Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Webbing Inspector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Webbing Inspector so you can tailor your answers to impress potential employers.

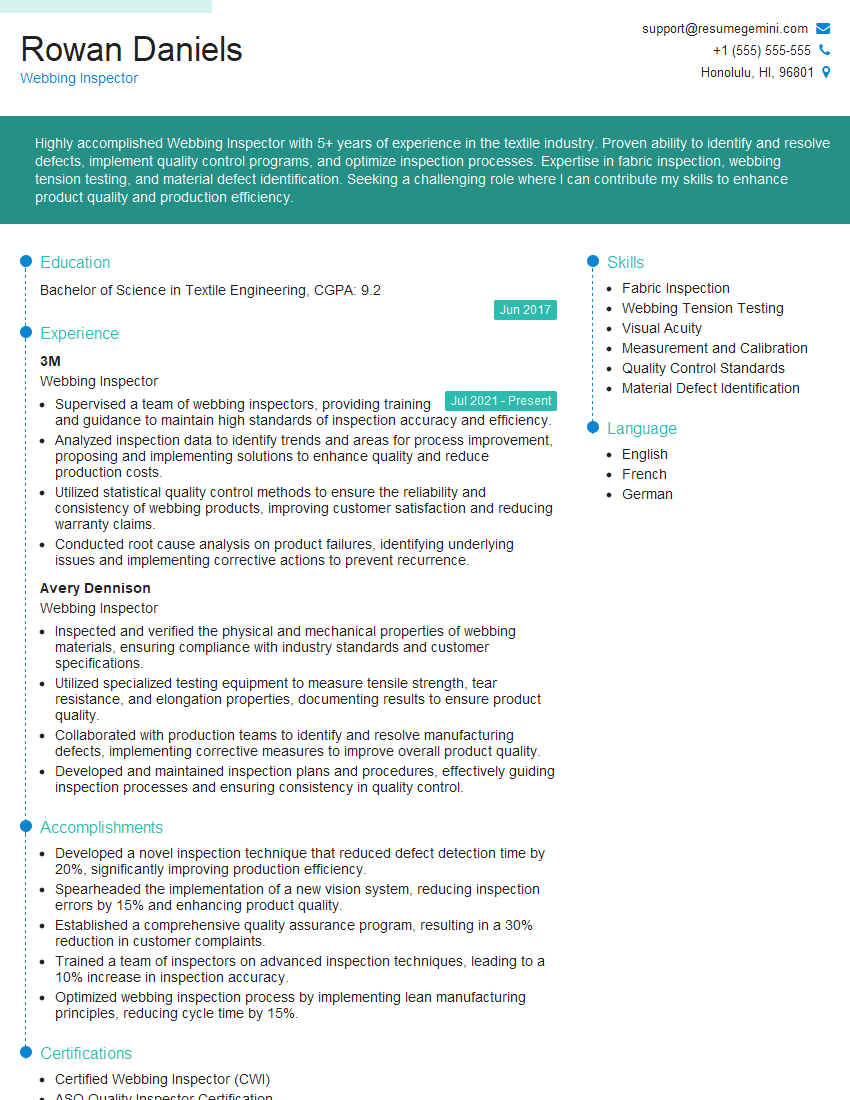

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Webbing Inspector

1. Describe the key responsibilities of a Webbing Inspector?

As a Webbing Inspector, my core responsibilities revolve around ensuring the quality and compliance of webbing materials used in various applications such as automotive seat belts, cargo straps, and industrial lifting slings.

- Inspecting webbing samples to verify their conformance to specifications, including width, thickness, color, weave, and strength.

- Conducting laboratory testing to assess webbing properties such as breaking strength, elongation, and abrasion resistance.

- Evaluating webbing performance in real-world applications and providing recommendations for improvement.

- Maintaining detailed inspection reports and records for quality control purposes.

- Collaborating with webbing manufacturers, suppliers, and end-users to address quality concerns and ensure product safety.

2. What are the different types of webbing materials you are familiar with?

Natural Fibers

- Cotton

- Polyester

- Nylon

Synthetic Fibers

- Kevlar

- Spectra

- Dyneema

3. What are the common defects you look for during webbing inspection?

During webbing inspection, I pay close attention to various potential defects that may affect the quality and safety of the material.

- Broken or missing yarns

- Holes or tears in the webbing

- Uneven weave or tension

- Color variations or fading

- Presence of contamination or foreign objects

4. How do you determine the strength and durability of webbing materials?

I employ various laboratory testing methods to assess the strength and durability of webbing materials.

- Breaking Strength Test: Measures the force required to break the webbing under controlled conditions.

- Elongation Test: Evaluates the amount of stretch or deformation the webbing undergoes before breaking.

- Abrasion Resistance Test: Determines the material’s resistance to wear and tear caused by repeated friction.

5. What are some industry standards or regulations that apply to webbing inspection?

In my role, I adhere to a range of industry standards and regulations to ensure the safety and quality of webbing materials.

- ASTM International (ASTM) standards

- American National Standards Institute (ANSI) standards

- Occupational Safety and Health Administration (OSHA) regulations

- International Organization for Standardization (ISO) standards

6. How do you stay updated on the latest webbing inspection techniques and technologies?

To stay abreast of advancements in webbing inspection practices, I engage in continuous professional development.

- Attending industry conferences and webinars

- Reading technical journals and publications

- Participating in online forums and discussion groups

- Consulting with experts and peers in the field

7. Describe a situation where you identified a critical defect in a webbing sample and how you handled it?

In one instance, I identified a subtle but critical defect in a webbing sample intended for use in automotive seat belts. The defect, if unnoticed, could have compromised the safety of the seat belt in the event of an accident.

- Prompted immediate notification of the manufacturer and end-user.

- Issued a detailed inspection report highlighting the defect and its potential consequences.

- Worked with the manufacturer to determine the root cause and implement corrective actions.

- Collaborated with the end-user to ensure the affected seat belts were removed from service and replaced.

8. What software or tools do you use to conduct webbing inspections?

I utilize a combination of manual inspection techniques and advanced software tools to ensure thorough and accurate webbing inspections.

- Microscope: For examining fine details and identifying defects.

- Digital Calipers: For precise measurements of webbing dimensions.

- Tensile Testing Machine: For evaluating breaking strength and elongation.

- Webbing Inspection Software: For automated analysis and defect detection.

9. How do you prioritize inspection tasks when you have multiple samples to examine?

When faced with a high volume of webbing samples, I prioritize inspections based on several key factors.

- Urgency: Prioritizing samples intended for critical applications or with tight deadlines.

- Risk: Considering the potential safety or quality risks associated with the webbing’s intended use.

- Sample Size: Managing the workload by inspecting smaller samples first and allocating more time for larger ones.

- Customer Requirements: Adhering to specific inspection criteria or turnaround times requested by clients.

10. How do you ensure the accuracy and reliability of your inspection results?

To maintain the accuracy and reliability of my inspection results, I follow several best practices.

- Calibration: Regularly calibrating inspection equipment and tools.

- Standardization: Adhering to established inspection procedures and methodologies.

- Peer Review: Seeking second opinions or cross-checking results with colleagues.

- Training and Certification: Maintaining up-to-date industry certifications and attending relevant training programs.

- Quality Control: Implementing quality control measures within the inspection process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Webbing Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Webbing Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Webbing Inspectors play a crucial role in ensuring the quality and safety of webbing products by thoroughly scrutinizing and measuring them.

1. Inspecting Webbing for Defects

They meticulously examine webbing for defects, including stains, tears, holes, or any irregularities that could compromise its quality.

- Utilizing visual inspection techniques to detect flaws

- Employing measuring tools to verify dimensions and ensure compliance with specifications

2. Assessing Webbing Strength and Durability

They evaluate the strength and durability of webbing by conducting various tests.

- Performing tensile strength tests to determine the webbing’s resistance to breaking

- Conducting abrasion resistance tests to assess its ability to withstand wear and tear

- Measuring elongation and recovery properties to ensure it meets elasticity requirements

3. Maintaining Inspection Equipment

They are responsible for maintaining the accuracy and functionality of inspection equipment.

- Calibrating and maintaining measuring instruments

- Performing regular maintenance checks to ensure optimal performance

4. Documenting Inspection Results

They meticulously document the results of inspections to ensure traceability and maintain quality records.

- Creating detailed inspection reports

- Maintaining inspection logs and databases

Interview Tips

Preparing for a Webbing Inspector interview requires thorough research and practice.

1. Research the Company and Industry

Familiarize yourself with the company’s products, market position, and industry trends.

- Visit the company website and social media pages

- Read industry publications and articles

2. Practice Answering Common Interview Questions

Prepare your responses to common interview questions, such as:

- Tell me about your experience in webbing inspection.

- How do you ensure the accuracy of your inspections?

- What are the key quality standards for webbing?

3. Highlight Your Skills and Experience

Emphasize your skills in visual inspection, measurement techniques, and quality assurance.

- Quantify your accomplishments using specific examples.

- Demonstrate your attention to detail and commitment to quality.

4. Prepare Questions for the Interviewer

Asking thoughtful questions shows your engagement and interest in the role.

- Inquire about the company’s quality control processes

- Ask about the specific responsibilities of the Webbing Inspector position

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Webbing Inspector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!