Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Raw Silk Grader interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Raw Silk Grader so you can tailor your answers to impress potential employers.

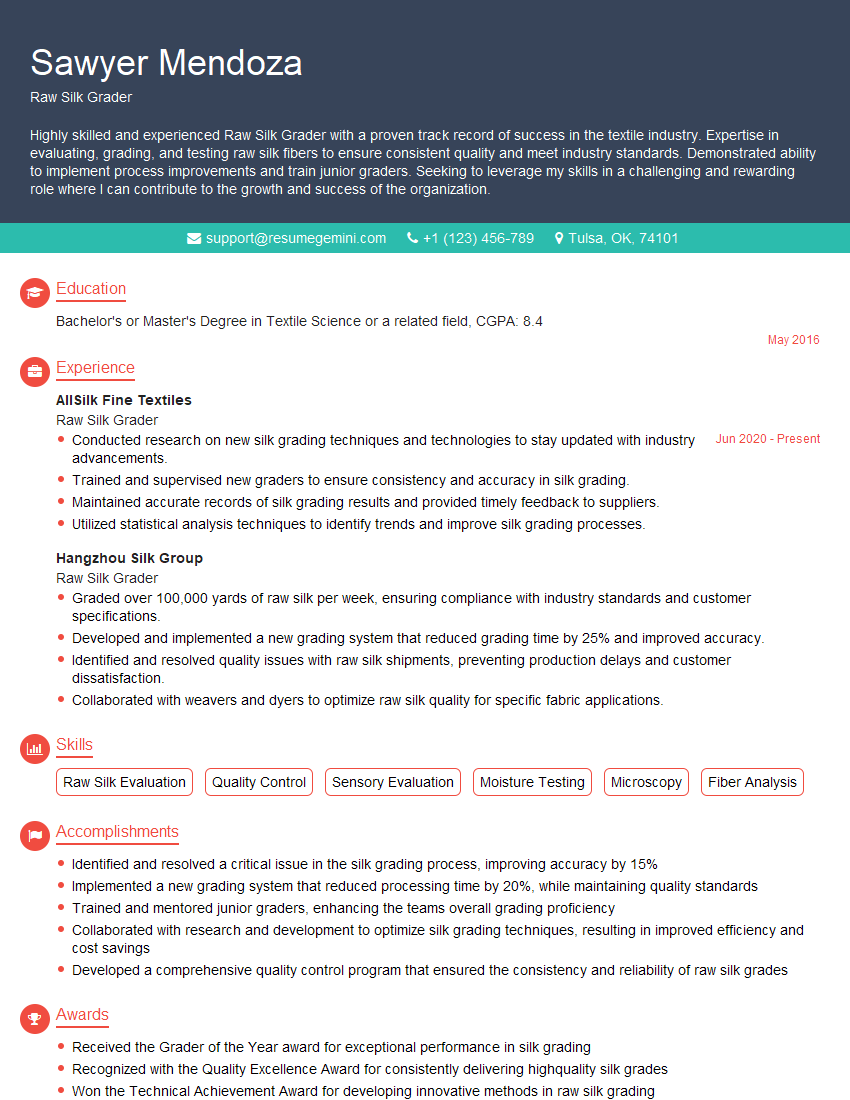

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Raw Silk Grader

1. How do you determine the quality of raw silk?

The quality of raw silk is determined based on various factors, including:

- Denier: Denier is a measure of the thickness of the silk fiber. Higher denier signifies thicker and stronger fibers.

- Filament length: The average length of raw silk fibers determines its strength and durability.

- Cleanness: The presence of impurities such as sericin and foreign materials affects the quality of raw silk.

- Color: The color of raw silk depends on the breed of silkworm and the conditions during the cocoon formation.

- Lustre: The lustre or shine of raw silk adds to its aesthetic appeal and value.

2. Describe the different stages involved in the grading of raw silk.

Initial Inspection:

- Visually examining the silk cocoons to assess their size, shape, and any visible defects.

- Separating the cocoons based on their quality and maturity.

Reeling:

- Unwinding the silk filaments from the cocoons to form continuous threads.

- Inspecting the threads for evenness, thickness, and any irregularities.

Skeining:

- Winding the reeled silk threads onto skeins of a specified size.

- Assessing the skeins for consistency and any visible flaws.

Grading:

- Using standardized criteria to assign a grade to each skein based on quality parameters such as denier, filament length, and appearance.

- Issuing a grading certificate with detailed information on the silk’s specifications.

3. What are the common defects found in raw silk and how do you identify them?

Common defects in raw silk include:

- Fibroin Break: A break in the silk fiber that results in a weak spot.

- Nepp: Small knots or entangled fibers that affect the texture and appearance of the silk.

- Boil-off Stain: Discoloration caused by improper degumming or dyeing processes.

- Double Cocoon: Two cocoons spun together, resulting in unevenness and reduced quality.

- Holes: Damage to the cocoon caused by moths or other insects.

4. Explain the importance of moisture content in raw silk and how you control it.

Moisture content plays a crucial role in the processing and storage of raw silk:

- Optimum Moisture: Raw silk with appropriate moisture content is more pliable and less likely to break during reeling and handling.

- Moisture Control: Controlling moisture levels involves using humidification or dehumidification techniques to maintain the desired moisture content.

- Packaging: Proper packaging and storage methods help maintain moisture balance and prevent damage to the silk.

5. Discuss the impact of temperature on the quality of raw silk.

Temperature has a significant impact on the quality of raw silk:

- Excessive Heat: High temperatures can damage the silk fibers, causing them to lose strength and elasticity.

- Cold Temperatures: Cold temperatures can also be detrimental, making the silk fibers brittle and prone to breakage.

- Fluctuating Temperatures: Sudden changes in temperature can cause uneven shrinkage and distortion in the silk.

- Controlled Environment: Maintaining a consistent temperature in storage and processing areas is essential to preserve the quality of raw silk.

6. Describe the testing methods used to evaluate the physical properties of raw silk.

Various testing methods are employed to assess the physical properties of raw silk, including:

- Tensile Strength Test: Measures the strength and elasticity of silk yarns under tension.

- Elongation Test: Determines the percentage of elongation that a silk yarn can withstand before breaking.

- Torsion Test: Evaluates the resistance of silk yarns to twisting.

- Compression Test: Assesses the ability of silk yarns to withstand compressive forces.

7. Explain the importance of standardization in the raw silk industry.

Standardization plays a vital role in the raw silk industry by:

- Quality Assurance: Establishing uniform grading standards ensures consistent quality and reduces variations in silk products.

- Price Stability: Standardized grading criteria facilitate fair pricing based on the quality of the raw silk.

- Global Trade: Standardized grading allows for seamless international trade, enabling buyers and sellers to communicate based on common quality parameters.

- Collaboration: Standardization fosters collaboration among stakeholders in the value chain, from producers to end-users.

- Research and Development: Standardized testing methods support research and development efforts to improve silk processing technologies.

8. Discuss the sustainability practices employed in the raw silk production process.

Sustainability practices in raw silk production include:

- Responsible Silkworm Farming: Ensuring the welfare of silkworms and maintaining biodiversity.

- Environmental Protection: Minimizing chemical usage and reducing water consumption during degumming and dyeing processes.

- Waste Management: Implementing proper disposal and recycling systems for silk waste.

- Traceability: Tracking the origin and production process of raw silk to promote transparency and accountability.

- Certifications: Obtaining certifications such as GOTS (Global Organic Textile Standard) to demonstrate sustainable practices.

9. Describe the advancements in raw silk grading technology.

Advancements in raw silk grading technology include:

- Automated Grading Systems: Utilizing sensors and computer software to analyze silk properties and assign grades.

- Non-Destructive Testing: Employing techniques like infrared spectroscopy to evaluate silk quality without damaging the fibers.

- Spectral Analysis: Analyzing the spectral properties of silk to assess its composition, color, and other characteristics.

- Machine Learning: Training algorithms to improve the accuracy and consistency of silk grading.

10. Share your experience in training and developing other silk graders.

Mentoring and Coaching:

- Providing guidance and support to junior graders, sharing knowledge and expertise.

- Monitoring their progress, providing feedback, and assisting in skill development.

Training Programs:

- Designing and delivering training modules to enhance technical skills and industry knowledge.

- Conducting mock grading sessions to provide hands-on experience.

Performance Evaluation:

- Assessing graders’ performance against established criteria.

- Providing constructive feedback and identifying areas for improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Raw Silk Grader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Raw Silk Grader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Raw Silk Graders play a crucial role in the textile industry by evaluating the quality and characteristics of raw silk fibres, which determine the final product’s value and marketability.

1. Silk Fibre Examination and Assessment

This involves using specialised equipment and techniques to examine raw silk fibres, assessing their fineness, length, strength, elasticity, colour, and lustre.

- Microscopic analysis to determine fibre diameter and length

- Tensile testing to measure fibre strength and elongation

2. Silk Lot Grading

The grader assigns grades to silk lots based on the evaluation results, such as A, B, C, or D, which indicate the quality and value of the raw material.

- Compare raw silk samples to established standards and specifications

- Determine the grade based on factors like appearance, uniformity, and absence of defects

3. Identification of Defects and Contaminants

Graders identify and document any defects in the raw silk, such as unevenness, discolouration, knots, and impurities, to ensure high-quality finished products.

- Inspect raw silk for foreign materials, such as dirt, leaves, or insects

- Identify and classify defects based on industry standards

4. Documentation and Reporting

Graders prepare detailed reports documenting the grading results, including fibre characteristics, lot grades, and defect analysis, which are crucial for quality control and traceability.

- Maintain accurate records of grading results and lot assessments

- Provide feedback to suppliers and production teams to improve raw silk quality

Interview Tips

To ace the Raw Silk Grader interview, candidates should:

1. Research the Company and Industry

Demonstrate knowledge about the specific company and the raw silk industry, including its trends, challenges, and key players.

- Visit the company’s website and social media profiles to gather information

- Read industry publications and news articles to stay updated on market dynamics

2. Highlight Relevant Skills and Experience

Emphasise your technical skills in raw silk grading, such as fibre analysis techniques, grading standards, and defect identification.

- Quantify your accomplishments and provide specific examples of your contributions to quality control

- Discuss your understanding of different types of silk and their grading systems

3. Showcase Attention to Detail and Quality

Emphasise your meticulousness, attention to detail, and commitment to delivering high-quality results.

- Describe your process for identifying and documenting raw silk defects

- Explain how you ensure the accuracy and consistency of your grading assessments

4. Prepare Industry-Specific Questions

Ask thoughtful questions that demonstrate your interest and knowledge of the industry, such as:

- What are the latest technological advancements in raw silk grading?

- How does the company ensure the traceability and sustainability of its raw silk supply chain?

Next Step:

Now that you’re armed with the knowledge of Raw Silk Grader interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Raw Silk Grader positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini