Feeling lost in a sea of interview questions? Landed that dream interview for Set-Up and Lay-Out Inspector but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Set-Up and Lay-Out Inspector interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

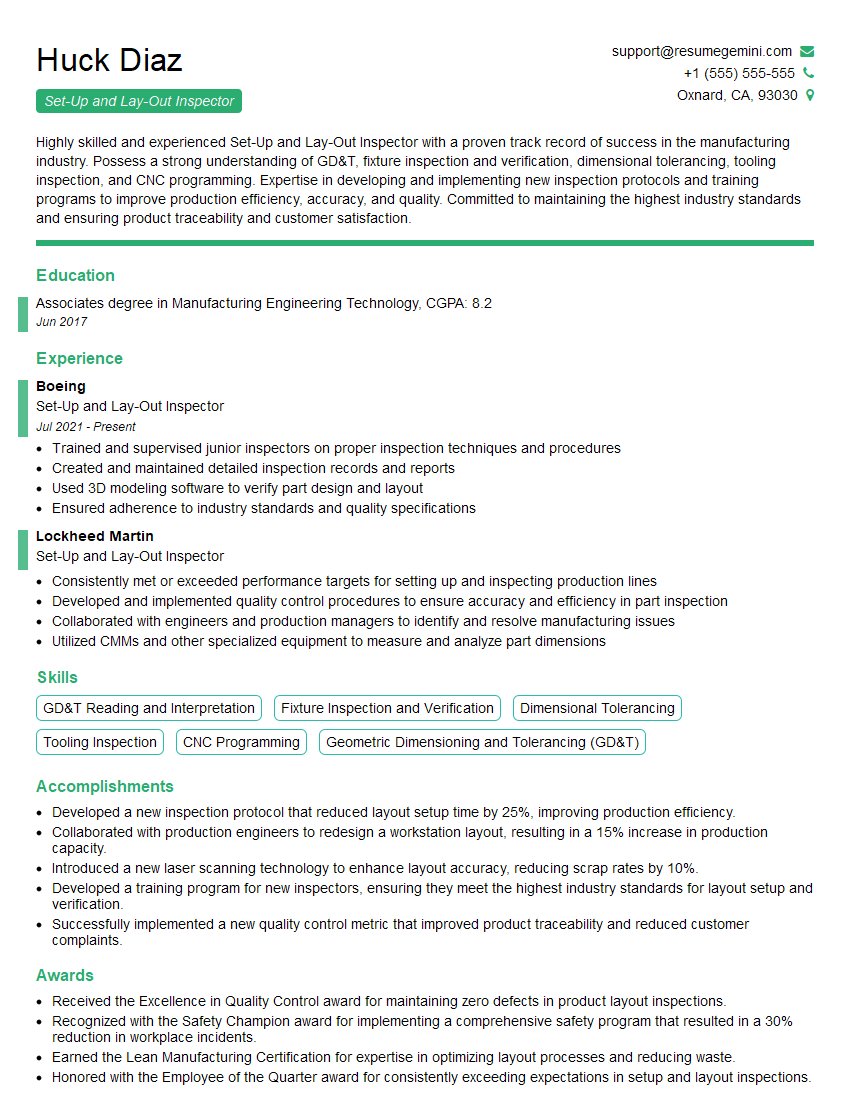

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Set-Up and Lay-Out Inspector

1. What are the key responsibilities of a Set-Up and Lay-Out Inspector?

- Inspecting and verifying the accuracy of equipment setup and layout on the production floor.

- Ensuring that all equipment is operating within specified tolerances and safety standards.

- Documenting findings and reporting any deviations or issues to management.

- Providing guidance and support to production staff on proper equipment setup and layout techniques.

- Maintaining a clean and organized work environment.

2. What are the essential skills and qualifications required for a Set-Up and Lay-Out Inspector?

- In-depth knowledge of manufacturing processes and equipment.

- Strong understanding of quality control principles and practices.

- Excellent attention to detail and problem-solving abilities.

- Proficient in using inspection tools and techniques.

- Ability to work independently and as part of a team.

3. Can you walk me through the steps involved in conducting an equipment layout inspection?

- Gather necessary documentation, including equipment specifications, drawings, and work instructions.

- Visually inspect the equipment setup and layout against the specified requirements.

- Check for proper alignment, clearances, and safety features.

- Test the equipment to ensure it is functioning correctly.

- Document findings and report any deviations or issues.

4. How do you handle situations when you identify deviations or issues during an inspection?

- Immediately report the findings to management and relevant stakeholders.

- Communicate clearly the nature of the issue and its potential impact.

- Work with teams to determine the root cause and develop corrective actions.

- Monitor progress and ensure that corrective actions are implemented effectively.

5. How do you stay updated on industry best practices and advancements in equipment setup and layout?

- Attend industry conferences and webinars.

- Read technical publications and journals.

- Network with other professionals in the field.

- Participate in training and development programs.

6. What are some common challenges faced by Set-Up and Lay-Out Inspectors?

- Managing the workload and prioritizing tasks effectively.

- Communicating findings and recommendations to non-technical stakeholders.

- Staying up-to-date with rapidly changing manufacturing technologies.

- Handling production downtime due to equipment issues.

7. How do you ensure that your inspections are thorough and accurate?

- Following a structured inspection checklist.

- Paying attention to even the smallest details.

- Using calibrated inspection tools and equipment.

- Verifying findings through multiple inspections.

8. Can you explain the importance of proper equipment setup and layout in the manufacturing process?

- Optimizing productivity and efficiency.

- Reducing production costs.

- Ensuring product quality and consistency.

- Improving workplace safety.

9. How do you prioritize tasks when multiple issues or deviations are identified during an inspection?

- Assessing the severity and potential impact of each issue.

- Considering the dependencies between different issues.

- Consulting with management and relevant stakeholders.

- Focusing on addressing the most critical issues first.

10. Can you describe a time when you faced a particularly challenging situation as a Set-Up and Lay-Out Inspector? How did you overcome it?

Provide a specific example of a situation where you demonstrated your problem-solving skills, technical knowledge, and ability to handle complex challenges.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Set-Up and Lay-Out Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Set-Up and Lay-Out Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Set-Up and Lay-Out Inspectors are responsible for ensuring that the equipment on a production line is set up and laid out correctly, and that products are produced according to specifications. Their key responsibilities include:

1. Set-up and Adjust Equipment

Set up and adjust equipment according to specifications, using precision measuring tools and equipment.

- Inspect equipment for damage or wear.

- Install and adjust tooling, fixtures, and other equipment.

2. Verify Equipment Set-ups

Verify equipment set-ups using measuring tools and gauges.

- Check dimensions, tolerances, and other specifications.

- Ensure that equipment is operating properly.

3. Inspect Production Runs

Inspect production runs to ensure that products are produced according to specifications.

- Check dimensions, tolerances, and other specifications.

- Identify and correct any defects or non-conformities.

4. Document Inspections and Findings

Document inspections and findings, and report any non-conformities to the appropriate personnel.

- Maintain records of inspections and corrective actions.

- Communicate inspection results to production personnel.

Interview Tips

To ace an interview for a Set-Up and Lay-Out Inspector position, it is important to highlight your skills and experience in the following areas:

1. Set-up and Adjustment of Equipment

Be prepared to discuss your experience in setting up and adjusting equipment, using precision measuring tools and equipment.

- Provide examples of specific equipment you have set up and adjusted.

- Explain how you verified the accuracy of your set-ups.

2. Inspection of Equipment and Production Runs

Be prepared to discuss your experience in inspecting equipment and production runs, and identifying and correcting any defects or non-conformities.

- Provide examples of specific defects or non-conformities you have identified and corrected.

- Explain how you documented your inspections and findings.

3. Communication and Interpersonal Skills

Be prepared to discuss your communication and interpersonal skills, as you will need to be able to interact with production personnel, supervisors, and other stakeholders.

- Provide examples of how you have communicated inspection results and corrective actions to production personnel.

- Explain how you have worked with others to resolve issues and improve production processes.

4. Attention to Detail

Be prepared to demonstrate your attention to detail, as this is essential for this role.

- Provide examples of how you have ensured that equipment was set up and adjusted to precise specifications.

- Explain how you have inspected products to ensure that they met all quality standards.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Set-Up and Lay-Out Inspector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!