Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Stave Grader position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

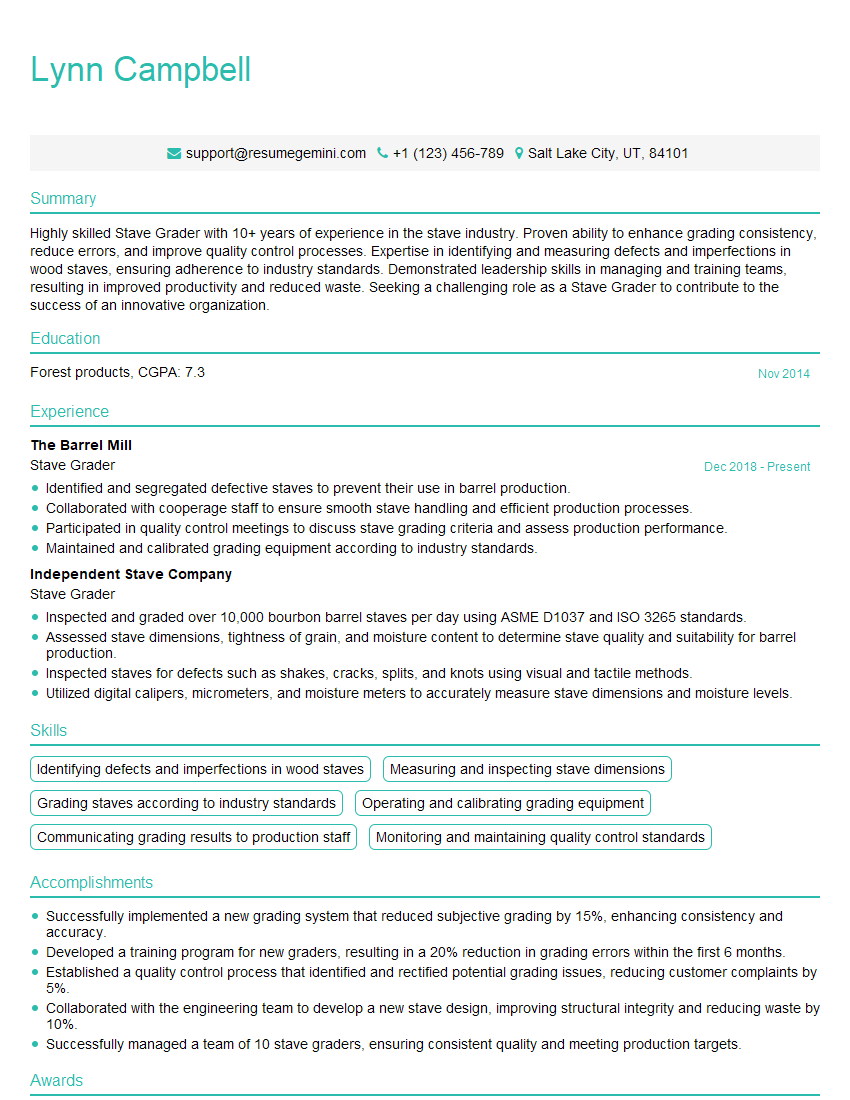

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stave Grader

1.Describe the grading system used to evaluate staves for quality?

- The grading system for staves is based on a combination of factors, including:

- Size and shape

- Knots and other defects

- Grain pattern and density

- Moisture content

- The grading system is used to determine the suitability of staves for use in barrels and other applications.

2.Explain the process of kiln drying staves?

Purpose of Kiln Drying

- Reduces the moisture content of staves to prevent decay and mold growth.

- Enhances the stability and strength of the staves.

Process Steps

- Staves are placed in a kiln, which is a controlled environment with specific temperature and humidity levels.

- Warm air is circulated through the kiln to remove moisture from the staves.

- The temperature and humidity levels are gradually adjusted to ensure even drying throughout the staves.

3.What are the common defects found in staves and how do you identify them?

- Knots: Knots are caused by branches growing within the tree and are visible as dark, oval-shaped areas on the stave.

- Splits: Splits are cracks in the stave that can occur during drying or handling.

- Shake: Shake is a separation of the wood fibers along the grain that can weaken the stave.

- Checking: Checking is a network of small cracks that occur on the surface of the stave due to drying.

- Warp: Warp is a bending or twisting of the stave that can occur during drying or storage.

- These defects can be identified by visually inspecting the staves and by tapping them with a hammer to listen for any hollow sounds.

4.How do you determine the moisture content of a stave?

- There are several methods for determining the moisture content of a stave:

- Oven drying: This method involves drying a sample of the stave in an oven at a specific temperature and then weighing the sample before and after drying to calculate the moisture loss.

- Moisture meter: A moisture meter is a non-destructive device that measures the electrical resistance of the stave to estimate the moisture content.

- Equilibrium moisture content: This method involves placing the stave in a controlled environment with a specific temperature and humidity and then measuring the moisture content of the stave once it has reached equilibrium with the environment.

5.What are the key characteristics of a high-quality stave?

- Grain pattern: High-quality staves have a straight grain pattern with minimal knots and defects.

- Density: High-quality staves are dense and have a tight grain structure.

- Moisture content: The moisture content of high-quality staves is carefully controlled to prevent decay and mold growth.

- Size and shape: High-quality staves are cut to precise dimensions and have a consistent shape.

- Appearance: High-quality staves are free from any visible defects or blemishes.

6.How do you sort and grade staves for different applications?

- Staves are sorted and graded based on their quality and intended application.

- High-quality staves with minimal defects are used for premium applications, such as barrels for aging wine and spirits.

- Staves with minor defects may be used for less demanding applications, such as barrels for storing industrial liquids.

- Staves that do not meet the minimum quality standards are typically discarded.

7.What are the safety precautions that need to be taken when handling and storing staves?

- Wear appropriate safety gear, such as gloves, safety glasses, and a hard hat.

- Use proper lifting techniques when handling staves to avoid injury.

- Store staves in a dry, well-ventilated area to prevent decay and mold growth.

- Regularly inspect staves for any damage or defects.

- Dispose of damaged or defective staves properly.

8.What are the environmental regulations that apply to the stave industry?

- Stave mills must comply with regulations regarding the sustainable harvesting of timber.

- Stave drying operations must meet air quality standards to minimize emissions.

- Waste from stave mills must be disposed of in an environmentally responsible manner.

- Stave mills must have a plan in place for preventing and responding to spills and other environmental incidents.

9.What are the latest trends and innovations in the stave industry?

- Stave mills are investing in new technologies to improve the efficiency and sustainability of stave production.

- There is a growing demand for staves made from alternative materials, such as recycled plastic and bamboo.

- Stave mills are exploring new finishing techniques to enhance the appearance and durability of staves.

10.What are the challenges facing the stave industry in the future?

- The stave industry faces challenges related to the availability of high-quality timber.

- Stave mills must adapt to changing environmental regulations.

- The stave industry must compete with other industries for resources, such as labor and energy.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stave Grader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stave Grader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Stave Graders play a crucial role in the lumber industry by inspecting and grading wooden barrels, also known as staves. Their key responsibilities include:

1. Inspecting and Grading Staves

Stave Graders thoroughly examine the staves to assess their quality and determine their grade. They look for defects, knots, cracks, splits, and other imperfections using specialized tools and equipment.

- Identify and categorize defects or imperfections based on established grading standards

- Measure and evaluate the dimensions of staves to ensure they meet specifications

2. Determining Grade and Value

Based on their inspection, Graders assign a grade to each stave, which indicates its quality and value. The grade is typically based on a combination of factors, including the number and severity of defects, the moisture content, and the grain pattern.

- Assign specific grades to staves, such as Prime, Select, or Standard, according to established grading rules

- Determine the market value of staves based on their grade and other factors

3. Ensuring Compliance with Standards

Stave Graders ensure that the staves meet the required quality standards and specifications. They adhere to industry standards and regulations, as well as customer requirements.

- Inspect staves to ensure they meet specified dimensions, tolerances, and quality criteria

- Maintain records and documentation related to the grading process and quality control

4. Maintaining Equipment and Tools

Graders are responsible for maintaining their equipment and tools to ensure accuracy and efficiency. They regularly calibrate and adjust their tools and equipment to ensure reliable measurements and grading.

- Calibrate and maintain grading equipment, such as moisture meters and grading sticks

- Keep tools and equipment clean and in good working condition

Interview Tips

To ace an interview for a Stave Grader position, it’s essential to prepare thoroughly and highlight your relevant skills and experience. Here are some tips for interview preparation:

1. Research the Company and the Role

Research the company you’re applying to and the specific role of a Stave Grader. This will help you understand the company’s culture, industry, and the requirements of the position.

- Visit the company’s website to learn about their products, services, and values.

- Read industry publications and articles to stay up-to-date on the latest trends and best practices.

2. Highlight Your Experience and Skills

In your resume and during the interview, emphasize your relevant experience and skills for the role. Quantify your accomplishments whenever possible using numbers and specific examples.

- Showcase your knowledge of lumber grading standards and the ability to identify defects.

- Highlight your experience in using grading equipment and tools.

3. Practice Answering Common Interview Questions

Prepare for common interview questions by practicing your answers and rehearsing your delivery. This will boost your confidence and help you articulate your abilities effectively.

- Prepare for questions related to your grading experience, such as “Describe your process for grading staves.”

- Practice answering questions about your knowledge of lumber industry regulations and standards.

4. Be Enthusiastic and Ask Questions

During the interview, demonstrate your enthusiasm for the role and the company. Ask thoughtful questions to show your interest and engagement in the position.

- Inquire about the company’s quality control procedures and the role of the Stave Grader in the process.

- Ask about opportunities for professional development and career growth within the organization.

5. Follow Up After the Interview

After the interview, send a thank-you note to the interviewer. Reiterate your interest in the position and highlight any specific aspects of the conversation that you found particularly engaging.

- Express your appreciation for the interviewer’s time and provide your contact information.

- Restate your key qualifications and how they align with the company’s needs.

Next Step:

Now that you’re armed with the knowledge of Stave Grader interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Stave Grader positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini