Are you gearing up for a career in Knapsack Sprayer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Knapsack Sprayer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

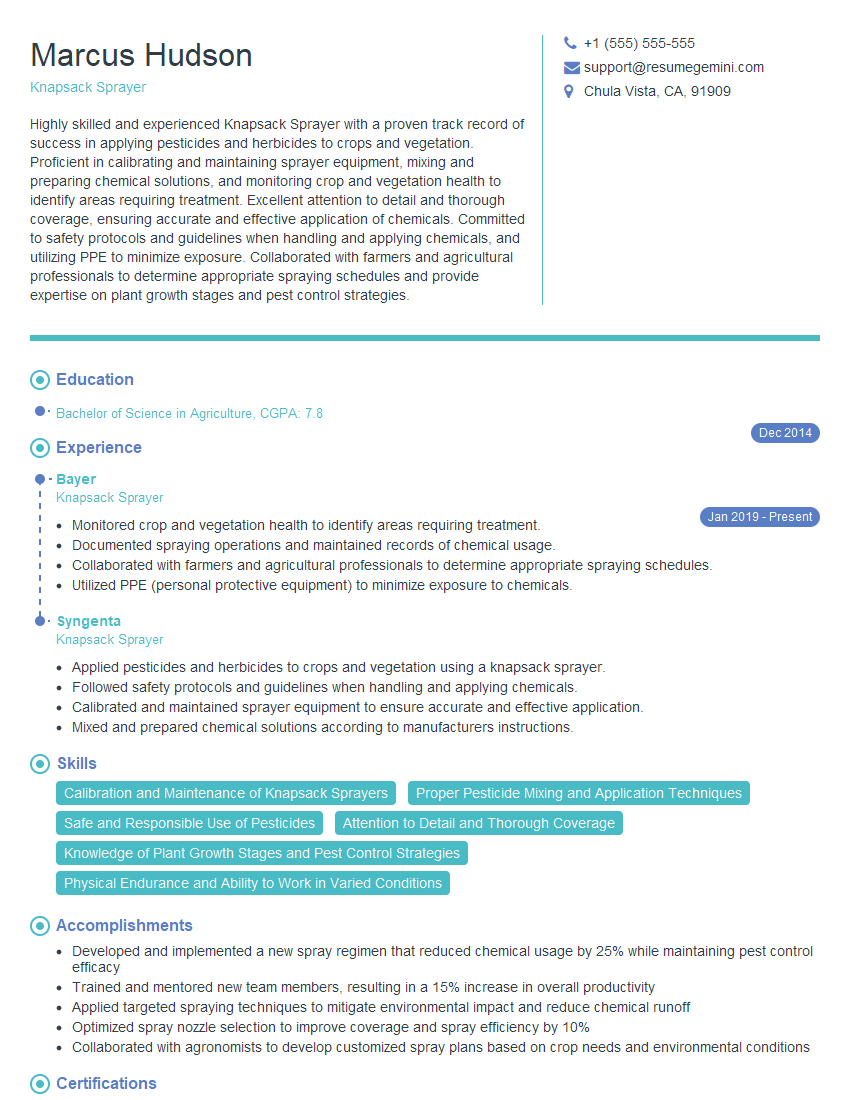

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Knapsack Sprayer

1. Explain the working principle of a knapsack sprayer.

A knapsack sprayer is a portable spraying device used for applying liquid chemicals, such as pesticides, herbicides, and fertilizers, to crops. It consists of a tank, a pump, a hose, and a nozzle. The tank holds the liquid chemical, and the pump pressurizes the liquid and forces it through the hose and out of the nozzle. The nozzle atomizes the liquid into small droplets, which are then dispersed onto the target area.

2. Describe the different types of knapsack sprayers available.

Manual Knapsack Sprayers

- Requires manual pumping to pressurize the liquid.

- Lower cost and more portable.

- Suitable for small areas and occasional use.

Battery-Powered Knapsack Sprayers

- Uses a battery to power the pump.

- Reduces manual effort and provides consistent pressure.

- Suitable for larger areas and frequent use.

Engine-Powered Knapsack Sprayers

- Uses a small engine to power the pump.

- Provides higher pressure and flow rates.

