Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Metal Control Worker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

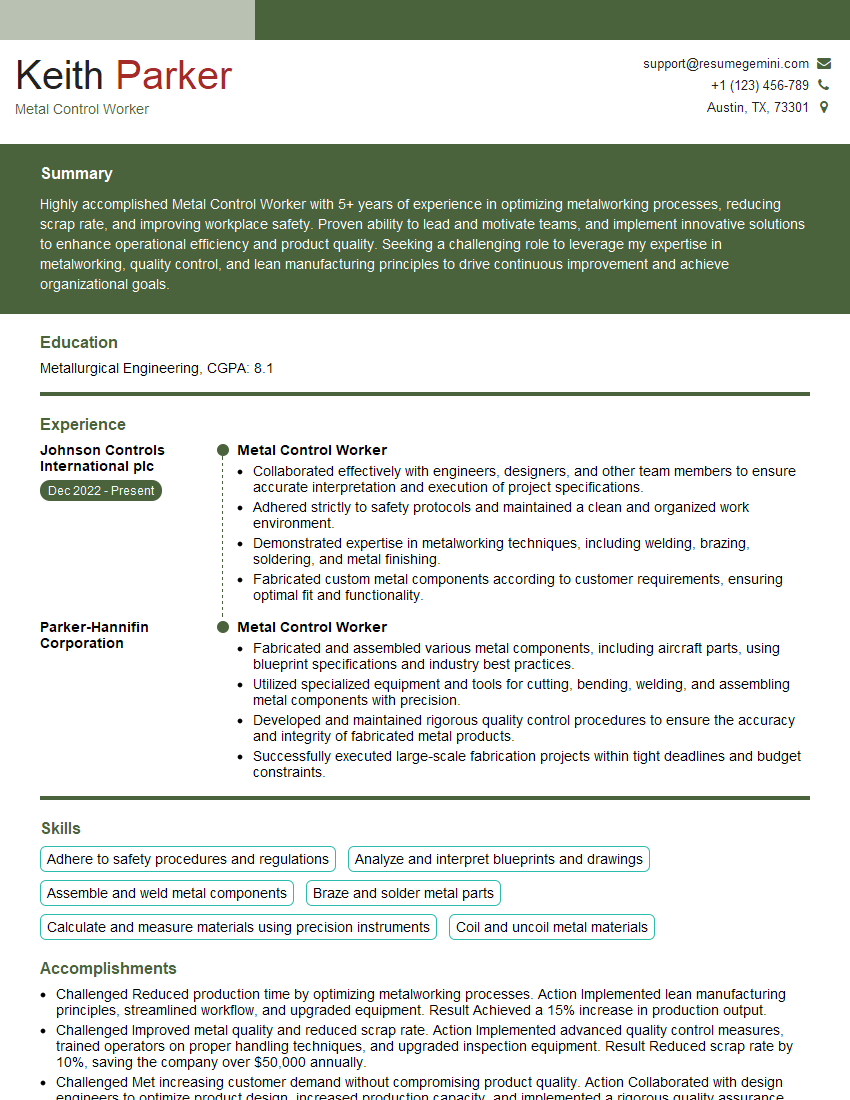

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Control Worker

1. Describe the process of heat treating metals?

Heat treating metals is a process that involves heating and cooling metal to alter its properties. It can be used to improve strength, hardness, toughness, and other desirable qualities. There are several different types of heat treatments, each with its own purpose and method.

- Annealing: This process involves heating the metal to a high temperature and then slowly cooling it. This results in a softer, more ductile metal.

- Normalizing: This process involves heating the metal to a high temperature and then cooling it in air. This results in a harder, stronger metal than annealing.

- Quenching: This process involves heating the metal to a high temperature and then rapidly cooling it in water or oil. This results in a very hard, brittle metal.

- Tempering: This process involves reheating the metal to a lower temperature after quenching. This helps to relieve some of the stresses introduced by quenching and improve toughness.

2. What are the different types of metalworking fluids?

Water-based fluids

- These fluids are made up of water and a variety of additives, such as rust inhibitors, lubricants, and surfactants.

- They are relatively inexpensive and easy to use.

- However, they can be corrosive to metals and can cause skin irritation.

Oil-based fluids

- These fluids are made up of petroleum oils and a variety of additives, such as anti-wear agents, extreme pressure additives, and corrosion inhibitors.

- They are more expensive than water-based fluids, but they offer better lubrication and corrosion protection.

- However, they can be difficult to remove from metal parts and can be a fire hazard.

Synthetic fluids

- These fluids are made up of synthetic hydrocarbons and a variety of additives, such as anti-wear agents, extreme pressure additives, and corrosion inhibitors.

- They offer the best performance of all types of metalworking fluids.

- However, they are also the most expensive.

3. What are the different types of metalworking machines?

- Lathes: These machines are used to rotate a workpiece while a cutting tool is fed into it. They can be used to create a variety of shapes, including cylinders, cones, and threads.

- Milling machines: These machines use a rotating cutter to remove material from a workpiece. They can be used to create a variety of shapes, including flat surfaces, slots, and gears.

- Drilling machines: These machines use a rotating drill bit to create holes in a workpiece. They can be used to create a variety of hole sizes and shapes.

- Grinding machines: These machines use a rotating abrasive wheel to remove material from a workpiece. They can be used to create a variety of surfaces, including flat surfaces, curved surfaces, and threads.

4. What are the different types of metalworking processes?

- Cutting: This process involves removing material from a workpiece using a cutting tool.

- Forming: This process involves changing the shape of a workpiece without removing any material.

- Joining: This process involves connecting two or more pieces of metal together.

- Finishing: This process involves improving the surface finish of a workpiece.

5. What are the different types of metalworking materials?

- Ferrous metals: These metals contain iron.

- Non-ferrous metals: These metals do not contain iron.

- Alloys: These metals are made up of two or more different elements.

6. What are the different types of metalworking safety hazards?

- Mechanical hazards: These hazards include moving machinery, sharp objects, and hot surfaces.

- Electrical hazards: These hazards include electrical shock and arc flash.

- Chemical hazards: These hazards include exposure to toxic chemicals and fumes.

- Ergonomic hazards: These hazards include repetitive motion injuries and musculoskeletal disorders.

7. What are the different types of metalworking quality control procedures?

- Visual inspection: This procedure involves looking at a workpiece to identify any defects.

- Dimensional inspection: This procedure involves measuring a workpiece to verify that it meets the required dimensions.

- Non-destructive testing: This procedure involves using non-destructive methods to identify defects in a workpiece.

- Destructive testing: This procedure involves destroying a workpiece to identify defects.

8. What are the different types of metalworking maintenance procedures?

- Preventive maintenance: This procedure involves performing regular maintenance tasks to prevent breakdowns.

- Corrective maintenance: This procedure involves repairing breakdowns.

- Predictive maintenance: This procedure involves using predictive maintenance techniques to identify potential breakdowns before they occur.

9. What are the different types of metalworking training programs?

- Apprenticeship programs: These programs combine on-the-job training with classroom instruction.

- Vocational training programs: These programs provide training in specific metalworking skills.

- College and university programs: These programs offer degrees in metalworking.

10. What are the different types of metalworking careers?

- Machinist: This career involves operating metalworking machines.

- Tool and die maker: This career involves making and repairing tools and dies.

- Welder: This career involves joining metals together.

- Metal fabricator: This career involves fabricating metal products.

- Quality control inspector: This career involves inspecting metal products to ensure that they meet quality standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Control Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Control Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Control Workers are responsible for ensuring the quality and accuracy of metal products. They work in a variety of settings, including factories, warehouses, and construction sites. Key job responsibilities include:

1. Inspecting metal products for defects

Metal Control Workers must be able to identify even the smallest defects in metal products. They use a variety of tools and techniques to check for cracks, corrosion, and other imperfections. They also make sure that the products meet all applicable specifications.

2. Measuring and cutting metal

Metal Control Workers must be able to accurately measure and cut metal. They use a variety of tools, including rulers, tape measures, and saws. They must also be able to interpret blueprints and follow instructions.

3. Assembling and welding metal components

Metal Control Workers may also be responsible for assembling and welding metal components. They must be able to follow instructions and work safely with welding equipment.

4. Maintaining metalworking equipment

Metal Control Workers must be able to maintain metalworking equipment. They must be able to identify and fix problems, and they must make sure that the equipment is safe to use.

Interview Tips

Preparing for an interview for a Metal Control Worker position can be intimidating, but the following tips can help you ace the interview and land the job.

1. Research the company

Before you go to your interview, take some time to research the company. This will help you understand the company’s culture and values, and it will also help you answer questions about the company’s products and services.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked. It is important to practice your answers to these questions so that you can answer them confidently and succinctly.

3. Be prepared to talk about your experience

The interviewer will want to know about your experience working with metal. Be sure to highlight your skills and abilities, and be prepared to provide examples of your work.

4. Be enthusiastic

Metal Control Workers are often passionate about their work. Show the interviewer that you are enthusiastic about the job and that you are excited to learn more about the company.

5. Be yourself

The most important thing is to be yourself. The interviewer will be able to tell if you are being fake, so just be yourself and let your personality shine through.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Control Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.