Are you gearing up for an interview for a Weigher and Grader position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Weigher and Grader and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

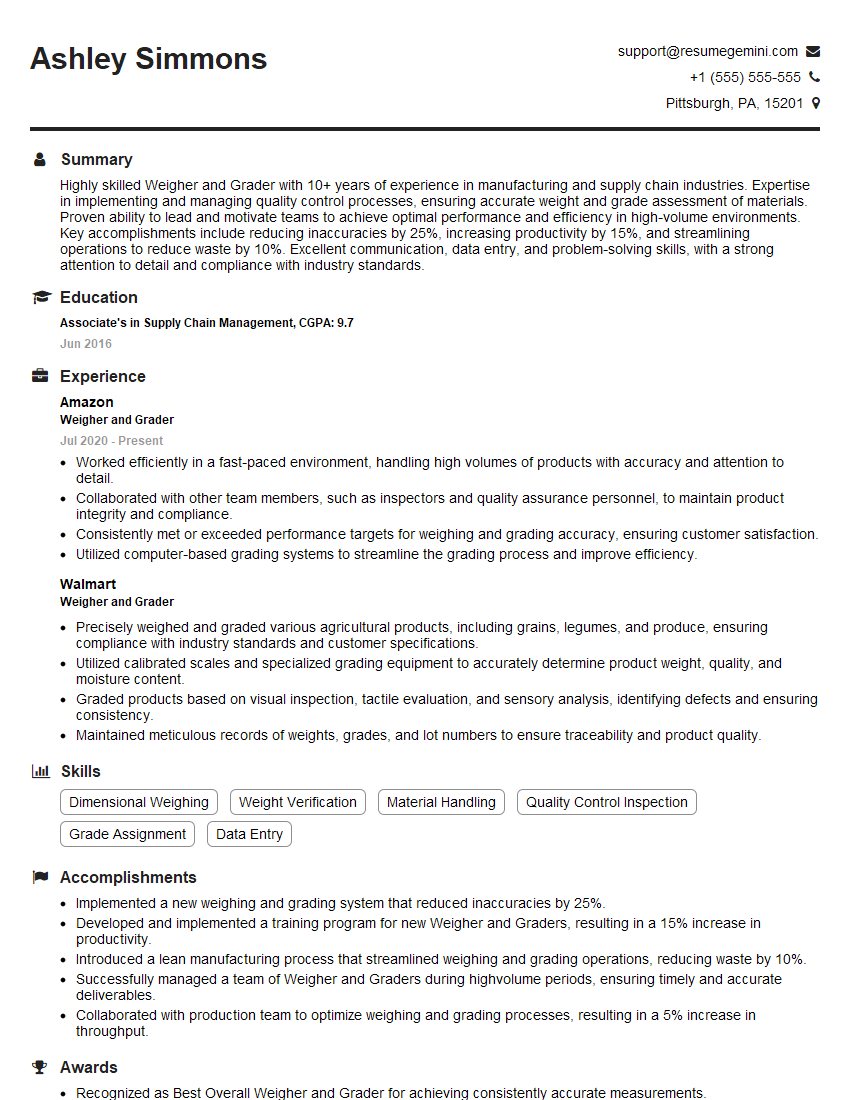

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Weigher and Grader

1. Can you explain the process of weighing and grading products?

In the weighing process, I use a scale to determine the weight of products. I ensure accuracy by calibrating the scale regularly and following established procedures to obtain precise measurements. As for grading, I assess the quality of products based on predetermined criteria. This involves examining products for defects, size, color, and other relevant factors to determine their grade.

2. What are the different types of weighing and grading equipment and their uses?

Weighing Equipment

Beam scales:

Used for precise weighing of small quantities.Digital scales:

Provide accurate weight measurements for various capacities.Truck scales:

Designed to weigh heavy vehicles and their loads.

Grading Equipment

Grading machines:

Automated systems that sort products based on size, weight, and quality.Optical sorters:

Use cameras and sensors to detect defects and impurities.Manual grading stations:

Where products are inspected and graded by trained personnel.

3. How do you ensure the accuracy and reliability of your weighing and grading results?

- Regular calibration of weighing equipment.

- Following established grading criteria and procedures.

- Performing regular checks to monitor accuracy and consistency.

- Seeking feedback from supervisors or quality control personnel.

4. What are the safety precautions to consider when weighing and grading products?

- Proper handling of heavy equipment to prevent injuries.

- Use of appropriate personal protective equipment (PPE) such as gloves and safety glasses.

- Maintaining a clean and organized work area to minimize hazards.

- Following established safety protocols and reporting any potential safety concerns.

5. How do you prioritize and manage your workload when there are multiple tasks to complete?

- Assessing the urgency and importance of each task.

- Prioritizing tasks based on deadlines and dependencies.

- Delegating tasks to other team members when necessary.

- Communicating with supervisors to adjust priorities as needed.

6. Can you describe a situation where you faced a challenge in weighing or grading products and how you resolved it?

In a previous role, I encountered a malfunctioning digital scale that was providing inaccurate weight measurements. I promptly reported the issue to my supervisor and worked with the maintenance team to troubleshoot the problem. We identified a faulty sensor and replaced it, ensuring the accuracy of the scale and maintaining the quality of our products.

7. What is your understanding of quality assurance and quality control processes in weighing and grading?

- Quality assurance: Implementing measures to prevent defects and ensure product quality.

- Quality control: Monitoring and inspecting products to identify and correct any non-conformities.

- Understanding the importance of following established standards and procedures.

8. Can you explain the different grading scales and how they are used in the industry?

- Numerical grades: Assigning numbers to indicate product quality.

- Letter grades: Using letters (e.g., A, B, C) to represent quality levels.

- Descriptive grades: Providing detailed descriptions of product attributes.

- Understanding the specific grading scale used in the industry and applying it consistently.

9. How do you handle discrepancies or errors in your weighing or grading results?

- Verifying the results and identifying the source of the error.

- Documenting the discrepancy and reporting it to supervisors.

- Taking corrective actions to prevent similar errors in the future.

10. Are you familiar with any industry-specific regulations or standards related to weighing and grading?

- Awareness of relevant regulations and standards (e.g., ISO 9001, HACCP).

- Understanding the importance of adhering to these regulations to ensure product safety and quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Weigher and Grader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Weigher and Grader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The role of Weigher and Grader involves a range of responsibilities crucial to maintaining product quality and ensuring accurate weight and grade measurements. Here are the key job responsibilities:1. Weighing and Grading Products

Weighers and Graders are primarily responsible for accurately weighing and grading products using scales, gauges, and other measuring devices. They compare the weight and quality of products against established specifications and determine the appropriate grade, size, or category.

2. Inspecting and Sorting Products

They thoroughly inspect products for any defects, damages, or inconsistencies. This includes visually examining products, checking for contamination, and ensuring they meet the required quality standards. Based on the inspection, they sort products into different grades or categories.

3. Recording and Maintaining Data

Weighers and Graders meticulously record and maintain data related to the weight, grade, and quantity of products handled. They keep accurate records of their findings, which are essential for inventory control, quality assurance, and traceability.

4. Maintaining Equipment and Work Area

To ensure accuracy and efficiency, Weighers and Graders are responsible for maintaining and calibrating the weighing and grading equipment they use. They also maintain a clean and organized work area to prevent contamination and accidents.

5. Adhering to Safety Regulations

They follow established safety regulations and protocols to ensure a safe working environment. This includes wearing appropriate protective gear, handling products safely, and reporting any potential hazards or concerns.

Interview Tips

To help candidates ace the interview for the Weigher and Grader position, here are some essential tips and preparation hacks:1. Research the Company and Position

Before the interview, thoroughly research the company and the specific Weigher and Grader position you are applying for. Understand the company’s products, industry, and culture to demonstrate your interest and alignment with their values.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience in weighing and grading products, as well as your attention to detail and accuracy. Quantify your accomplishments whenever possible to showcase your impact. For example, you could mention the number of products you have weighed and graded within a specific time frame or the percentage of products that met or exceeded quality standards under your supervision.

3. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers beforehand. Anticipate questions about your experience in weighing and grading, your knowledge of quality standards, and your ability to work independently and as part of a team. Practice delivering clear and concise responses that demonstrate your skills and enthusiasm for the role.

4. Ask Thoughtful Questions

During the interview, ask thoughtful questions to show your engagement and interest in the position. This could include questions about the company’s quality control processes, the career advancement opportunities within the organization, or the training and support provided to Weighers and Graders.

5. Dress Professionally and Arrive On Time

First impressions matter, so dress professionally and arrive punctually for your interview. Maintain a positive and confident demeanor throughout the interview, and thank the interviewer for their time and consideration.

By following these tips and preparing thoroughly, candidates can increase their chances of impressing the interviewer and landing the Weigher and Grader position.Next Step:

Now that you’re armed with the knowledge of Weigher and Grader interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Weigher and Grader positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini