Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Semiconductor Wafer Processing Inspector position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

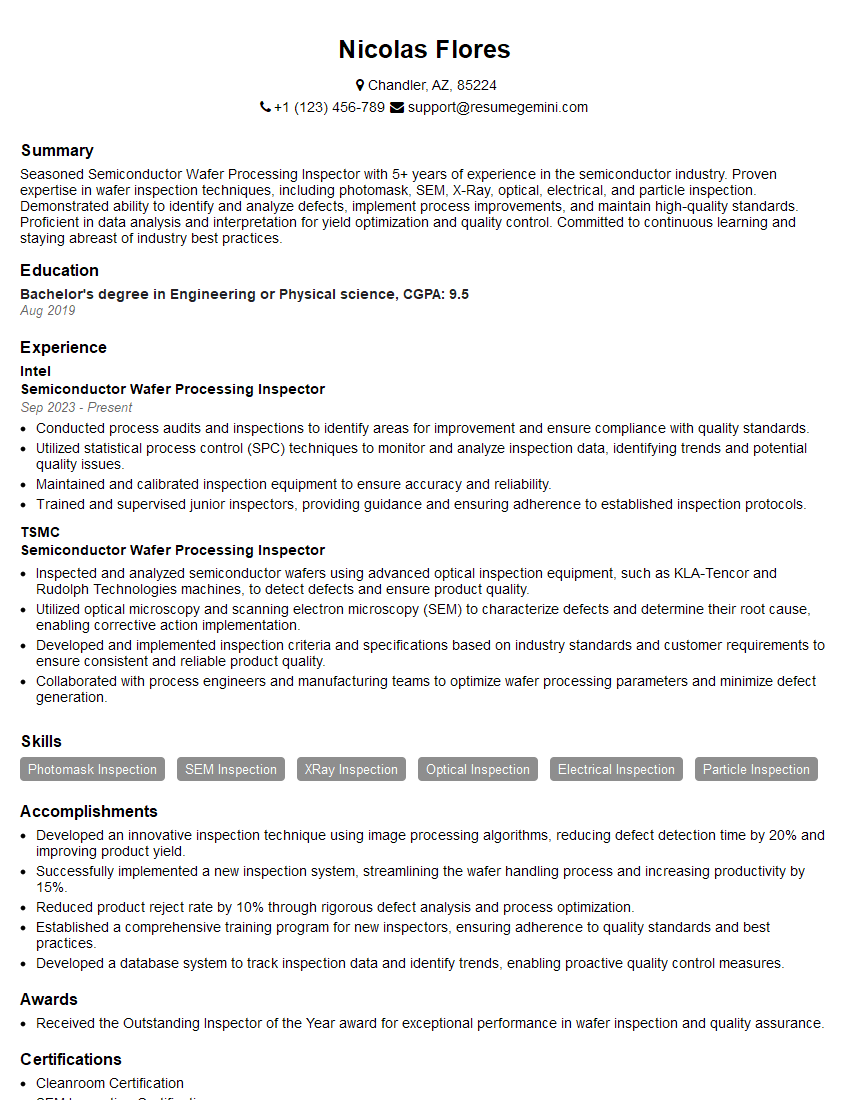

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Semiconductor Wafer Processing Inspector

1. What are the different types of defects you can inspect on a semiconductor wafer?

- Scratches: These are narrow, shallow defects that can be caused by particles or other objects that come into contact with the wafer surface.

- Pinholes: These are small, round defects that can be caused by trapped gas bubbles or other impurities.

- Cracks: These are linear defects that can be caused by mechanical stress or thermal shock.

- Voids: These are empty spaces within the wafer that can be caused by defects in the crystal structure.

- Particles: These are foreign objects that can be present on the wafer surface or in the bulk of the wafer.

2. What are the different inspection techniques used for semiconductor wafers?

Optical inspection

- Bright-field microscopy: This technique uses a microscope to examine the surface of the wafer for defects.

- Dark-field microscopy: This technique uses a microscope to examine the surface of the wafer for defects that scatter light.

Electrical inspection

- Capacitance-voltage (C-V) profiling: This technique measures the capacitance of the wafer at different voltages to determine the thickness and quality of the oxide layer.

- Current-voltage (I-V) profiling: This technique measures the current flow through the wafer at different voltages to determine the electrical properties of the wafer.

Acoustic inspection

- Ultrasonic testing: This technique uses sound waves to detect defects in the wafer.

- Laser scanning acoustic microscopy (LSAM): This technique uses a laser to generate sound waves that can be used to detect defects in the wafer.

3. What are the key factors that affect the accuracy of wafer inspection?

- The type of inspection technique used

- The quality of the inspection equipment

- The experience of the inspector

- The environment in which the inspection is conducted

- The presence of defects on the wafer

4. What are the different types of reports that a wafer inspection can generate?

- Defect maps: These maps show the location and size of defects on the wafer.

