Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Manometer Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

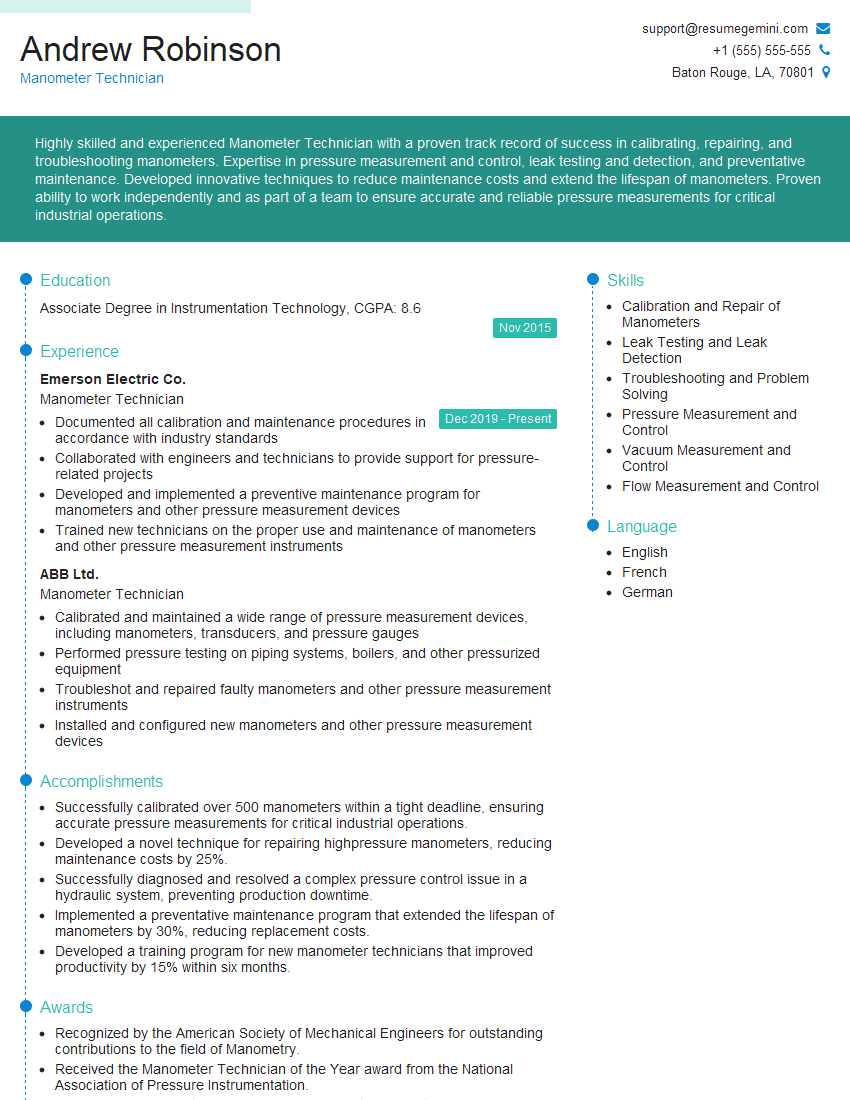

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Manometer Technician

1. What are the different types of manometers?

- Digital manometers: These manometers use a digital display to show the pressure reading.

- Analog manometers: These manometers use a dial and needle to show the pressure reading.

- Well-type manometers: These manometers are used to measure the pressure of liquids.

- Inclined-tube manometers: These manometers are used to measure the pressure of gases.

2. What are the factors that affect the accuracy of a manometer reading?

subheading of the answer

- The temperature of the fluid in the manometer.

- The density of the fluid in the manometer.

- The diameter of the manometer tube.

- The length of the manometer tube.

- The presence of air bubbles in the manometer tube.

subheading of the answer

- Calibration errors: Calibration is critical for ensuring accurate readings. If the manometer is not calibrated correctly, it can lead to incorrect measurements.

- Environmental factors: Temperature changes, vibrations, and shock can affect the manometer’s accuracy. It’s important to use the manometer in a stable environment to minimize these effects.

3. What are the safety precautions that should be taken when using a manometer?

- The manometer should be used in a well-ventilated area.

- The manometer should not be used to measure the pressure of flammable or explosive gases.

