Are you gearing up for an interview for a Pressure Test Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Pressure Test Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

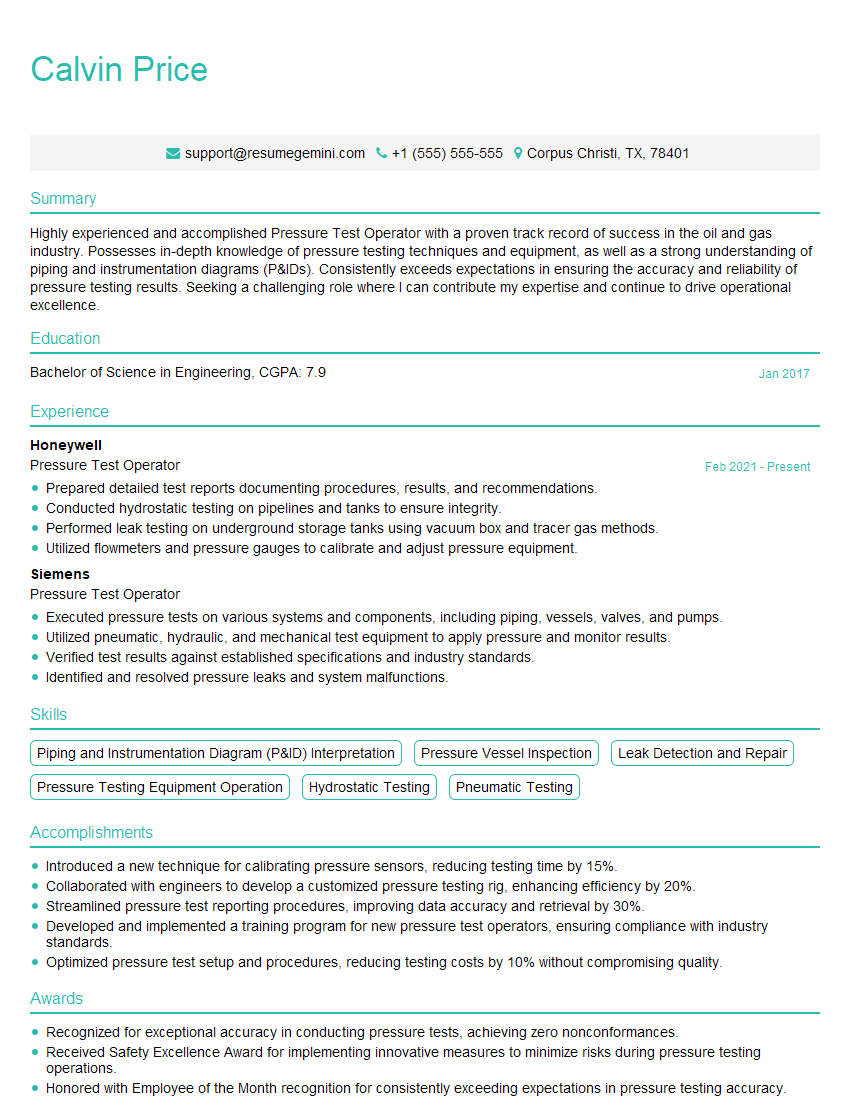

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pressure Test Operator

1. Explain the process of hydrostatic pressure testing?

Hydrostatic pressure testing involves filling a component or system with a liquid, typically water, and then applying pressure to the liquid to test the integrity of the component or system. The following steps summarize the process:

- Preparation: The component or system is prepared for testing by ensuring it is clean, free of leaks, and properly sealed.

- Filling: The component or system is filled with water or another suitable liquid.

- Pressurization: Pressure is gradually applied to the liquid using a pump or other pressurization device.

- Hold: The pressure is held at a specified level for a predetermined period to allow any leaks or weaknesses to develop.

- Examination: The component or system is carefully examined for leaks, deformation, or other signs of failure.

- Depressurization: The pressure is gradually released, and the liquid is drained from the component or system.

2. What are the different types of pressure tests that can be performed?

Destructive Testing

- Burst test: This test involves applying pressure until the component or system fails, allowing for the determination of its maximum pressure capacity.

- Proof test: This test applies a pressure higher than the normal operating pressure to verify the integrity of the component or system and identify any weaknesses.

Non-Destructive Testing

- Leak test: This test detects leaks by applying pressure and monitoring for any pressure loss or fluid leakage.

- Proof test: This test applies a pressure equal to or slightly higher than the normal operating pressure to ensure the component or system can withstand the expected operating conditions.

- Hydrostatic test: This test involves filling the component or system with water and applying pressure to test its integrity and identify any leaks or weaknesses.

3. What are the safety precautions that should be taken when performing pressure testing?

When conducting pressure testing, safety is paramount. Here are some crucial safety precautions to observe:

- Wear appropriate personal protective equipment, including gloves, safety glasses, and earplugs.

- Ensure the test area is well-ventilated and free from potential hazards.

- Use properly calibrated and maintained pressure gauges and equipment.

- Never exceed the specified pressure limits of the component or system being tested.

- Secure the component or system firmly to prevent movement or instability during testing.

- Have an emergency plan in place in case of equipment failure or unexpected events.

- Be aware of the potential for fluid leaks or bursts and take appropriate precautions.

- Follow established safety protocols and industry best practices.

4. What are the different methods used to measure pressure during pressure testing?

- Mechanical pressure gauges: These gauges use a Bourdon tube or diaphragm to indicate pressure mechanically.