- Yield reports: These reports show the number of defects per wafer and the percentage of wafers that are free of defects.

- Trend reports: These reports show the number of defects over time and can be used to identify trends in the manufacturing process.

5. What are the most common challenges faced by wafer inspectors?

- The increasing complexity of semiconductor devices: As semiconductor devices become more complex, the number of potential defects increases.

- The need for higher yields: As the demand for semiconductor devices increases, the need for higher yields increases.

- The need for faster turnaround times: As the semiconductor industry becomes more competitive, the need for faster turnaround times increases.

6. What are the best practices for wafer inspection?

- Use the correct inspection technique for the type of defect you are looking for.

- Use high-quality inspection equipment that is properly calibrated.

- Train inspectors to a high standard.

- Inspect wafers in a clean environment.

- Document your inspection results in a clear and concise manner.

7. What are the future trends in wafer inspection?

- The use of artificial intelligence (AI): AI can be used to automate the inspection process and to identify defects that are difficult to detect with traditional methods.

- The development of new inspection techniques: New inspection techniques are being developed to meet the challenges of inspecting complex semiconductor devices.

- The use of inline inspection: Inline inspection can be used to inspect wafers during the manufacturing process.

8. How do you stay up-to-date on the latest wafer inspection technologies?

- Attend industry conferences and workshops.

- Read trade publications and journals.

- Network with other wafer inspectors.

- Get involved in professional organizations.

- Take online courses or training programs.

9. What are your strengths as a wafer inspection technician?

- I have a strong understanding of the different types of defects that can occur on semiconductor wafers.

- I am proficient in a variety of wafer inspection techniques.

- I am able to identify defects quickly and accurately.

- I am able to work independently and as part of a team.

- I am committed to quality and accuracy.

10. What are your career goals?

- I want to continue to develop my skills and knowledge in the field of wafer inspection.

- I want to become a leader in the field of wafer inspection.

- I want to make a significant contribution to the semiconductor industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Semiconductor Wafer Processing Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Semiconductor Wafer Processing Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Semiconductor Wafer Processing Inspector plays a pivotal role in maintaining the quality and accuracy of semiconductor wafer fabrication. Their responsibilities encompass:

1. Wafer Inspection and Analysis

Conducting meticulous visual inspections of wafers to detect defects, anomalies, and contamination using optical microscopes, scanning electron microscopes (SEMs), and automated inspection systems

- Identifying and categorizing defects based on size, shape, and location

- Documenting findings and providing detailed reports on defect analysis

2. Process Monitoring and Control

Monitoring and evaluating semiconductor manufacturing processes to ensure compliance with established specifications and standards

- Inspecting raw materials and equipment to verify adherence to process parameters

- Identifying potential process deviations and implementing corrective actions to prevent defects

3. Data Analysis and Reporting

Analyzing inspection data to identify trends, patterns, and potential areas for improvement

- Preparing statistical reports and presenting findings to management and engineering teams

- Contributing to continuous process improvement efforts

4. Equipment Maintenance and Calibration

Performing regular maintenance and calibration of inspection equipment to ensure accuracy and reliability

- Replacing consumables, aligning systems, and troubleshooting operational issues

- Maintaining equipment records and adhering to calibration schedules

Interview Tips

To excel in an interview for a Semiconductor Wafer Processing Inspector position, it is crucial to demonstrate your technical expertise, attention to detail, and problem-solving abilities. Here are some tips to help you prepare:

1. Research the Company and Role

Thoroughly research the company’s semiconductor manufacturing processes and the specific role you are applying for. This will give you a deeper understanding of the company’s products, technologies, and expectations for this position.

- Visit the company’s website and review their latest news and developments

- Read industry publications and articles to familiarize yourself with current industry trends and best practices

2. Highlight Your Technical Skills

Emphasize your proficiency in semiconductor wafer inspection techniques, including optical microscopy, SEM analysis, and automated inspection systems.

- Provide specific examples of your experience in identifying and categorizing defects

- Discuss your knowledge of different defect types and their potential impact on semiconductor performance

3. Demonstrate Your Problem-Solving Abilities

Interviewers will be interested in your ability to identify and resolve process issues. Share examples of how you have identified process deviations, analyzed data, and implemented corrective actions to improve wafer quality.

- Describe a situation where you identified a recurring defect and developed a solution to eliminate it

- Explain how you used statistical analysis to determine the root cause of a process problem

4. Be Prepared to Discuss Your Quality Assurance Experience

Semiconductor wafer processing requires strict adherence to quality standards. Highlight your experience in quality assurance procedures, including documentation, reporting, and continuous improvement.

- Discuss your role in maintaining inspection records and ensuring compliance with quality standards

- Explain how you have contributed to process improvement initiatives and reduced defect rates

Next Step:

Now that you’re armed with the knowledge of Semiconductor Wafer Processing Inspector interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Semiconductor Wafer Processing Inspector positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini