Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Semiconductor Wafers Tester position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

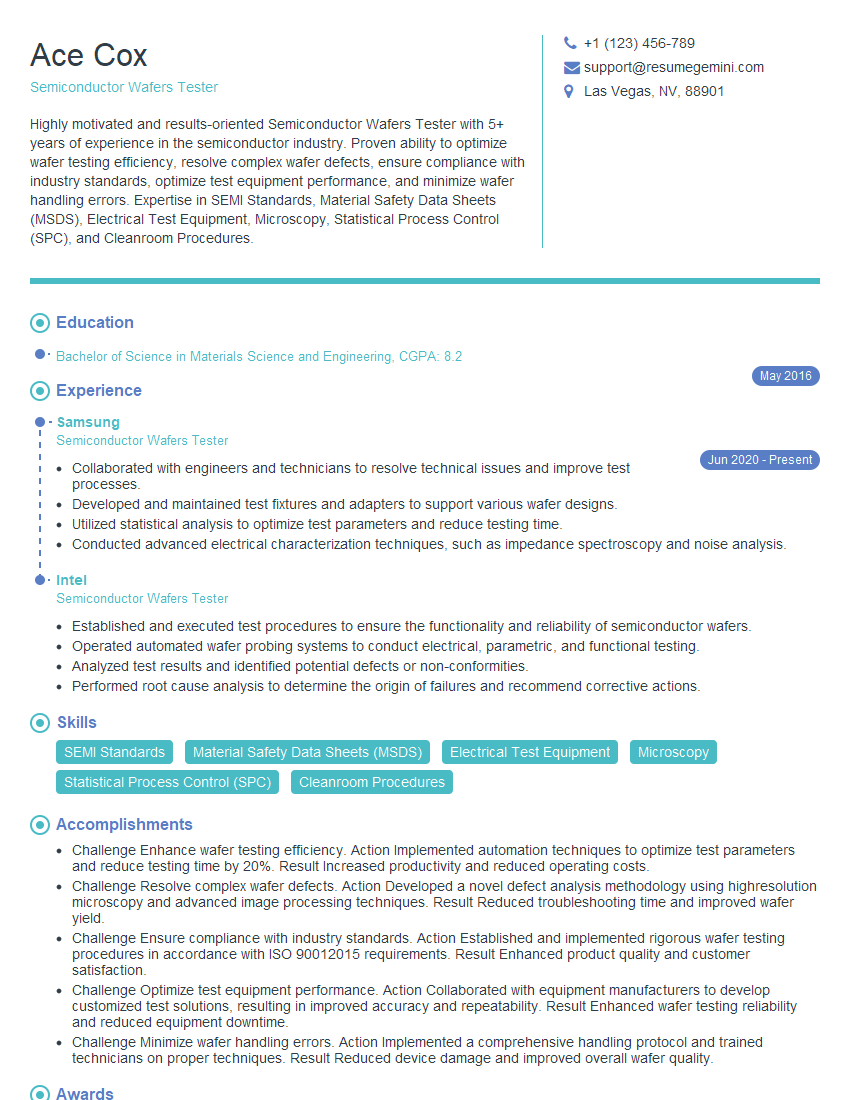

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Semiconductor Wafers Tester

1. What are the different types of semiconductor wafer tests?

There are various types of semiconductor wafer tests, including:

- Electrical test: Evaluates the electrical properties of a wafer, such as resistivity, capacitance, and leakage current.

- Physical test: Assesses the physical characteristics of a wafer, such as thickness, flatness, and surface quality.

- Chemical test: Analyzes the chemical composition of a wafer to identify impurities and defects.

- Reliability test: Determines the reliability of a wafer by subjecting it to various stress conditions, such as temperature cycling, humidity, and vibration.

2. What are the key parameters to consider when testing semiconductor wafers?

Electrical Parameters

- Resistivity

- Capacitance

- Leakage current

- Breakdown voltage

Physical Parameters

- Thickness

- Flatness

- Surface quality

- Dimensions

3. What are the different types of test equipment used for semiconductor wafer testing?

The types of test equipment used for semiconductor wafer testing include:

- Probe station: Used for electrical testing of wafers.

- Ellipsometer: Measures the thickness and refractive index of wafers.

- Scanning electron microscope (SEM): Inspects the surface and cross-section of wafers.

- X-ray diffractometer: Analyzes the crystal structure of wafers.

4. What are the challenges involved in semiconductor wafer testing?

The challenges in semiconductor wafer testing include:

- Ensuring high accuracy and repeatability of test results.

- Testing wafers with complex designs and geometries.

- Maintaining a high throughput of wafers.

- Interpreting and analyzing large amounts of test data.

5. What are the quality standards that apply to semiconductor wafer testing?

The quality standards that apply to semiconductor wafer testing include:

- ISO 9001:2015: Quality management system standard.

- IEC 60068: Environmental testing standard for electronic components.

- ASTM F42: Standard for testing the mechanical properties of semiconductor wafers.

- MIL-STD-883: Military standard for testing electronic components.

6. What is the role of automation in semiconductor wafer testing?

Automation plays a crucial role in semiconductor wafer testing by:

- Increasing the throughput of wafers.

- Improving the accuracy and repeatability of test results.

- Reducing the cost of testing.

- Providing real-time data analysis and monitoring.

7. What is the future of semiconductor wafer testing?

The future of semiconductor wafer testing involves:

- Increased use of automation and artificial intelligence (AI).

- Development of new test methods for advanced packaging technologies.

- Continued focus on improving the quality and reliability of wafers.

- Collaboration between wafer manufacturers and test equipment suppliers.

8. What are the most common defects found in semiconductor wafers?

Common defects found in semiconductor wafers include:

- Scratches and defects on the surface of the wafer.

- Impurities and contaminants in the wafer material.

- Crystal defects, such as dislocations and stacking faults.

- Electrical defects, such as shorts and opens.

9. What are the consequences of defective semiconductor wafers?

Defective semiconductor wafers can lead to:

- Reduced yield of finished devices.

- Increased costs of manufacturing.

- Lower quality of electronic products.

- Safety hazards, in some cases.

10. What are the key trends in semiconductor wafer testing?

Key trends in semiconductor wafer testing include:

- Increased use of non-destructive testing methods.

- Development of new test methods for emerging technologies, such as nanotechnology.

- Increased focus on quality and reliability.

- Collaboration between wafer manufacturers and test equipment suppliers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Semiconductor Wafers Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Semiconductor Wafers Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Semiconductor Wafers Tester holds the primary responsibility of testing and inspecting semiconductor wafers to ensure they meet specified quality standards. Their daily tasks encompass a wide range of duties, including:

1. Wafer Testing

Conducting electrical, physical, and chemical tests on semiconductor wafers using advanced testing equipment.

- Employing non-destructive testing techniques to identify defects and ensure wafer integrity.

- Interpreting test results to assess wafer performance and identify areas for improvement.

2. Data Analysis and Reporting

Analyzing test data to identify trends, patterns, and potential issues.

- Preparing detailed reports summarizing test results, defects, and recommendations.

- Communicating test findings to engineers, technicians, and management.

3. Equipment Maintenance and Calibration

Maintaining and calibrating testing equipment to ensure optimal performance.

- Conducting preventive maintenance to minimize equipment downtime and ensure accuracy.

- Performing regular calibrations to ensure equipment meets specified standards.

4. Process Improvement

Continuously evaluating testing processes to identify areas for optimization.

- Suggesting process improvements to enhance efficiency and accuracy.

- Collaborating with engineers and technicians to implement process improvements.

Interview Tips

To ace a Semiconductor Wafers Tester interview, candidates should focus on showcasing their technical skills, attention to detail, and problem-solving abilities. Here are some tips to help you prepare:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and culture. Understand the specific requirements of the Semiconductor Wafers Tester position.

- Visit the company’s website and read recent news articles to gather information.

- Review the job description carefully and note the key responsibilities and skills.

2. Practice Your Technical Skills

Refresh your knowledge of semiconductor testing techniques, equipment, and industry standards. Consider practicing on sample wafers if possible.

- Review your notes from previous courses or certifications.

- If available, practice using semiconductor testing equipment or software.

3. Highlight Your Attention to Detail

Semiconductor Wafers Testers must have an exceptional eye for detail. Prepare examples of your ability to identify and resolve discrepancies.

- Describe a situation where you identified a subtle defect on a wafer and how you resolved it.

- Explain how you use checklists or other methods to ensure accuracy in your work.

4. Demonstrate Your Problem-Solving Skills

Testers often encounter unexpected issues. Showcase your ability to analyze problems, identify root causes, and develop solutions.

- Provide an example of a time when you troubleshoot a complex testing issue and found a solution.

- Explain your approach to problem-solving and how you prioritize issues.

5. Be Prepared to Discuss Your Work Experience

Connect your skills and experiences to the specific requirements of the job. Quantify your accomplishments and provide concrete examples.

- Describe your previous roles and responsibilities in semiconductor testing.

- Share metrics or data that demonstrate your contributions to process improvement or quality.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Semiconductor Wafers Tester, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Semiconductor Wafers Tester positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.