Feeling lost in a sea of interview questions? Landed that dream interview for Wheel Inspector but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Wheel Inspector interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

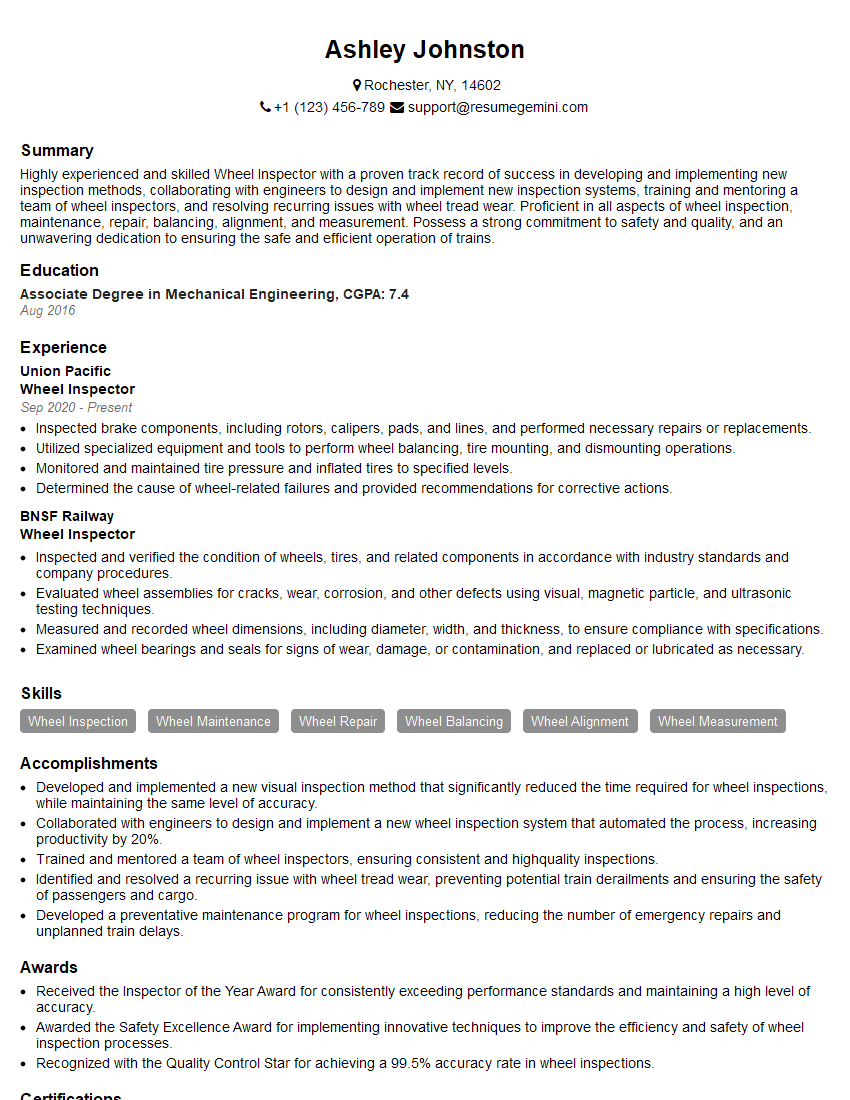

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wheel Inspector

1. Explain the process of wheel inspection?

- Inspect the wheel for any visible damage or defects, such as cracks, dents, or scratches.

- Check the tire pressure and ensure it meets the manufacturer’s specifications.

- Examine the wheel bearings for any signs of wear or damage.

- Inspect the brake pads and rotors for any excessive wear or damage.

- Check the lug nuts to ensure they are properly tightened.

2. What are the common types of wheel defects that you look for during an inspection?

Cracks

- Radial cracks: Cracks that run from the rim to the center of the wheel.

- Circumferential cracks: Cracks that run around the circumference of the wheel.

Dents

- Minor dents: Dents that do not affect the structural integrity of the wheel.

- Major dents: Dents that compromise the structural integrity of the wheel and require repair or replacement.

Scratches

- Minor scratches: Scratches that do not affect the performance of the wheel.

- Major scratches: Scratches that compromise the structural integrity of the wheel and require repair or replacement.

3. What equipment do you use to perform wheel inspections?

- Wheel inspection gauge

- Tire pressure gauge

- Lug wrench

- Flashlight

- Safety glasses

4. What are the safety precautions that you take when performing wheel inspections?

- Wear appropriate safety gear, including safety glasses and gloves.

- Park the vehicle on a level surface and engage the parking brake.

- Chock the wheels opposite the wheels being inspected.

- Never inspect a wheel while the vehicle is in motion.

- Use proper lifting equipment to raise the vehicle.

5. How do you determine if a wheel is safe to use?

- The wheel is free of any visible damage or defects.

- The tire pressure is within the manufacturer’s specifications.

- The wheel bearings are in good condition and free of any excessive play.

- The brake pads and rotors are in good condition and free of any excessive wear or damage.

- The lug nuts are properly tightened.

6. What are the consequences of not inspecting wheels regularly?

- Increased risk of accidents due to wheel failure.

- Reduced fuel efficiency due to improper tire pressure.

- Premature wear and tear on other components, such as brakes and suspension.

- Increased maintenance costs.

7. What are the different types of wheel alignments?

- Toe alignment: Adjusts the angle of the wheels so that they are parallel to each other.

- Camber alignment: Adjusts the angle of the wheels so that they are perpendicular to the ground.

- Caster alignment: Adjusts the angle of the steering axis.

8. What are the benefits of regular wheel alignments?

- Improved handling and stability.

- Reduced tire wear.

- Improved fuel efficiency.

- Extended lifespan of suspension components.

9. How often should wheels be aligned?

- Every 6 months to 1 year, or as recommended by the vehicle manufacturer.

- After any major repairs or modifications to the suspension.

- After hitting a curb or pothole.

10. What are the signs that a vehicle needs a wheel alignment?

- Uneven tire wear.

- Vehicle pulling to one side when driving.

- Steering wheel vibration.

- Difficulty steering.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wheel Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wheel Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wheel Inspectors are responsible for ensuring that wheels meet safety and performance standards. Their key responsibilities include:

1. Identifying Wheel Defects

Inspecting wheels for defects such as cracks, dents, and rust.

- Using specialized equipment to detect hidden defects.

- Classifying defects based on severity and determining if repairs are necessary.

2. Evaluating Wheel Performance

Conducting tests to assess wheel strength, durability, and balance.

- Using testing equipment to measure wheel properties.

- Analyzing test results to determine if wheels meet specifications.

3. Maintaining Records and Documentation

Keeping accurate records of inspections, tests, and repairs.

- Completing inspection forms and reports.

- Filing and organizing documentation related to wheel inspections and repairs.

4. Implementing Safety Procedures

Ensuring that all safety protocols are followed during inspections and repairs.

- Training colleagues on safety procedures.

- Reporting safety hazards and implementing corrective actions.

Interview Tips

Preparing for a Wheel Inspector interview requires research, practice, and confidence. Here are some tips to help you ace the interview:

1. Research the Company

Learn about the company’s values, mission, and products. This will help you tailor your answers to the specific role and demonstrate your interest in the company.

- Visit the company website and social media pages.

- Read news articles and industry publications about the company.

2. Practice Your Answers

Prepare thoughtful responses to common interview questions. Practice your delivery and ensure your answers are clear, concise, and relevant to the job responsibilities.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Seek feedback from friends, family, or mentors on your practice sessions.

3. Highlight Relevant Skills and Experience

Emphasize your skills and experience that align with the key job responsibilities of a Wheel Inspector. Use specific examples to demonstrate your competence.

- Highlight your knowledge of wheel inspection techniques and equipment.

- Share examples of successful wheel inspections and repairs you have conducted.

4. Be Enthusiastic and Professional

During the interview, maintain a positive and professional demeanor. Show your enthusiasm for the role and convey your eagerness to learn and contribute.

- Dress appropriately and arrive on time for the interview.

- Be respectful and courteous to the interviewer and other staff.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wheel Inspector interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.