Feeling lost in a sea of interview questions? Landed that dream interview for Production Grader but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Production Grader interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

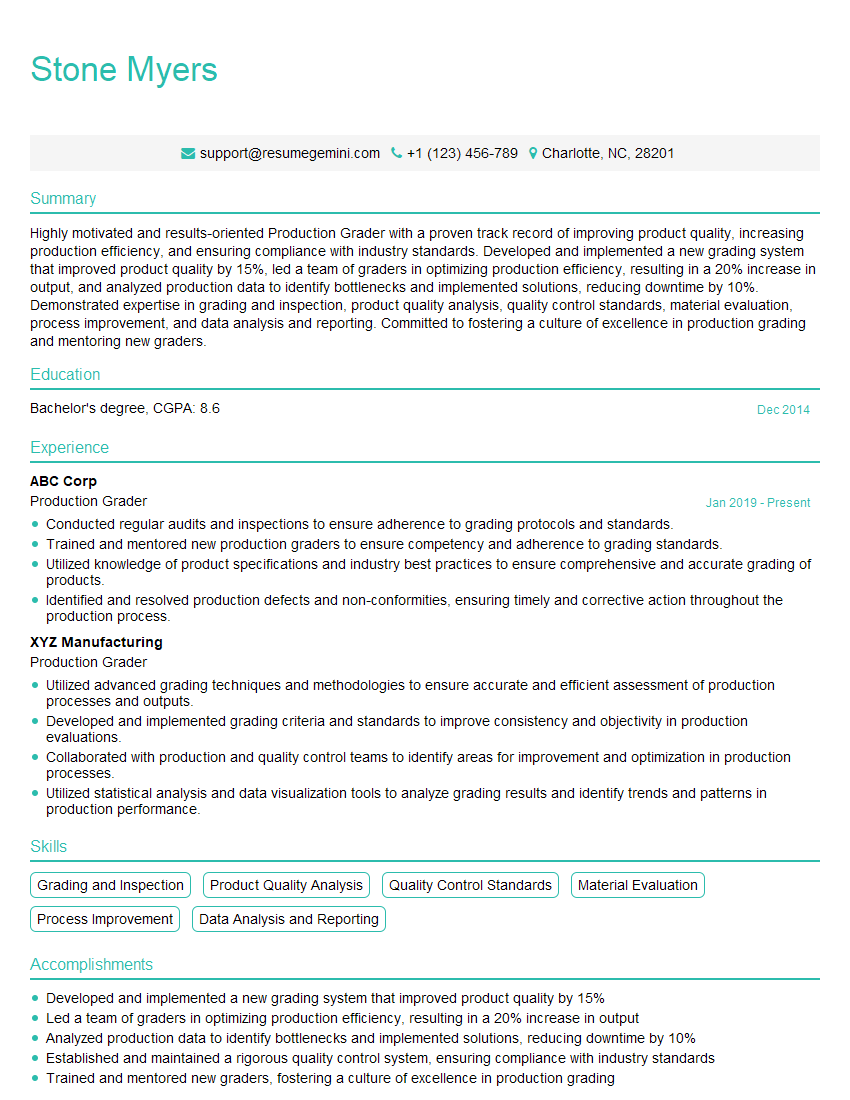

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Grader

1. How do you evaluate production data to identify areas for improvement?

– To evaluate production data for areas of improvement, I would start by gathering all relevant data from various sources such as production reports, machine logs, and quality control records. – I would then analyze the data to identify trends, patterns, and any potential bottlenecks or inefficiencies. – Furthermore, I would compare actual performance to established targets and industry benchmarks to identify any gaps and areas where improvements can be made.

2. What methods do you use to control and monitor production processes to ensure quality and efficiency?

Quality Control

- Implementing statistical process control techniques such as Six Sigma and Lean Manufacturing

- Conducting regular quality inspections and testing to identify and address defects

- Establishing and maintaining quality standards and procedures throughout the production process

Efficiency Monitoring

- Utilizing data analytics and production monitoring systems to track key performance indicators (KPIs) such as cycle time, throughput, and equipment effectiveness

- Conducting regular audits and reviews to identify areas for improvement and reduce waste

- Implementing continuous improvement initiatives to optimize processes and increase efficiency

3. How do you optimize production scheduling to maximize capacity utilization and meet customer demand?

– To optimize production scheduling, I would first analyze historical data and customer demand patterns to forecast future demand. – I would then develop a production schedule that balances capacity utilization with customer requirements, considering factors such as lead times, machine availability, and resource constraints. – I would also use scheduling software and techniques such as Gantt charts and critical path analysis to visualize and manage the schedule effectively.

4. What inventory management techniques do you use to minimize waste and ensure availability of raw materials and finished goods?

