Feeling lost in a sea of interview questions? Landed that dream interview for Silk Screen Printing Racker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Silk Screen Printing Racker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

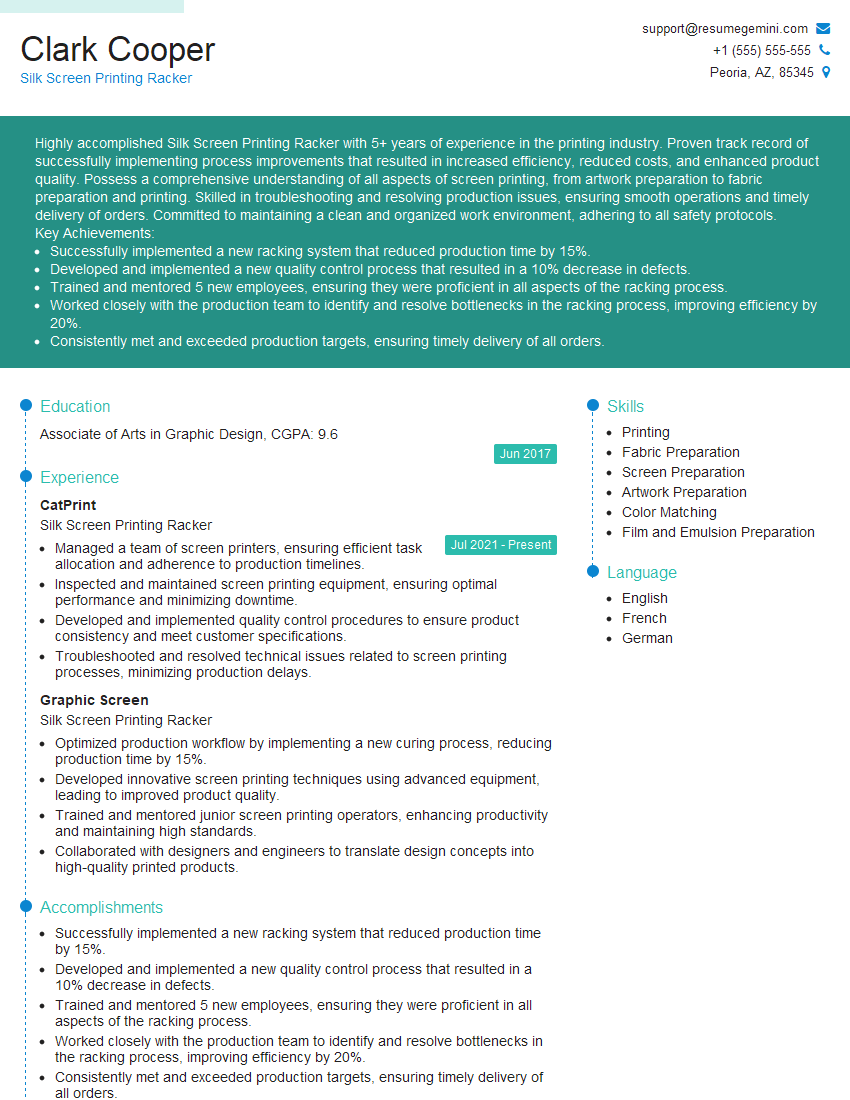

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Silk Screen Printing Racker

1. What are the different types of silk screen printing frames?

- Wood frames: Wood frames are the most common type of silk screen printing frame. They are lightweight and inexpensive, and they can be easily assembled and disassembled.

- Metal frames: Metal frames are more durable than wood frames, and they can withstand higher printing pressures. They are also more expensive than wood frames.

- Plastic frames: Plastic frames are lightweight and durable, and they are resistant to chemicals. They are also more expensive than wood frames.

2. What is the difference between a single-color and a multi-color silkscreen printing press?

subheading of the answer

- Single-color silkscreen printing presses can only print one color at a time. They are typically used for small-scale printing jobs.

- Multi-color silkscreen printing presses can print multiple colors at a time. They are typically used for large-scale printing jobs.

subheading of the answer

- Multi-color silkscreen printing presses are more expensive than single-color silkscreen printing presses.

- Multi-color silkscreen printing presses require more setup time than single-color silkscreen printing presses.

3. What are the different types of silk screen printing inks?

- Water-based inks: Water-based inks are made from water and pigments. They are easy to clean up and they are non-toxic.

- Solvent-based inks: Solvent-based inks are made from solvents and pigments. They are more durable than water-based inks, but they are also more toxic.

