Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Railroad Wheels and Axles Inspector position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

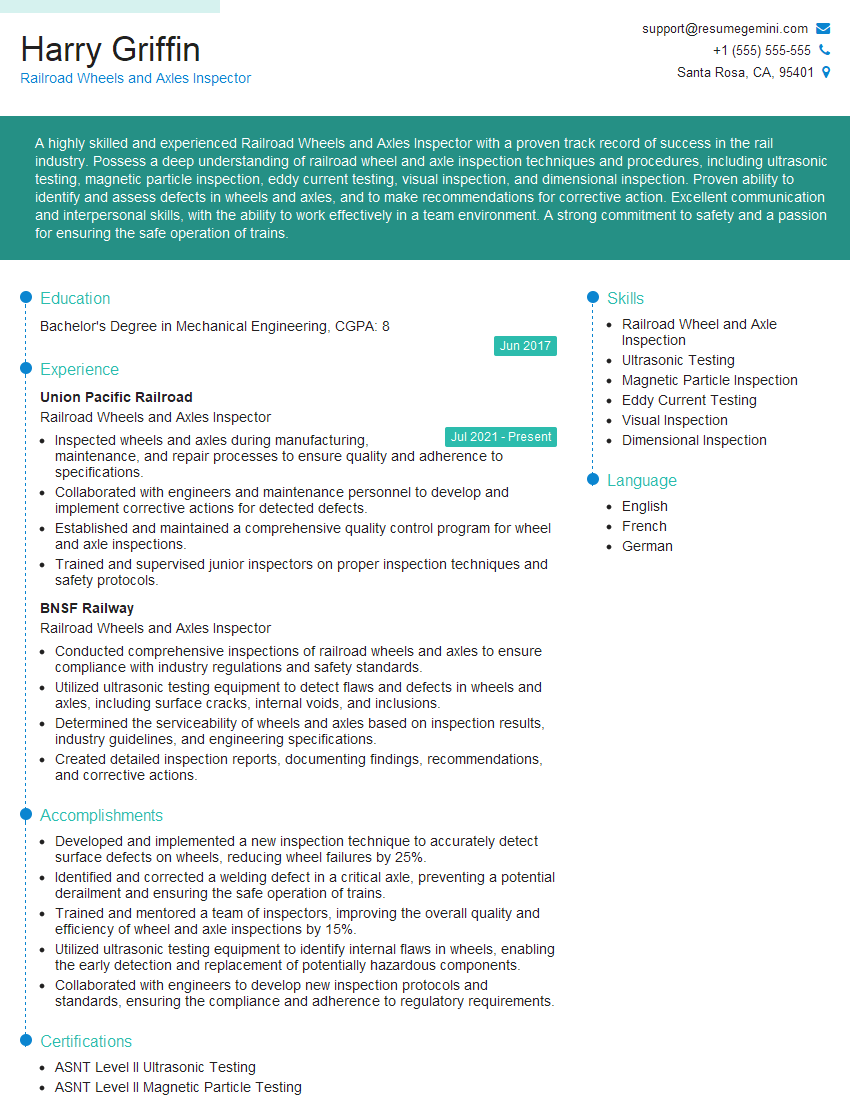

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Railroad Wheels and Axles Inspector

1. Explain the importance of properly inspecting railroad wheels and axles?

Regularly inspecting railroad wheels and axles is critical for ensuring the safety and reliability of railway operations. Wheels and axles are essential components that bear the weight of the train and guide it along the tracks. Proper inspection allows us to detect defects, such as cracks, wear, or damage, which can lead to catastrophic failures if left unattended.

By identifying potential issues early on, we can take proactive measures to prevent accidents, minimize downtime, and maintain the integrity of the railroad system. Neglecting proper inspection can result in derailments, injuries to passengers or crew, and significant financial losses.

2. Describe the different types of defects you inspect railroad wheels for.

When inspecting railroad wheels, I look for a wide range of defects that could compromise their safety and performance. These include:

- Cracks: Cracks in the wheel can weaken its structure, potentially leading to catastrophic failure.

- Flat spots: Flat spots on the wheel can cause vibration and instability, affecting the train’s ride quality and potentially damaging the track.

- Wear: Excessive wear can reduce wheel diameter, affecting braking efficiency and leading to uneven wear on the track.

- Thermal damage: Overheating can cause thermal damage to the wheel, altering its properties and reducing its strength.

- Improper contour: Deviations from the specified wheel profile can affect the train’s stability and handling characteristics.

3. What non-destructive testing (NDT) methods do you use to inspect railroad axles?

To thoroughly inspect railroad axles, I employ a combination of non-destructive testing (NDT) methods, including:

- Ultrasonic testing (UT): This technique uses high-frequency sound waves to detect internal flaws, such as cracks or voids.

- Magnetic particle testing (MT): This method utilizes magnetic fields and iron particles to identify surface-breaking cracks.

- Eddy current testing (ET): This technique employs electromagnetic fields to detect surface and near-surface defects, including cracks and corrosion.

- Dye penetrant testing (PT): This method involves applying a dye to the axle’s surface to reveal surface-breaking cracks or porosity.

4. How do you determine the severity of a defect you find during an inspection?

When I discover a defect during an inspection, I assess its severity based on several factors, including:

- Size and location of the defect: Larger defects or those located in critical areas pose a greater risk.

- Type of defect: Certain defects, such as cracks or internal voids, are more serious than others.

- Material of the wheel or axle: Different materials have varying tolerances for defects.

- Operating conditions: I consider the intended use and loading conditions of the wheel or axle.

Based on this evaluation, I assign a severity level to the defect and determine whether it requires immediate repair, further monitoring, or replacement.

5. What documentation do you generate after completing an inspection?

After completing an inspection, I generate a detailed report that includes the following:

- Identification of the inspected wheel or axle, including its location on the train.

- A description of the inspection method(s) used.

- A record of all defects discovered, including their size, location, and severity.

- Recommendations for repair or replacement, if necessary.

- The date and time of the inspection.

- My signature and certification as a qualified inspector.

This report provides a comprehensive record of the inspection and serves as documentation for maintenance and safety purposes.

6. How do you stay up-to-date on the latest industry standards and best practices for railroad wheel and axle inspection?

To ensure that my inspection practices meet the highest standards, I actively engage in ongoing professional development and training.

- I regularly attend industry conferences, workshops, and seminars to learn about new technologies, inspection techniques, and regulatory updates.

- I am an active member of professional organizations, such as the American Society for Nondestructive Testing (ASNT), where I have access to technical resources and networking opportunities.

- I subscribe to industry publications and journals to stay informed about the latest research and developments in my field.

- I am committed to continuous learning and improvement, ensuring that I am always up-to-date with the latest industry best practices.

7. What are the safety precautions you take when inspecting railroad wheels and axles?

Safety is paramount in all aspects of my inspection work. I adhere to strict safety protocols and procedures to minimize risks:

- I wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a hard hat.

- I ensure that the inspection area is well-lit and free of hazards.

- I follow proper lifting techniques and use lifting equipment when necessary.

- I am aware of the location of emergency exits and equipment.

- I communicate any potential hazards to colleagues and supervisors.

By prioritizing safety, I create a controlled and risk-free environment for myself and those around me.

8. How do you handle situations where you encounter conflicting interpretations of inspection results?

In cases where there are differing interpretations of inspection results, I follow a collaborative and methodical approach to resolve the issue:

- I consult with senior inspectors or specialists to seek their expertise and insights.

- I review relevant industry standards and guidelines to ensure that my interpretation is accurate.

- I engage in open and respectful discussions with colleagues to exchange perspectives and reach a consensus.

- I am willing to adjust my interpretation based on sound technical evidence and reasoning.

- Ultimately, I prioritize safety and make decisions that are in the best interest of maintaining the integrity of the railroad system.

9. Describe a complex or challenging inspection you performed and how you resolved it.

During a recent inspection, I encountered a complex defect in a railroad axle. The defect was not readily apparent and required a combination of NDT techniques to identify and assess its severity.

Using a combination of ultrasonic testing and magnetic particle testing, I was able to determine that the defect was a subsurface crack that extended deep into the axle’s core.

To resolve the issue, I consulted with a senior inspector and an engineering specialist. Together, we determined that the axle needed to be replaced immediately to avoid a potential catastrophic failure.

The successful resolution of this complex inspection demonstrates my ability to identify and address challenging defects, ensuring the safety and reliability of the railroad system.

10. What qualities make you a successful Railroad Wheels and Axles Inspector?

As a highly qualified Railroad Wheels and Axles Inspector, I possess the following qualities that contribute to my success:

- Attention to Detail: I am meticulous and thorough in my inspections, ensuring that every aspect of the wheels and axles is carefully examined.

- Technical Expertise: I have a deep understanding of the materials, manufacturing processes, and inspection techniques used in the railroad industry.

- Problem-Solving Skills: I am adept at identifying and resolving complex issues related to wheel and axle integrity.

- Safety Consciousness: Safety is my top priority, and I adhere to all established safety protocols and procedures.

- Communication Skills: I am effective in communicating my findings, recommendations, and technical insights to supervisors, colleagues, and clients.

My combination of skills and experience enables me to consistently deliver high-quality inspections, ensuring the safety and reliability of railroad operations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Railroad Wheels and Axles Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Railroad Wheels and Axles Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Railroad Wheels and Axles Inspectors are responsible for ensuring that wheels and axles on railroad cars meet safety standards. They inspect wheels for cracks, wear, and other defects. They also inspect axles for cracks, bends, and other damage. Inspectors must be able to identify and measure defects according to established standards. They must also be able to interpret inspection results and make decisions about whether wheels and axles are safe to use.

1. Inspect wheels and axles for defects

Inspectors use a variety of tools to inspect wheels and axles. These tools include ultrasonic testing equipment, magnetic particle testing equipment, and eddy current testing equipment. Inspectors must be able to use these tools safely and effectively. They must also be able to interpret the results of inspections and make decisions about whether wheels and axles are safe to use.

2. Measure defects

Inspectors must be able to measure defects accurately. They use a variety of measuring tools, including calipers, micrometers, and gauges. Inspectors must be able to use these tools safely and accurately. They must also be able to record measurements accurately.

3. Interpret inspection results

Inspectors must be able to interpret the results of inspections and make decisions about whether wheels and axles are safe to use. They must be able to identify and measure defects according to established standards. They must also be able to assess the severity of defects and make decisions about whether wheels and axles can be repaired or must be replaced.

4. Report inspection results

Inspectors must be able to report inspection results clearly and concisely. They must be able to write reports that are easy to understand and that provide all of the necessary information. Inspectors must also be able to communicate verbally with supervisors, other inspectors, and railroad personnel.

Interview Tips

Preparing for an interview for a Railroad Wheels and Axles Inspector position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the company and the position

Take the time to learn about the company and the specific position you are applying for. This will help you understand the company’s culture and the expectations of the role. You can research the company’s website, read industry news articles, and talk to people in your network who work for the company.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked. Practice answering these questions in advance so that you can deliver your answers confidently and concisely. Some common interview questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with railroad inspection?

- What are your salary expectations?

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

4. Be prepared to talk about your experience and qualifications

The interviewer will want to know about your experience and qualifications. Be prepared to talk about your skills, knowledge, and experience in railroad inspection. You should also be prepared to provide examples of your work.

5. Ask questions

Asking questions shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the role. Some good questions to ask include:

- What are the biggest challenges facing the company?

- What are the company’s long-term goals?

- What is the company’s culture like?

- What are the opportunities for advancement?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Railroad Wheels and Axles Inspector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!