- Electronic pressure gauges: These gauges use sensors to convert pressure into an electrical signal that is displayed digitally.

- Hydraulic pressure gauges: These gauges use a piston and cylinder arrangement to measure pressure by balancing it against a known force.

- Deadweight testers: These gauges use a series of precisely weighted weights to apply pressure and measure it accurately.

5. How do you interpret pressure test results?

Interpreting pressure test results involves analyzing the pressure readings and evaluating the component or system’s performance against established criteria. Here’s how to interpret the results:

- Pass: If the component or system holds pressure within the specified limits and does not exhibit any leaks or signs of failure, it passes the test.

- Fail: If the component or system fails to hold pressure, leaks, or shows signs of deformation or damage, it fails the test.

- Inconclusive: In some cases, the test results may be inconclusive, indicating the need for further investigation or retesting.

6. What are the common challenges faced during pressure testing?

- Equipment calibration: Ensuring that pressure gauges and equipment are properly calibrated is crucial for accurate testing.

- Leak detection: Identifying and locating leaks can be challenging, especially in complex systems.

- Component failure: Unexpected component failures during testing can occur due to various factors, such as material defects or design limitations.

- Safety concerns: Maintaining a safe testing environment and adhering to safety protocols is essential to prevent accidents.

7. How do you ensure the accuracy and reliability of pressure test results?

- Proper equipment: Use well-maintained and calibrated pressure gauges and equipment to ensure accurate readings.

- Controlled environment: Conduct tests in a controlled environment to minimize external factors that could affect results.

- Multiple tests: Perform multiple tests to verify the consistency of results and reduce the likelihood of false positives or negatives.

- Documentation: Keep detailed records of test procedures, results, and any deviations from standard protocols.

8. What is the importance of documentation in pressure testing?

Documentation is vital in pressure testing for several reasons:

- Quality control: Records provide evidence of the testing process, ensuring compliance with industry standards and regulations.

- Traceability: Documentation allows for traceability of test results to specific components or systems, aiding in failure analysis and quality improvement.

- Legal compliance: In certain industries, documentation is required for legal compliance and liability purposes.

- Knowledge sharing: Test results and documentation can be shared within the organization to improve knowledge and best practices.

9. How do you stay updated with the latest advancements in pressure testing techniques?

- Industry conferences: Attending conferences and seminars provides opportunities to learn about new technologies and best practices.

- Technical publications: Reading industry journals, white papers, and technical articles keeps me informed about advancements.

- Online resources: Websites, forums, and online training programs offer valuable information on emerging techniques.

- Networking: Connecting with other professionals in the field allows for the exchange of knowledge and insights.

10. What are the key qualities and skills required to be a successful Pressure Test Operator?

- Technical expertise: A strong understanding of pressure testing principles, equipment, and techniques.

- Attention to detail: Meticulous attention to detail is crucial for accurate test execution and interpretation of results.

- Safety consciousness: A high level of safety awareness and adherence to safety protocols is essential.

- Problem-solving skills: The ability to identify and resolve issues that arise during testing is crucial.

- Communication skills: Effective communication with colleagues, supervisors, and clients is important for clear reporting and documentation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pressure Test Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pressure Test Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pressure Test Operators perform comprehensive testing procedures on pressure vessels, pipelines, and other components to ensure their integrity and safety.

1. Conduct Pressure Tests

Execute pressure testing operations as per established protocols and standards.

- Apply hydrostatic, pneumatic, or vacuum pressure to test objects.

- Monitor pressure gauges, flow rates, and temperature during testing.

2. Analyze Test Results

Interpret test data and identify any anomalies or deviations from specifications.

- Calculate test results, including pressure ratings, leak rates, and burst pressures.

- Write detailed test reports and provide recommendations based on analysis.

3. Operate Testing Equipment

Utilize a variety of testing equipment, including pumps, pressure transducers, and data acquisition systems.

- Calibrate and maintain testing equipment to ensure accuracy and reliability.

- Follow safe operating procedures to prevent accidents or injuries.

4. Maintain Test Records

Document all test procedures, results, and observations for quality control and regulatory compliance.

- Maintain accurate and organized records of all pressure testing operations.

- Provide timely documentation to support quality assurance and regulatory requirements.

Interview Tips

Preparing thoroughly for a Pressure Test Operator interview can significantly increase your chances of success. Here are some valuable tips to help you ace the interview.

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry standing.

- Review the job description thoroughly to understand the specific requirements of the role.

- Research industry trends and best practices related to pressure testing.

2. Highlight Your Technical Skills

Emphasize your proficiency in pressure testing techniques, including hydrostatic, pneumatic, and vacuum testing.

- Quantify your experience with specific testing equipment and data analysis tools.

- Discuss your knowledge of pressure vessel design, materials properties, and safety regulations.

3. Demonstrate Attention to Detail

Pressure Test Operators must be meticulous and possess a keen eye for detail.

- Provide examples of your ability to follow complex testing procedures precisely.

- Highlight your experience in identifying and troubleshooting discrepancies in test results.

4. Emphasize Safety and Quality Assurance

Safety is paramount in pressure testing operations. Showcase your commitment to maintaining a safe work environment.

- Explain your adherence to established safety protocols and regulations.

- Describe your approach to ensuring the accuracy and reliability of test results.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Pressure Test Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Pressure Test Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.