Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Wheel and Pinion Inspector position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

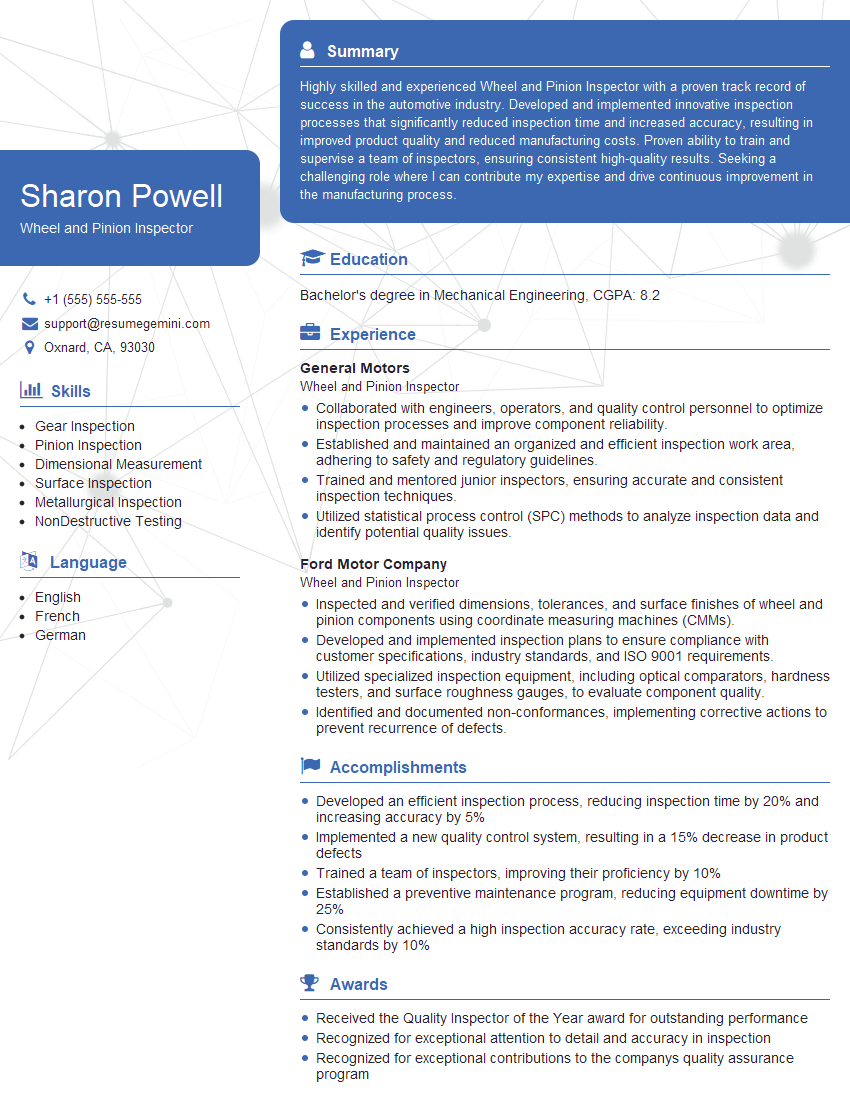

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wheel and Pinion Inspector

1. What are the key responsibilities of a Wheel and Pinion Inspector?

- Inspect wheels and pinions for defects such as cracks, burrs, and wear

- Verify dimensions and tolerances using precision measuring equipment

- Ensure that wheels and pinions meet specifications and standards

- Maintain inspection records and report any non-conformances

- Troubleshoot and resolve issues related to wheel and pinion quality

2. What types of inspection equipment do you have experience using?

Precision Measuring Equipment

- Calipers

- Micrometers

- Coordinate measuring machines (CMMs)

Non-Destructive Testing Equipment

- Eddy current testing

- Ultrasonic testing

- Magnetic particle inspection

3. How do you interpret and apply inspection specifications and standards?

- Review specifications and standards to understand the requirements for wheels and pinions

- Select appropriate inspection equipment and techniques based on the specifications

- Compare inspection results to the specified tolerances and dimensions

- Identify any non-conformances and determine the appropriate corrective action

4. What is your process for troubleshooting and resolving issues related to wheel and pinion quality?

- Identify the source of the issue by analyzing inspection data and examining the wheels and pinions

- Determine the root cause of the issue by considering factors such as manufacturing processes, material properties, and design

- Develop and implement corrective actions to address the root cause and prevent recurrence