- Implementing inventory control systems such as Just-in-Time (JIT) and Kanban to reduce inventory levels and improve cash flow

- Using forecasting techniques to predict demand and optimize inventory replenishment

- Establishing safety stock levels to buffer against fluctuations in demand and supply

- Conducting regular inventory audits to identify and address discrepancies and improve accuracy

5. Describe your experience in implementing and managing lean manufacturing principles in a production environment.

– In my previous role, I successfully implemented lean manufacturing principles to improve production efficiency and reduce waste. – I identified and eliminated non-value-added activities through process mapping and value stream analysis. – I also introduced standardized work instructions, visual management techniques, and continuous improvement initiatives to empower employees and drive ongoing process optimization.

6. How do you collaborate with other departments, such as engineering, sales, and quality, to ensure a smooth production process?

– To ensure a smooth production process, I believe in fostering strong collaboration and communication with other departments. – I regularly engage with engineering to discuss product design and process improvements, ensuring that production requirements are met. – I also work closely with sales to understand customer demand and adjust production schedules accordingly. – Additionally, I maintain open communication with quality control to address any quality issues and ensure that products meet specifications.

7. What strategies do you use to motivate and engage production team members to achieve optimal performance?

- Setting clear performance expectations and providing regular feedback to employees

- Recognizing and rewarding employee achievements and contributions

- Creating a positive and empowering work environment that fosters teamwork and collaboration

- Encouraging employee involvement in process improvement initiatives and decision-making

- Providing opportunities for professional development and growth

8. Describe your experience in using data analysis and reporting tools to improve production processes.

– I am proficient in using data analysis tools such as Excel, Power BI, and SQL to extract insights from production data. – I have experience in creating reports and visualizations that communicate key performance indicators, trends, and areas for improvement. – By analyzing production data, I have identified bottlenecks, reduced cycle times, and optimized resource allocation, leading to increased productivity and efficiency.

9. What are the key safety protocols and regulations that you ensure are followed in the production environment?

- Enforcing the use of personal protective equipment (PPE) and adhering to established safety guidelines

- Conducting regular safety inspections and risk assessments to identify and mitigate potential hazards

- Providing safety training and education to production team members

- Establishing emergency response plans and procedures to ensure the safety of personnel and the facility

- Complying with all applicable industry regulations and standards, such as OSHA and ISO 9001

10. What are the latest trends and technologies in production management that you are familiar with?

– I stay updated with the latest trends and technologies in production management through industry publications, conferences, and online resources. – I am familiar with concepts such as Industry 4.0, automation, predictive analytics, and digital twins. – I believe that these technologies have the potential to revolutionize production processes and significantly enhance efficiency, quality, and customer satisfaction.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Grader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Grader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Production Grader is responsible for conducting tests and assessments on various products to determine their quality, performance, and safety. The key job responsibilities include:

1. Quality Control

Conducting various tests and inspections on materials, components, and finished products to ensure they meet established quality standards.

- Performing visual inspection, dimensional measurements, and other quality assurance checks.

- Using specialized equipment and tools to ensure accuracy and reliability.

2. Data Collection and Analysis

Collecting, analyzing, and interpreting data from tests and inspections to identify any discrepancies or defects.

- Preparing reports, charts, and other documentation to present findings.

- Collaborating with other team members to develop and implement corrective actions.

3. Process Improvement

Reviewing and evaluating processes to identify areas for improvement and efficiency.

- Suggesting and implementing changes to enhance quality and productivity.

- Monitoring and evaluating the effectiveness of implemented improvements.

4. Customer Service

Interacting with customers to understand their needs and provide technical support.

- Responding to customer inquiries and resolving any concerns.

- Providing guidance on product usage, maintenance, and troubleshooting.

Interview Tips

Preparing for a Production Grader interview requires a strong understanding of the job responsibilities and a well-crafted strategy. Here are some tips to help you ace the interview:

1. Research the Company and Position

Learn about the company’s history, values, and industry. Familiarize yourself with the specific job description and key responsibilities.

- Visit the company website, LinkedIn page, and industry publications.

- Review the job description thoroughly and highlight your skills and experience that align with the requirements.

2. Highlight Your Technical Skills

Emphasize your experience in conducting quality tests, analyzing data, and identifying defects. Showcase your proficiency in using specialized equipment and software.

- Provide specific examples of tests you have performed and how you interpreted the results.

- Quantify your accomplishments, using metrics to demonstrate your impact on quality improvement.

3. Demonstrate Your Problem-Solving Abilities

Production Graders often encounter challenges and need to develop creative solutions. Highlight your ability to think critically, identify root causes, and implement effective corrective actions.

- Share examples of how you have identified and resolved quality issues in previous roles.

- Explain how you collaborate with others to develop innovative solutions.

4. Emphasize Your Customer Service Orientation

Production Graders must be able to interact effectively with customers. Showcase your strong communication skills, empathy, and ability to provide technical support.

- Describe situations where you have successfully resolved customer complaints or provided guidance on product usage.

- Emphasize your ability to build rapport and maintain positive relationships with customers.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Production Grader interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.