- The manometer should not be used to measure the pressure of liquids that are corrosive or toxic.

- The manometer should be inspected regularly for leaks.

4. What are the maintenance procedures that should be followed for a manometer?

- The manometer should be cleaned regularly.

- The manometer should be calibrated regularly.

- The manometer should be stored in a dry place.

5. What are the troubleshooting procedures that can be followed if a manometer is not working properly?

- Check the manometer for leaks.

- Check the manometer fluid level.

- Check the manometer calibration.

- If the manometer is still not working properly, it should be replaced.

6. What are the different applications of manometers?

- Measuring the pressure of liquids

- Measuring the pressure of gases

- Measuring the pressure of vacuum systems

- Measuring the pressure of hydraulic systems

- Measuring the pressure of pneumatic systems

7. What are the advantages of using a digital manometer over an analog manometer?

- Digital manometers are more accurate than analog manometers.

- Digital manometers are easier to read than analog manometers.

- Digital manometers can be used to measure a wider range of pressures than analog manometers.

- Digital manometers can be used to store and record data.

8. What are the disadvantages of using a digital manometer over an analog manometer?

- Digital manometers are more expensive than analog manometers.

- Digital manometers are more complex to use than analog manometers.

- Digital manometers are more susceptible to damage than analog manometers.

9. What are the different types of fluids that can be used in a manometer?

- Water

- Mercury

- Oil

- Glycerin

10. What is the difference between a gauge pressure and an absolute pressure?

- Gauge pressure is the pressure measured relative to atmospheric pressure.

- Absolute pressure is the pressure measured relative to a perfect vacuum.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Manometer Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Manometer Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Manometer Technicians are responsible for the installation, maintenance, and repair of manometers, which are devices used to measure pressure. They also calibrate and test manometers to ensure their accuracy.

1. Installation and Maintenance

Manometer Technicians typically work in industrial settings, such as factories and power plants. They are responsible for installing and maintaining manometers used to monitor pressure in various systems, such as hydraulics, pneumatics, and process control systems.

- Installing manometers according to specifications

- Performing regular maintenance on manometers, including cleaning, lubrication, and calibration

- Troubleshooting and repairing manometers

2. Calibration and Testing

Manometer Technicians also calibrate and test manometers to ensure their accuracy. This involves comparing the readings of the manometer to a known standard. If the readings are not within the acceptable range, the manometer must be adjusted or repaired.

- Calibrating manometers using reference pressure gauges or deadweight testers

- Conducting pressure tests to verify the accuracy of manometers

- Maintaining calibration records and providing certification

3. Troubleshooting and Repair

Manometer Technicians are also responsible for troubleshooting and repairing manometers. This involves identifying the problem and making the necessary repairs.

- Diagnosing problems with manometers

- Replacing faulty components, such as seals, diaphragms, and gauges

- Repairing leaks and other damages

4. Documentation and Reporting

Manometer Technicians are also responsible for documenting and reporting their work. This includes keeping records of all installations, maintenance, and repairs performed.

- Documenting all work performed on manometers

- Maintaining records of calibration and test results

- Reporting any problems or issues with manometers to supervisors

Interview Tips

Preparing for a job interview can be nerve-wracking, but there are a few things you can do to increase your chances of success.

1. Research the Company and the Position

Take some time to research the company you’re applying to and the specific position you’re interested in. This will help you understand the company’s culture and the skills and experience they’re looking for.

- Visit the company’s website

- Read articles about the company

- Talk to people who work at the company

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you can expect to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

- Use the STAR method to answer questions

- Be specific and provide examples

- Tailor your answers to the specific position you’re applying for

3. Dress Professionally and Arrive on Time

First impressions matter, so it’s important to dress professionally for your interview. You should also arrive on time, or even a few minutes early. This shows that you’re respectful of the interviewer’s time and that you’re serious about the position.

- Wear a suit or business casual attire

- Be well-groomed

- Arrive on time or early

4. Be Yourself and Be Enthusiastic

It’s important to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be enthusiastic about the position and the company, and let the interviewer know why you’re the best candidate for the job.

- Be genuine and authentic

- Show your enthusiasm for the position

- Explain why you’re the best candidate for the job

Next Step:

Now that you’re armed with the knowledge of Manometer Technician interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Manometer Technician positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini