Are you gearing up for a career in Weigher and Crusher? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Weigher and Crusher and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

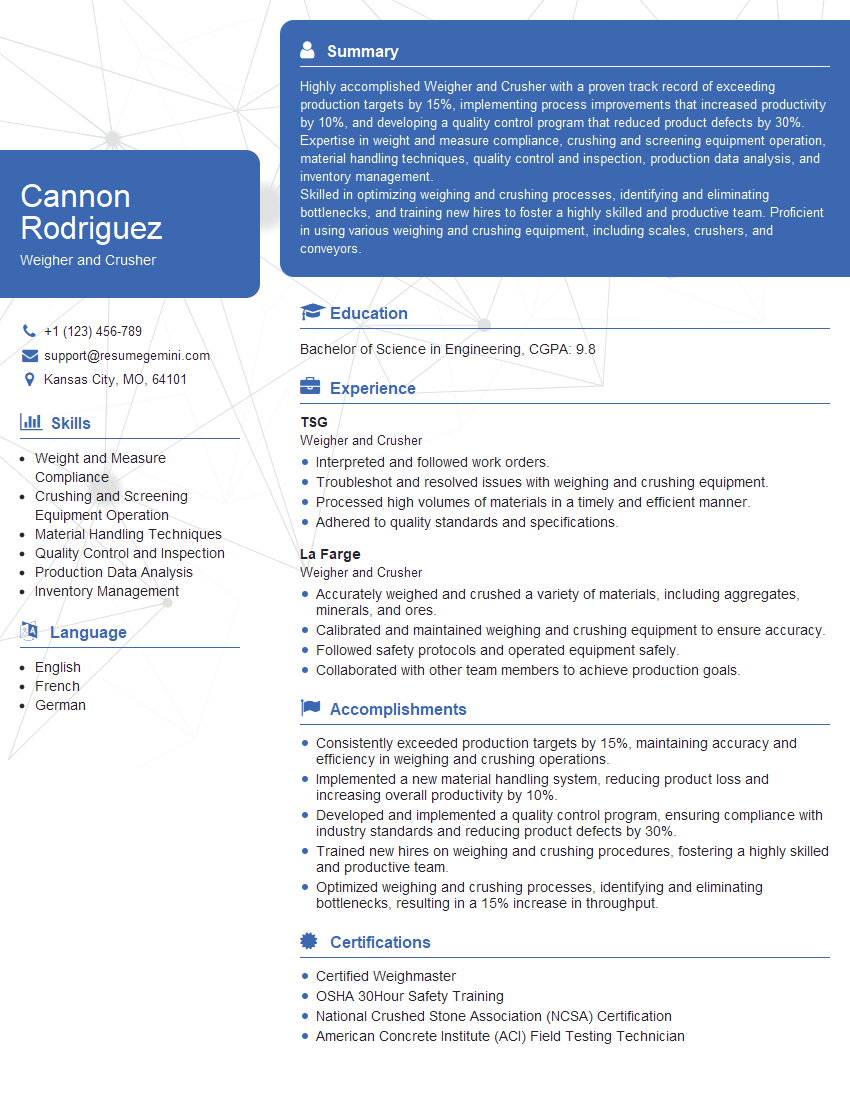

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Weigher and Crusher

1. Explain the process of weighing and crushing materials in your own words.

The process of weighing and crushing materials involves several steps to ensure accurate measurements and efficient processing.

- Weighing: Materials are placed on a scale or balance to determine their mass or weight. This is crucial for accurate inventory management, ensuring proper proportions in mixtures, and calculating costs based on weight.

- Crushing: Materials are subjected to mechanical force to break them down into smaller pieces. This is often necessary to reduce the size of materials for further processing, such as grinding or mixing, or to change their physical properties.

2. Describe the different types of scales used for weighing materials and their applications.

Mechanical Scales

- Beam Scales: Use a beam and weights to measure weight.

- Spring Scales: Use a spring to measure weight.

Electronic Scales

- Digital Scales: Use load cells to convert weight into an electrical signal.

- Platform Scales: Large platforms for weighing heavy objects.

- Crane Scales: Attached to cranes to weigh suspended loads.

3. How do you calibrate and maintain weighing equipment to ensure accuracy?

Calibration is essential to ensure weighing equipment provides accurate measurements. Here are the steps involved:

- Use certified weights to test the scale’s accuracy.

- Adjust the scale’s settings if necessary.

- Document the calibration process and maintain records.

- Regularly inspect and clean weighing equipment to maintain its performance.

4. Describe the different types of crushers and their uses.

Jaw Crushers

- Use two jaws to crush materials.

- Suitable for primary crushing of large materials.

Gyratory Crushers

- Use an eccentric cone to crush materials.

- Used for secondary and tertiary crushing.

Impact Crushers

- Use high-speed impellers to crush materials.