- Suitable for large-scale spraying operations and dense vegetation.

3. What are the factors to consider when choosing a knapsack sprayer?

- Size of the area to be sprayed.

- Frequency of use.

- Type of liquid chemical used.

- Budget and availability.

- Ergonomics and comfort.

4. How do you maintain a knapsack sprayer?

Regular maintenance is essential to ensure the optimal performance and longevity of a knapsack sprayer.

- Clean the tank, hose, and nozzle after each use to prevent clogging and corrosion.

- Inspect the pump, seals, and gaskets for wear or damage.

- Lubricate moving parts according to the manufacturer’s instructions.

- Store the sprayer in a cool, dry place when not in use.

5. What safety precautions should be taken when using a knapsack sprayer?

- Wear appropriate protective clothing, including gloves, mask, and goggles.

- Read the label of the chemical being used and follow all safety instructions.

- Do not spray against the wind or in enclosed areas.

- Avoid contact with the spray mist and do not inhale the fumes.

- Wash hands thoroughly after using the sprayer.

6. How do you troubleshoot common problems with knapsack sprayers?

- Clogged nozzle: Clean or replace the nozzle.

- Leaking pump: Check the seals and gaskets, and replace if necessary.

- Low pressure: Check the pump, hose, and nozzle for obstructions or damage.

- Nozzle dripping: Tighten the nozzle or replace the nozzle tip.

- Sprayer not working: Check the battery or engine, and ensure the chemical tank is filled.

7. Describe the proper technique for spraying with a knapsack sprayer.

- Hold the sprayer upright and keep the nozzle close to the target area.

- Walk at a steady pace while spraying, ensuring even coverage.

- Overlap the spray strokes to avoid missing spots.

- Adjust the spray pattern and pressure as needed for the target area and chemical being used.

8. What is the importance of nozzle selection for a knapsack sprayer?

- Determines the spray pattern, droplet size, and coverage area.

- Affects the efficiency and effectiveness of the spraying operation.

- Consider the target area, liquid chemical, and desired results when selecting a nozzle.

9. Explain the role of the diaphragm in a knapsack sprayer.

- Separates the chemical solution from the pump.

- Creates a seal that prevents leakage and contamination.

- Flexes when the pump operates, allowing the liquid to pass through.

- Requires regular inspection and replacement when worn or damaged.

10. What are the advantages of using a knapsack sprayer with adjustable straps?

- Provides a comfortable and customizable fit for different users.

- Distributes the weight of the sprayer evenly, reducing fatigue.

- Allows for extended spraying sessions without discomfort.

- Helps prevent strain or injury to the user.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Knapsack Sprayer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Knapsack Sprayer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Knapsack Sprayers are crucial in agricultural and pest control operations. The key job responsibilities of a Knapsack Sprayer include:

1. Chemical Preparation and Application

Mixing and preparing pesticides, herbicides, and other chemicals according to prescribed formulas.

Calibrating and operating knapsack sprayers to apply chemicals uniformly and effectively.

2. Pest and Disease Control

Identifying and targeting specific pests or diseases.

Developing and implementing spray programs to control or eradicate infestations.

3. Equipment Maintenance and Inspection

Performing regular inspections and maintenance on knapsack sprayers.

Cleaning and sanitizing equipment to prevent contamination.

4. Safety and Environmental Compliance

Understanding and adhering to all safety regulations related to chemical use and equipment operation.

Following environmental guidelines to minimize the impact of chemical application.

Interview Tips

To ace a job interview for a Knapsack Sprayer position, candidates should consider the following tips:

1. Research and Preparation

Thoroughly research the company and the specific role.

Review industry trends and best practices.

2. Technical Expertise

Highlight your knowledge of chemical handling, application techniques, and sprayer maintenance.

Provide examples of successful pest control or disease management cases.

3. Communication and Interpersonal Skills

Demonstrate clear communication skills, both verbally and in writing.

Show empathy for clients and a willingness to work in a team environment.

4. Safety and Compliance

Emphasize your understanding of safety regulations and environmental compliance.

Describe your commitment to safe practices and environmental preservation.

5. Professionalism and Punctuality

Dress professionally and arrive on time for the interview.

Be polite and respectful to the interviewers.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Knapsack Sprayer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.