- UV-curable inks: UV-curable inks are made from monomers and oligomers that are cured by ultraviolet light. They are very durable and they are resistant to chemicals.

4. What is the difference between a squeegee and a flood bar?

- Squeegees are used to push the ink through the screen onto the substrate.

- Flood bars are used to evenly distribute the ink across the screen.

5. What are the different types of silk screen printing substrates?

- Paper: Paper is the most common substrate for silk screen printing. It is inexpensive and easy to print on.

- Fabric: Fabric is another popular substrate for silk screen printing. It can be used to create clothing, home décor, and other products.

- Plastic: Plastic is a durable substrate that can be used to create a variety of products, such as signs, toys, and packaging.

6. What are the different types of silk screen printing machines?

- Manual silk screen printing machines: Manual silk screen printing machines are operated by hand. They are typically used for small-scale printing jobs.

- Automatic silk screen printing machines: Automatic silk screen printing machines are operated by a computer. They are typically used for large-scale printing jobs.

7. What are the different types of silk screen printing screens?

- Mesh screens: Mesh screens are made from a fine mesh fabric. They are used to print detailed images.

- Stencil screens: Stencil screens are made from a solid material, such as Mylar or acetate. They are used to print simple images.

8. What are the different types of silk screen printing emulsions?

- Diazo emulsions: Diazo emulsions are the most common type of silk screen printing emulsion. They are easy to use and they produce high-quality prints.

- Photopolymer emulsions: Photopolymer emulsions are more durable than diazo emulsions. They are also more expensive and they require more time to expose.

9. What are the different types of silk screen printing curing methods?

- Air drying: Air drying is the most common curing method for silk screen printing. It is inexpensive and easy to do.

- Heat curing: Heat curing is a more durable curing method than air drying. It requires a heat press or a conveyor dryer.

- UV curing: UV curing is a very durable curing method that uses ultraviolet light to cure the ink.

10. What are the different types of silk screen printing finishing methods?

- Coating: Coating can be used to protect the print from scratches and fading.

- Lamination: Lamination can be used to give the print a glossy or matte finish.

- Foiling: Foiling can be used to add a metallic finish to the print.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Silk Screen Printing Racker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Silk Screen Printing Racker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Silk Screen Printing Racker is accountable for transporting and loading material to and from active print stations. Key responsibilities include transporting screens and materials, ensuring quality, and maintaining a clean and safe work environment.

1. Materials Handling and Transportation

The racker is responsible for the movement of materials within the print shop, including:

- Transporting screens and frames to and from print stations

- Loading and unloading materials from racks and carts

- Operating forklifts or other equipment to move heavy items

2. Quality Assurance

The racker is responsible for ensuring the quality of the printed materials, including:

- Inspecting screens for defects

- Checking the quality of printed materials

- Reporting any defects or problems to the supervisor

3. Workplace Maintenance

The racker is responsible for maintaining a clean and safe work environment, including:

- Cleaning and maintaining equipment

- Sweeping and mopping floors

- Removing trash and debris

4. Customer Service

The racker may also be responsible for providing customer service, including:

- Answering questions from customers

- Providing information about products and services

- Resolving customer complaints

Interview Tips

To ace the interview for a Silk Screen Printing Racker position, candidates should prepare by researching the company, practicing their answers to common interview questions, and dressing professionally. Here are some specific tips to help candidates prepare:

1. Research the Company

Before the interview, candidates should take some time to research the company, including its history, products or services, and culture. This will help candidates to understand the company’s needs and to tailor their answers to the specific position. Candidates can find information about the company on their website, in news articles, and on social media.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that candidates should be prepared to answer, such as:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with silk screen printing?

- How do you handle working in a fast-paced environment?

Candidates should practice answering these questions in a clear and concise manner, and they should be able to provide specific examples to support their answers.

3. Dress Professionally

First impressions matter, so candidates should dress professionally for the interview. This means wearing clean, pressed clothes that are appropriate for a business setting. Candidates should also avoid wearing excessive jewelry or makeup.

4. Be Enthusiastic and Positive

Candidates should be enthusiastic and positive during the interview. They should demonstrate their interest in the position and the company, and they should be able to articulate why they are the best candidate for the job. Candidates should also be prepared to ask questions about the position and the company, which shows that they are engaged and interested.

5. Follow Up

After the interview, candidates should follow up with the interviewer to thank them for their time and to reiterate their interest in the position. Candidates can also use this opportunity to ask any additional questions that they may have.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Silk Screen Printing Racker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Silk Screen Printing Racker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.