Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pump Tester position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

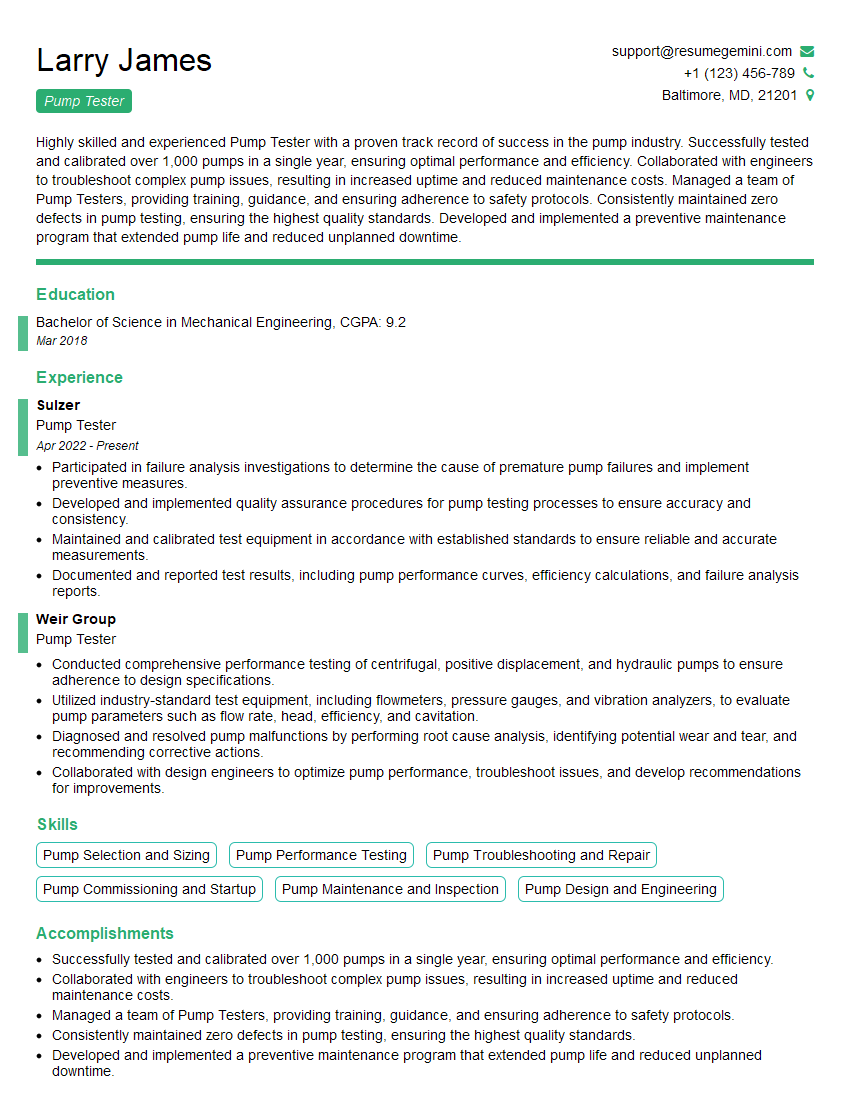

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pump Tester

1. What are the different types of pumps that you have experience working with?

- Centrifugal pumps

- Positive displacement pumps

- Axial flow pumps

- Mixed flow pumps

2. What are the key performance indicators (KPIs) that you use to measure the performance of a pump?

Flow rate

- The volume of fluid that passes through the pump per unit time.

- Measured in gallons per minute (GPM), cubic feet per second (CFS), or liters per second (L/s).

Head pressure

- The pressure difference between the inlet and outlet of the pump.

- Measured in feet of head, pounds per square inch (psi), or kilopascals (kPa).

Power consumption

- The amount of power required to operate the pump.

- Measured in kilowatts (kW) or horsepower (hp).

Efficiency

- The ratio of the power output to the power input.

- Expressed as a percentage.

3. What are the most common problems that you encounter when working with pumps?

- Pump cavitation

- Pump surging

- Pump vibration

- Pump leaks

- Pump failure

4. What are the steps that you take to troubleshoot a pump problem?

- Identify the symptoms of the problem.

- Check the pump for leaks, vibration, or noise.

- Measure the flow rate, head pressure, and power consumption of the pump.

- Inspect the pump for any damage.

- Consult the pump manufacturer’s documentation.

- Replace any damaged parts.

- Retest the pump to ensure that it is operating properly.

5. What are the different types of pump seals that you have experience with?

- Mechanical seals

- Gland packing

- Lip seals

- O-rings

6. What are the advantages and disadvantages of different types of pump seals?

Mechanical seals

Advantages

- Low friction

- Long lifespan

- Good sealing ability

Disadvantages

- Expensive

- Can be difficult to install

Gland packing

Advantages

- Inexpensive

- Easy to install

- Can be used in a wide range of applications

Disadvantages

- High friction

- Short lifespan

- Poor sealing ability

Lip seals

Advantages

- Low friction

- Long lifespan

- Good sealing ability

Disadvantages

- Can be damaged by abrasive fluids

- Can be difficult to install

O-rings

Advantages

- Inexpensive

- Easy to install

- Good sealing ability

Disadvantages

- Can be damaged by high temperatures or pressures

- Can be difficult to use in applications with a lot of vibration

7. What are the different types of pump bearings that you have experience with?

- Ball bearings

- Roller bearings

- Sleeve bearings

- Hydrodynamic bearings

8. What are the advantages and disadvantages of different types of pump bearings?

Ball bearings

Advantages

- Low friction

- Long lifespan

- Good load capacity

Disadvantages

- Can be noisy

- Can be damaged by shock loads

Roller bearings

Advantages

- Low friction

- Long lifespan

- High load capacity

Disadvantages

- Can be noisy

- Can be damaged by shock loads

Sleeve bearings

Advantages

- Low friction

- Long lifespan

- Quiet operation

Disadvantages

- Low load capacity

- Can be damaged by shock loads

Hydrodynamic bearings

Advantages

- Very low friction

- Very long lifespan

- Quiet operation

Disadvantages

- Very expensive

- Can be difficult to design and manufacture

9. What are the different types of pump couplings that you have experience with?

- Flexible couplings

- Rigid couplings

- Combination couplings

10. What are the advantages and disadvantages of different types of pump couplings?

Flexible couplings

Advantages

- Absorb shock and vibration

- Accommodate misalignment

- Easy to install and maintain

Disadvantages

- Can be less efficient than rigid couplings

- Can be more expensive than rigid couplings

Rigid couplings

Advantages

- More efficient than flexible couplings

- Less expensive than flexible couplings

- Easier to design and manufacture

Disadvantages

- Do not absorb shock and vibration

- Do not accommodate misalignment

- Can be more difficult to install and maintain

Combination couplings

Advantages

- Combine the advantages of both flexible and rigid couplings

- Absorb shock and vibration while still being efficient

- Accommodate misalignment while still being easy to install and maintain

Disadvantages

- Can be more expensive than either flexible or rigid couplings

- Can be more difficult to design and manufacture

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pump Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pump Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pump Testers are responsible for ensuring the proper functioning and efficiency of pumps in various settings.

1. Pump Testing and Evaluation

Conduct thorough tests on pumps to evaluate their performance, efficiency, and reliability.

- Measure pump flow rates, pressures, and power consumption.

- Analyze test data and identify potential issues or areas for improvement.

2. Maintenance and Troubleshooting

Perform routine maintenance and troubleshooting on pumps to prevent breakdowns and ensure optimal operation.

- Replace worn or damaged parts, such as impellers, seals, and bearings.

- Diagnose pump failures and implement corrective actions.

3. Data Analysis and Reporting

Analyze and interpret test results and generate detailed reports on pump performance.

- Identify trends and make recommendations for optimizing pump efficiency.

- Communicate results to stakeholders, including engineers, maintenance personnel, and management.

4. Collaboration and Communication

Collaborate with other team members, engineers, and contractors to ensure smooth project execution.

- Participate in design reviews and troubleshooting sessions.

- Provide technical guidance and support to colleagues and clients.

Interview Tips

Preparing for a Pump Tester interview requires thorough research and practice.

1. Research the Company and Role

Familiarize yourself with the company’s products, services, and industry. Understand the specific responsibilities and requirements of the Pump Tester role.

2. Highlight Your Technical Skills

Showcase your proficiency in pump testing, maintenance, and troubleshooting techniques. Emphasize your experience with industry-standard equipment and software.

3. Demonstrate Your Problem-Solving Abilities

Discuss your approach to problem-solving and how you have successfully resolved pump-related issues in the past. Provide specific examples and results.

4. Prepare for Common Interview Questions

Practice answering common interview questions relevant to Pump Testing, such as:

- Can you describe your experience in evaluating pump performance?

- How do you troubleshoot and repair pump failures?

- What are the key performance indicators you use to measure pump efficiency?

- How do you ensure data accuracy and integrity in your pump testing?

5. Prepare Questions for the Interviewer

This shows your interest and engagement. Ask thoughtful questions about the company, the role, or the industry.

6. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately and arrive on time for the interview. Be polite and respectful to the interviewer and other staff you encounter.

7. Follow Up

After the interview, send a thank-you note to the interviewer. Reiterate your interest in the role and highlight your key qualifications.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pump Tester interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.