- Suitable for crushing brittle materials.

5. What are the safety precautions that must be observed when operating weighing and crushing equipment?

- Wear appropriate safety gear, including gloves, eye protection, and hearing protection.

- Follow lockout/tagout procedures before performing maintenance or repairs.

- Do not overload equipment or exceed its capacity.

- Inspect equipment regularly for any damage or wear.

- Be aware of pinch points and other potential hazards.

6. How do you troubleshoot common problems that may arise during weighing and crushing operations?

- Inaccurate weighing: Check calibration, inspect load cells, and ensure proper placement of materials.

- Blockages in crushers: Inspect crushers for foreign objects, check feed rates, and adjust crusher settings.

- Overheating: Check lubrication levels, ensure proper ventilation, and reduce feed rates.

- Excessive noise: Check bearings, inspect screens, and balance rotors.

7. Describe the importance of following standard operating procedures (SOPs) when operating weighing and crushing equipment.

- Ensures consistent and accurate operations.

- Minimizes risks and accidents.

- Facilitates training and onboarding of new employees.

- Improves efficiency and productivity.

- Complies with industry regulations and quality standards.

8. Explain how you ensure the quality of materials before and after the weighing and crushing process.

- Before: Inspect materials for contamination, damage, or other defects.

- After: Verify the size, shape, and other specifications of the crushed materials.

- Use quality control measures, such as sampling and testing, to ensure consistency.

9. How do you handle and dispose of waste generated during the weighing and crushing process?

- Identify and segregate waste materials.

- Follow established disposal procedures for hazardous and non-hazardous waste.

- Minimize waste generation through efficient operations and recycling programs.

10. Describe your experience in working with different types of materials and how you adapt your approach to their specific characteristics.

My experience in working with various materials has taught me the importance of adapting my approach to their unique characteristics. For example, when weighing fragile materials, I handle them with utmost care to avoid breakage, while with heavy materials, I prioritize safety and use appropriate lifting equipment. Similarly, when crushing different materials, I adjust the crusher settings and feed rates to achieve the desired size and shape.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Weigher and Crusher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Weigher and Crusher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Weighers and crushers are responsible for weighing, crushing, and preparing materials for further processing in various industries, such as mining, manufacturing, and waste management.

1. Weighing and Crushing Materials

Key responsibilities include:

- Accurately weighing and measuring incoming materials, such as ores, minerals, and scrap metal

- Operating crushing equipment, such as jaw crushers, impact crushers, and cone crushers, to reduce the size of materials

- Ensuring that materials meet specified weight, size, and quality standards

2. Material Handling

Weighers and crushers also handle materials, including:

- Loading and unloading materials from trucks, conveyors, and storage bins

- Storing and transporting materials within the facility

- Maintaining and cleaning equipment and work areas

3. Quality Control

Weighers and crushers play a crucial role in quality control, as they ensure that materials meet the required specifications. Responsibilities include:

- Monitoring and inspecting materials during processing

- Taking corrective actions to address any quality issues

- Maintaining accurate records of weighing and crushing operations

4. Compliance and Safety

Weighers and crushers must comply with all applicable laws and regulations, as well as company policies and procedures. They also play a key role in maintaining a safe work environment, including:

- Following all safety protocols and procedures

- Identifying and reporting potential hazards

- Wearing appropriate personal protective equipment (PPE)

Interview Tips

To ace an interview for a Weigher and Crusher position, candidates should prepare thoroughly and demonstrate their skills and knowledge.

1. Research the Company and Position

Familiarize yourself with the company’s background, its industry, and the specific role you are applying for. Research the company’s website, LinkedIn profile, and any relevant news articles.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in weighing, crushing, and handling materials. Quantify your accomplishments whenever possible, using specific examples.

3. Prepare for Technical Questions

Expect questions about your knowledge of weighing and crushing equipment, material handling techniques, and quality control procedures.

4. Showcase Your Safety and Compliance Awareness

Demonstrate your understanding of safety protocols, your commitment to compliance, and your ability to work safely in a potentially hazardous environment.

5. Practice Your Answers

Prepare and practice your answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this role?” and “What are your strengths and weaknesses?”

6. Anticipate Behavioral Questions

Be ready to answer behavioral questions using the STAR method (Situation, Task, Action, Result). For example, you might be asked to describe a time when you had to troubleshoot a problem with a crushing machine.

7. Ask Informed Questions

Ask thoughtful questions during the interview to show your interest and engagement. This could include questions about the company’s growth plans, its commitment to sustainability, or its training and development opportunities.

8. Dress Professionally

First impressions matter, so dress appropriately for the interview. Choose clean, pressed clothing that is suitable for the company’s culture.

9. Be Punctual and Polite

Punctuality and politeness show respect for the interviewer’s time and your own professionalism.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Weigher and Crusher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!