Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Molded Parts Inspector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Molded Parts Inspector so you can tailor your answers to impress potential employers.

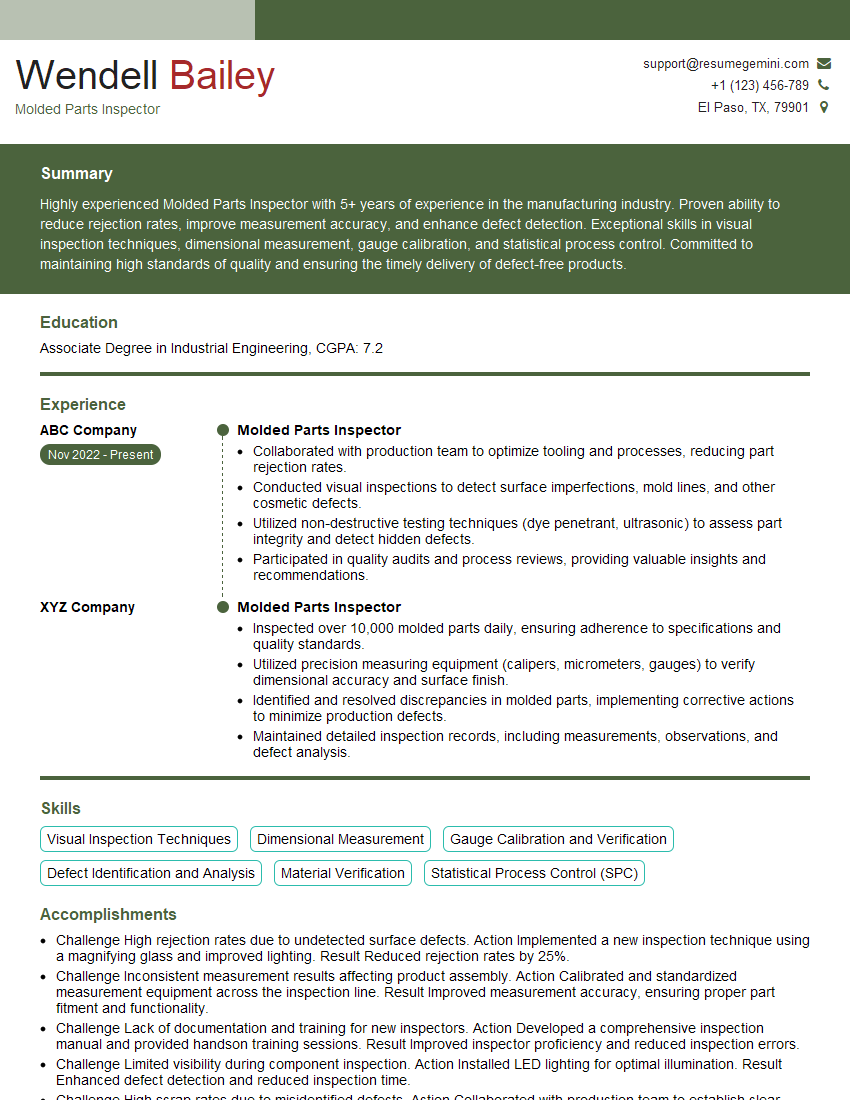

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Molded Parts Inspector

1. What are the key responsibilities of a Molded Parts Inspector?

As a Molded Parts Inspector, my primary responsibilities would include:

- Inspecting molded plastic parts for defects and dimensional accuracy using precision tools and gauges.

- Identifying and documenting any deviations from specifications, including scratches, cracks, voids, and discoloration.

2. Describe the inspection process you would follow to ensure the quality of molded parts.

- Visual Inspection: Examine the parts thoroughly for visible defects such as scratches, cracks, discoloration, and burrs.

- Dimensional Inspection: Measure the parts using calipers, micrometers, and other tools to ensure they meet specified dimensions and tolerances.

- Functional Inspection: Test the parts to ensure they meet functional requirements, such as fitment and performance.

3. Explain the different types of defects you may encounter during molded parts inspection and how you would handle them.

- Cosmetic Defects: Minor surface imperfections that do not affect part functionality, such as scratches or discoloration. These may be labeled for rework or rejected if excessive.

- Dimensional Defects: Deviations from specified dimensions, which may impact fitment or performance. These must be rejected or sent for rework.

- Structural Defects: Cracks, voids, or other damage that affects the part’s integrity. These are typically rejected and returned to the production line for correction.

4. What statistical process control techniques are you familiar with and how would you apply them to your role?

- Sampling Plans: Use sampling techniques to assess product quality and make decisions about acceptance or rejection of batches.

- Control Charts: Monitor inspection data to identify trends and process variations, allowing for proactive adjustments.

