Are you gearing up for an interview for a Sample Color Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Sample Color Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

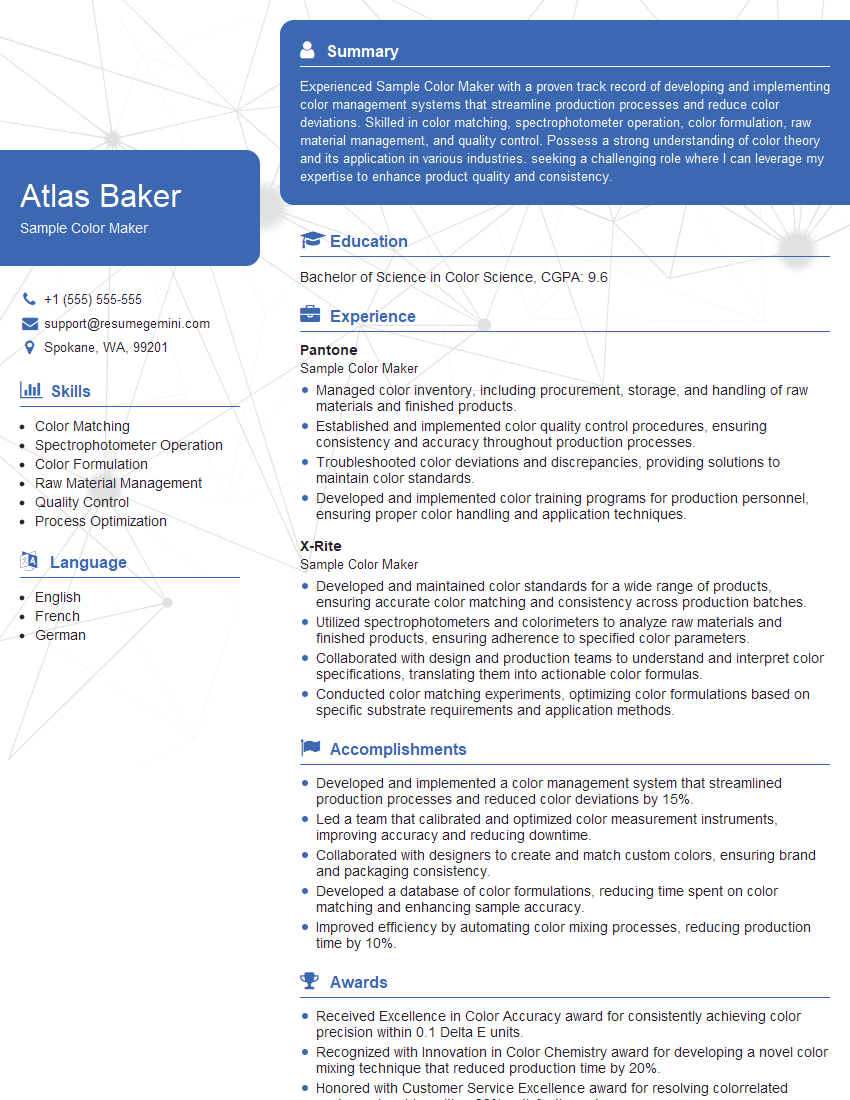

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sample Color Maker

1. What are the essential raw materials used in color making?

The essential raw materials used in color making include:

- Pigments: These are insoluble, finely divided particles that provide color to the paint.

- Binders: These are substances that hold the pigments together and form a film on the surface being painted.

- Solvents: These are liquids that dissolve the binders and allow the paint to be applied smoothly.

- Additives: These are substances that are added to the paint to improve its properties, such as its durability, gloss, and resistance to fading.

2. Explain the process of matching a sample color.

Color Matching Process

- Visually compare the sample color to a range of standard color swatches.

- Use a spectrophotometer to measure the light reflectance values of the sample color and compare them to the values of the standard colors.

- Adjust the formulation of the paint until the light reflectance values of the paint match the values of the sample color.

Factors Affecting Color Matching

- Lighting conditions

- Metamerism

- Substrate

3. Describe the different types of color measurement instruments and their applications.

The different types of color measurement instruments include:

- Spectrophotometers: These instruments measure the light reflectance values of a sample at different wavelengths. They are used for precise color matching and quality control.

- Colorimeters: These instruments measure the color of a sample by comparing it to a set of standard colors. They are less precise than spectrophotometers but are faster and easier to use.

- Densitometers: These instruments measure the opacity of a sample. They are used to control the thickness of paint films and to ensure that the paint is applied evenly.

4. What are the common defects in color matching and how can they be prevented?

Common defects in color matching include:

- Metamerism: This is a phenomenon where a color match appears to be correct under one set of lighting conditions but not under another.

- Fading: This is a gradual loss of color over time due to exposure to light, heat, or chemicals.

- Chalking: This is a condition where the paint film becomes powdery and rubs off easily.

- Blistering: This is a condition where bubbles form in the paint film.

- Cracking: This is a condition where the paint film cracks.

These defects can be prevented by using high-quality raw materials, following proper mixing and application procedures, and storing the paint in a cool, dry place.

5. What are the environmental regulations that apply to color making?

The environmental regulations that apply to color making include:

- The Clean Air Act: This act regulates the emission of air pollutants, including volatile organic compounds (VOCs) and hazardous air pollutants (HAPs).

- The Clean Water Act: This act regulates the discharge of wastewater, including wastewater from color making operations.

- The Resource Conservation and Recovery Act (RCRA): This act regulates the generation, storage, transportation, and disposal of hazardous waste.

6. What are the safety precautions that must be taken when working with color making materials?

The safety precautions that must be taken when working with color making materials include:

- Wearing appropriate personal protective equipment, such as gloves, goggles, and a respirator.

- Working in a well-ventilated area.

- Avoiding contact with skin and eyes.

- Following proper handling and storage procedures.

7. What are the emerging trends in color making?

The emerging trends in color making include:

- The use of sustainable raw materials.

- The development of new colorants.

- The use of computer-aided color matching.

- The use of nanotechnology to create new colors and effects.

8. What are the challenges facing the color making industry?

The challenges facing the color making industry include:

- The rising cost of raw materials.

- The increasing demand for sustainable products.

- The need to meet ever-changing customer demands.

- The need to comply with environmental regulations.

9. What is your favorite color and why?

My favorite color is blue. I find it to be a calming and serene color. It is also the color of the ocean and the sky, which are two of my favorite things in the world.

10. Why are you interested in working as a Sample Color Maker?

I am interested in working as a Sample Color Maker because I have a passion for color and a strong understanding of the color making process. I am also a detail-oriented and results-oriented person, which makes me well-suited for this role.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sample Color Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sample Color Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sample Color Makers are the first step in producing the colors used in paints, plastics, textiles, and other products. They play a vital role in ensuring that the colors produced are accurate and consistent with the customer’s requirements.

1. Sample Preparation

Preparing samples of colorants and dyes using a variety of techniques, such as weighing, mixing, and blending.

- Accurately measuring and weighing ingredients to create precise color formulations.

- Mixing and blending colorants and dyes to achieve the desired color and consistency.

2. Testing and Analysis

Conducting tests to determine the colorfastness, lightfastness, and other properties of colorants and dyes.

- Using spectrophotometers and other instruments to measure the color and other properties of samples.

- Evaluating the results of tests and making adjustments to color formulations as needed.

3. Data Management

Maintaining records of sample preparations, tests, and results.

- Documenting all aspects of the sample preparation and testing process.

- Storing and organizing data for future reference.

4. Research and Development

Developing new colorants and dyes, and improving existing ones.

- Researching new color trends and technologies.

- Developing and testing new color formulations.

Interview Tips

Interviewing for a Sample Color Maker position can be a daunting task, but with the right preparation, you can increase your chances of success.

1. Research the Company and Position

Take the time to learn about the company you’re applying to and the specific position you’re interested in.

- Visit the company’s website and read about their products, services, and culture.

- Review the job description carefully and identify the key skills and qualifications required.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”

- Prepare your answers to these questions in advance, and practice delivering them in a clear and concise manner.

- Use the STAR method to answer behavioral questions, which involves describing a specific situation, task, action, and result.

3. Highlight Your Skills and Experience

Make sure to highlight your skills and experience that are relevant to the position you’re applying for.

- If you have experience in sample preparation, testing, or data management, be sure to mention it.

- If you have any research or development experience, be sure to highlight that as well.

4. Ask Questions

Asking questions at the end of the interview shows that you’re interested in the position and the company.

- Prepare a few questions to ask the interviewer, such as “What are the biggest challenges facing the color industry today?” or “What are the opportunities for advancement within the company?”

- Asking thoughtful questions can help you stand out from other candidates.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sample Color Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!