimensions, burrs, nicks)

- Material flaws (e.g., cracks, inclusions, voids)

- Surface defects (e.g., scratches, pits, corrosion)

- Heat treatment issues (e.g., improper hardness, tempering)

- Machining errors (e.g., chatter marks, tool marks)

4. How do you determine the root cause of a defect?

The process of determining the root cause of a defect typically involves the following steps:

- Examine the part: Look for any visible defects or anomalies.

- Review the inspection report: Check the tolerances and specifications that the part was supposed to meet.

- Talk to the machinist: Get their input on the machining process and any potential issues that may have occurred.

- Inspect the tooling: Check for any wear or damage that could have caused the defect.

- Review the quality control process: Ensure that all necessary inspections and checks were performed.

5. What is your experience with using statistical process control (SPC)?

SPC is a powerful tool that can be used to improve the quality of machined parts. I have experience with using SPC in the following ways:

- Data collection: Collecting data on key quality characteristics, such as dimensions, surface roughness, and hardness.

- Data analysis: Using statistical methods to analyze the data and identify trends or patterns.

- Process improvement: Using the data to identify areas for improvement in the machining process.

6. What are your strengths and weaknesses as a Machine Shop Inspector?

Strengths:

- Strong attention to detail

- Excellent problem-solving skills

- Experience with a variety of measuring tools and instruments

- Knowledge of quality control principles and practices

Weaknesses:

- Lack of experience with certain specialized equipment

- Occasional difficulty working under tight deadlines

7. What are your career goals?

- To continue developing my skills and knowledge as a Machine Shop Inspector.

- To contribute to the success of my team and company.

- To eventually move into a management or supervisory role.

8. Why are you interested in this position?

- I am passionate about quality control and I am confident that I have the skills and experience necessary to be successful in this role.

- I am eager to learn new things and I am confident that I can make a valuable contribution to your team.

- I am excited about the opportunity to work in such a dynamic and challenging environment.

9. What is your salary expectation?

My salary expectations are commensurate with my experience and qualifications. I am confident that I can provide value to your company and I am willing to negotiate a salary that is fair and competitive.

10. Do you have any questions for me?

- I am very interested in the company’s commitment to quality control. Can you tell me more about the company’s quality control processes?

- I am eager to learn and develop my skills. Are there any opportunities for professional development within the company?

- I am a team player and I am always willing to go the extra mile. Can you tell me more about the company’s culture and values?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Shop Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Shop Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Shop Inspectors are quality control professionals who ensure that parts and products meet the required specifications. They play a critical role in maintaining high-quality standards and preventing defective products from reaching customers.

1. Inspecting Parts and Products

Inspectors use various tools and techniques to examine parts and products for defects, errors, and non-conformances. They may use micrometers, calipers, gauges, and other measuring instruments to ensure that dimensions and tolerances are within specifications.

2. Verifying Specifications

Inspectors compare parts and products against blueprints, drawings, and other technical specifications to ensure that they meet the required standards. They identify any deviations or discrepancies and report them to the appropriate personnel for corrective action.

3. Reporting and Documentation

Inspectors prepare inspection reports and maintain detailed records of their findings. They document any defects or non-conformances and provide recommendations for corrective action. They may also assist with the investigation of quality-related issues.

4. Calibrating Measuring Equipment

Inspectors regularly calibrate and maintain their measuring equipment to ensure accuracy and reliability. They follow established procedures and use certified calibration standards to ensure that their measurements are consistent and reliable.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your Machine Shop Inspector interview:

1. Research the Company and Role

Take the time to learn about the company, its products or services, and the specific role you are applying for. This will help you answer questions intelligently and show that you are genuinely interested in the position.

2. Practice Common Interview Questions

Prepare for common interview questions such as “Tell me about yourself,” “Why are you interested in this role,” and “What are your strengths and weaknesses.” Practice your answers and ensure that your responses are clear, concise, and highlight your relevant skills and experience.

3. Emphasize Your Inspection Skills

Highlight your experience and proficiency in using various inspection tools and techniques. Describe how you ensure accuracy and precision in your measurements and how you handle non-conforming parts or products.

4. Share Your Understanding of Quality Standards

Demonstrate your knowledge of quality standards such as ISO 9001 and AS9100. Explain how you apply these standards in your work and how you contribute to maintaining high-quality products.

5. Show Your Attention to Detail

Machine Shop Inspectors must have a keen eye for detail. In your interview, emphasize your ability to identify even the smallest defects or deviations. Provide examples of instances where you identified and resolved quality issues.

6. Be Prepared to Discuss Equipment Calibration

Inspectors are often responsible for calibrating measuring equipment. Be prepared to explain your understanding of calibration procedures and how you ensure the accuracy and reliability of your measurements.

7. Show Your Communication and Problem-Solving Skills

Machine Shop Inspectors need to be able to communicate effectively with other team members, vendors, and customers. Highlight your communication skills and provide examples of how you have resolved quality-related issues through effective communication and problem-solving.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Machine Shop Inspector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!