- Pareto Analysis: Analyze defect data to identify the most frequent and significant quality issues, enabling targeted improvement efforts.

5. Describe your experience with quality management systems, such as ISO 9001.

I have been involved in implementing and maintaining ISO 9001 systems in previous roles. My responsibilities included:

- Developing and documenting quality procedures and policies.

- Conducting internal audits to ensure compliance with the system.

- Monitoring and reporting on system effectiveness and recommending improvements.

6. What software or tools are you proficient in that are relevant to Molded Parts Inspection?

- Inspection Software: Specialized software for data collection, defect tracking, and reporting.

- Dimensional Inspection Tools: Calipers, micrometers, coordinate measuring machines (CMMs).

- Statistical Process Control Software: Tools for analyzing inspection data and creating control charts.

7. How would you ensure the accuracy and reliability of your inspections?

- Calibration: Regularly calibrate all inspection tools to maintain accuracy.

- Rigorous Inspection Process: Follow established inspection procedures and checklists to ensure consistency.

- Training and Development: Stay up to date with industry best practices and attend training programs to enhance inspection skills.

8. What is your understanding of the importance of communication in your role?

Effective communication is crucial for:

- Reporting Defects: Clearly communicating defect details to production to facilitate corrective actions.

- Collaboration with Quality Team: Working with the quality team to identify root causes of defects and implement solutions.

- Customer Relations: Maintaining strong relationships with customers by providing accurate inspection reports and responding promptly to inquiries.

9. Describe a situation where you identified a critical defect and took appropriate action.

During an inspection, I discovered a major dimensional discrepancy in a critical part that could have led to a serious safety hazard. I immediately:

- Isolated the defective parts to prevent their use.

- Notified the production team and quality department.

- Initiated an investigation to determine the root cause of the defect.

- Recommended corrective actions to prevent future occurrences.

10. Why are you interested in this Molded Parts Inspector position at our company?

- Your company’s reputation for producing high-quality molded parts.

- The opportunity to contribute my expertise to your quality control team.

- The company’s commitment to continuous improvement and innovation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Molded Parts Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Molded Parts Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Molded Parts Inspector is responsible for ensuring the quality of molded parts by conducting visual and dimensional inspections, as well as testing their mechanical properties. Their key job responsibilities include:

1. Visual Inspection

Inspecting molded parts visually for defects, such as cracks, scratches, surface imperfections, color variations, and missing or damaged components.

- Identifying and reporting any discrepancies between the molded parts and the approved specifications.

2. Dimensional Inspection

Using measuring instruments and equipment, such as calipers, micrometers, and coordinate measuring machines (CMMs), to measure the dimensions of molded parts and compare them to the specified tolerances.

- Analyzing the results of dimensional inspections and identifying any deviations that could affect the performance or fit of the molded parts.

3. Testing Mechanical Properties

Conducting tests to evaluate the mechanical properties of molded parts, such as tensile strength, flexural strength, and impact resistance, to ensure they meet the required specifications.

- Using appropriate testing equipment and following established procedures to obtain accurate and reliable test results.

4. Reporting and Documentation

Preparing and maintaining detailed inspection reports and documentation to record the results of inspections and tests.

- Communicating any non-conforming molded parts to the appropriate personnel and initiating corrective actions.

Interview Tips

To prepare for an interview for a Molded Parts Inspector position, it is important to have a clear understanding of the job responsibilities and the requirements outlined in the job posting. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to research the company and the specific Molded Parts Inspector position you are applying for. Understand the company’s products, services, and industry, as well as the specific responsibilities and qualifications required for the role.

- Visit the company’s website to gather information about their business, mission, and values.

- Read reviews and articles about the company to get an idea of their culture and reputation.

2. Highlight Relevant Skills and Experience

In your resume and during the interview, be sure to emphasize your skills and experience that are relevant to the Molded Parts Inspector role. This includes your experience in visual and dimensional inspections, testing mechanical properties, and reporting inspection results.

- Quantify your accomplishments with specific examples and metrics whenever possible.

- Tailor your resume and cover letter to highlight your most relevant skills and experience for the specific position you are applying for.

3. Prepare for Common Interview Questions

There are a number of common interview questions that you may be asked during an interview for a Molded Parts Inspector position. It is helpful to prepare for these questions by practicing your answers and tailoring them to the specific role and company you are interviewing with.

- Example Outline:

- Tell me about your experience in visual and dimensional inspections.

- Describe a time when you had to identify and resolve a non-conforming molded part.

- How do you stay up-to-date on the latest inspection techniques and standards?

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role. Some good questions to ask include:

- What are the biggest challenges facing the company or industry right now?

- What are the most important qualities you are looking for in a Molded Parts Inspector?

- What is the company’s culture like, and what are the values that are important to you?

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Molded Parts Inspector role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.