Feeling lost in a sea of interview questions? Landed that dream interview for Stencil Inspector but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Stencil Inspector interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

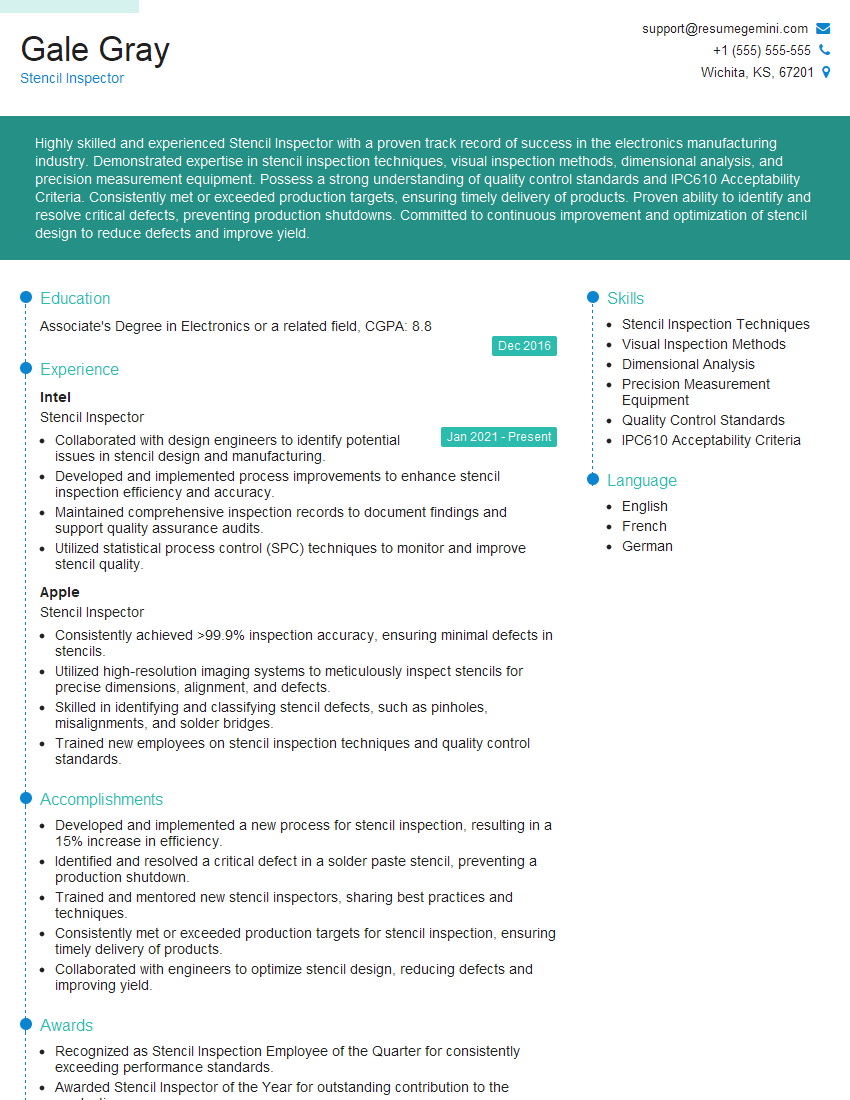

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stencil Inspector

1. How would you inspect a stencil for defects?

To inspect a stencil for defects, you would need the following equipment:

- A magnifying glass or microscope

- A light source

- A set of tweezers

Once you have gathered your equipment, you can begin the inspection process:

- Start by examining the stencil under magnification.

- Look for any breaks, tears, or other damage to the stencil.

- Check the alignment of the stencil to the substrate.

- Inspect the solder paste deposit for any irregularities.

If you find any defects, you will need to repair or replace the stencil before using it to print solder paste.

2. What are the different types of stencil defects?

Types of Stencil Defects

- Bridging

- Solder Balling

- Tombstoning

- Head in Pillow

- Solder Skip

Causes of Stencil Defects

- Incorrect stencil design

- Improper stencil manufacturing

- Misalignment of the stencil to the substrate

- Incorrect solder paste application

- Reflow oven problems

3. What are the causes of stencil defects?

The causes of stencil defects can be varied, but some of the most common include:

- Incorrect stencil design

- Improper stencil manufacturing

- Misalignment of the stencil to the substrate

- Incorrect solder paste application

- Reflow oven problems

4. How can you prevent stencil defects?

There are a number of things you can do to prevent stencil defects, including:

- Using a high-quality stencil

- Properly aligning the stencil to the substrate

- Using the correct amount of solder paste

- Reflowing the solder paste at the correct temperature

5. What are the different types of stencil materials?

The different types of stencil materials include:

- Metal

- Plastic

- Ceramic

- Kapton

each has its own advantages and disadvantages:

- Metal stencils are very durable and can be used for a long time.

- Plastic stencils are less durable than metal stencils, but they are also less expensive.

- Ceramic stencils are very durable and can be used for a long time, but they are also more expensive than metal stencils.

- Kapton stencils are very flexible and can be used for a variety of applications, but they are also less durable than metal, plastic, or ceramic stencils.

6. What is the difference between a laser cut stencil and a chemical etched stencil?

Laser cut stencils are created using a laser to cut the stencil out of a sheet of metal or plastic.

Chemical etched stencils are created using a chemical process to etch the stencil out of a sheet of metal.

Laser cut stencils are generally more precise than chemical etched stencils, but they can also be more expensive.

Chemical etched stencils are generally less expensive than laser cut stencils, but they can also be less precise.

7. What are the different types of stencil apertures?

The different types of stencil apertures include:

- Round

- Square

- Rectangular

- Oval

- Triangular

The type of stencil aperture that you use will depend on the application.

8. What is the purpose of a solder mask?

A solder mask is a protective layer that is applied to a printed circuit board (PCB) to prevent solder from bridging between adjacent conductors.

Solder mask is typically made of a polymer material, such as epoxy or acrylic.

Solder mask is applied to the PCB after the solder paste has been printed and reflowed.

9. What are the different types of solder masks?

The different types of solder masks include:

- Liquid solder mask

- Film solder mask

- Dry film solder mask

The type of solder mask that you use will depend on the application.

10. What is the difference between a stencil and a solder mask?

A stencil is a metal or plastic sheet that is used to print solder paste onto a PCB.

A solder mask is a protective layer that is applied to a PCB to prevent solder from bridging between adjacent conductors.

Stencils are typically used in the assembly of PCBs, while solder masks are applied after the PCBs have been assembled.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stencil Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stencil Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Stencil Inspector plays a crucial role in ensuring the quality and accuracy of stencils used in the manufacturing process. Their responsibilities involve:

1. Inspecting Stencils for Flaws

Inspecting stencils thoroughly to identify any defects, such as breaks, cracks, or misalignments, that could compromise the quality of the printed products.

- Utilizing specialized tools and equipment to conduct meticulous examinations.

- Documenting and reporting any detected flaws for further investigation and corrective action.

2. Verifying Design Specifications

Comparing stencils to design specifications to ensure they meet the required dimensions, tolerances, and other technical requirements.

- Measuring and analyzing stencils using precision instruments to ensure accuracy.

- Collaborating with engineers and designers to resolve any discrepancies or deviations from specifications.

3. Maintaining Stencil Inventory

Maintaining an organized and up-to-date inventory of stencils, including tracking their usage, storage conditions, and inspection records.

- Implementing inventory management systems to monitor the availability and allocation of stencils.

- Coordinating with production teams to ensure timely delivery and efficient utilization of stencils.

4. Troubleshooting and Reporting Issues

Identifying and troubleshooting any issues related to stencil performance or quality, and reporting them to the appropriate personnel.

- Analyzing production data to identify trends and potential problems.

- Providing technical insights and recommendations for corrective actions to improve stencil performance.

Interview Tips

To ace the interview for a Stencil Inspector position, candidates should consider the following tips:

1. Research the Industry and Company

Familiarize yourself with the stencil manufacturing industry, its processes, and the specific company you are interviewing with. This demonstrates your interest and shows that you have taken the time to learn about their operations.

- Visit the company’s website and social media pages to gather information.

- Read industry publications and articles to stay up-to-date on trends and best practices.

2. Highlight Your Technical Skills

Emphasize your proficiency in using precision instruments, such as microscopes, calipers, and measuring tools. Describe your experience in inspecting and verifying the quality of stencils.

- Provide specific examples of projects or tasks where you demonstrated your technical abilities.

- Be prepared to discuss your understanding of stencil design specifications and tolerances.

3. Showcase Your Problem-Solving Abilities

Highlight your ability to identify and troubleshoot problems related to stencil performance. Share examples of how you analyzed data, identified root causes, and implemented solutions.

- Emphasize your analytical thinking skills and attention to detail.

- Explain how you have collaborated with other team members to resolve complex issues.

4. Be Enthusiastic and Professional

Convey your enthusiasm for the role and the stencil manufacturing industry. Demonstrate your commitment to quality and accuracy, and your willingness to learn and grow.

- Be confident and articulate in your responses.

- Dress professionally and arrive for the interview on time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Stencil Inspector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!