- Monitor the effectiveness of corrective actions and make adjustments as necessary

5. What is your understanding of the different types of defects that can occur in wheels and pinions?

- Cracks: Can occur due to stress, fatigue, or improper heat treatment

- Burrs: Raised edges that can result from machining or grinding operations

- Wear: Gradual loss of material due to friction, abrasion, or corrosion

- Dimensional errors: Deviations from the specified dimensions, such as out-of-roundness or taper

- Surface defects: Imperfections on the surface of the wheels or pinions, such as pitting or scratches

6. How do you ensure the accuracy and reliability of your inspections?

- Calibrate inspection equipment regularly to ensure precision

- Follow established inspection procedures and checklists

- Conduct thorough and systematic inspections

- Review inspection results with a supervisor or other qualified personnel

- Maintain documentation of all inspections and corrective actions

7. What are the most common causes of wheel and pinion failures?

- Overloading: Operating wheels and pinions beyond their rated capacity

- Improper installation: Incorrect alignment, insufficient lubrication, or excessive tightening

- Manufacturing defects: Defects in materials, machining, or heat treatment

- Wear and tear: Gradual degradation of components due to friction and stress

- Corrosion: Chemical reactions that weaken the material

8. How do you stay up-to-date with the latest inspection techniques and standards?

- Attend industry conferences and training programs

- Read technical publications and research papers

- Network with other inspectors and quality control professionals

- Participate in continuing education programs

- Obtain industry certifications

9. What is your experience with using statistical process control (SPC) techniques?

- Collected and analyzed inspection data

- Created control charts to monitor and analyze process performance

- Identified trends and patterns in the data

- Made adjustments to the inspection process to improve accuracy and reliability

- Reported on the effectiveness of SPC techniques

10. How do you handle situations where you identify a non-conforming wheel or pinion?

- Isolate the non-conforming item to prevent it from being used

- Document the non-conformance and notify the appropriate personnel

- Determine the cause of the non-conformance and implement corrective actions

- Retest the item to verify that the corrective actions were effective

- Dispose of or rework the non-conforming item if necessary

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wheel and Pinion Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wheel and Pinion Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wheel and Pinion Inspectors play a critical role in ensuring the quality and precision of automotive components. Their key responsibilities include:

1. Inspection and Testing

Meticulously inspecting wheels and pinions using specialized equipment to identify defects, wear, and dimensional deviations.

- Using precision measuring tools (e.g., calipers, micrometers) to check dimensions and tolerances.

- Conducting visual inspections to detect surface imperfections, cracks, and other anomalies.

- Operating testing machines to assess the functionality and performance of wheels and pinions under controlled conditions.

2. Quality Control

Monitoring and maintaining quality standards throughout the inspection process.

- Adhering to established inspection criteria and specifications.

- Documenting inspection results and providing detailed reports.

- Identifying and segregating defective parts to prevent their use in production.

3. Process Improvement

Collaborating with production teams to identify and implement process improvements that enhance efficiency and quality.

- Analyzing inspection data to identify trends and areas for improvement.

- Suggesting modifications to inspection techniques, equipment, or workflows.

- Providing training and guidance to other inspectors to maintain consistency and accuracy.

4. Safety and Compliance

Ensuring adherence to safety protocols and industry regulations.

- Properly using and maintaining inspection equipment.

- Following safety guidelines to minimize risks.

- Complying with environmental and quality management standards.

Interview Tips

To ace the interview for a Wheel and Pinion Inspector position, candidates should thoroughly prepare and consider the following tips:

1. Research the Company and Position

Demonstrate your interest and understanding of the company’s operations, the specific job requirements, and the industry.

- Visit the company’s website, read industry publications, and connect with professionals in the field.

- Identify key responsibilities and qualifications listed in the job description, and highlight your relevant skills and experience.

2. Practice Your Technical Skills

Be prepared to discuss your proficiency in using inspection equipment, measuring tools, and testing procedures.

- Review your notes from previous training or certification courses.

- Practice using the specific equipment and techniques that may be used in the role.

- Be able to explain your approach to inspecting and testing wheels and pinions.

3. Emphasize Quality and Attention to Detail

Stress your commitment to maintaining high quality standards and your ability to identify and address defects accurately.

- Provide examples of your previous experience in quality control or inspection roles.

- Highlight your meticulous nature and your ability to follow instructions precisely.

- Describe your understanding of the importance of accuracy and precision in this field.

4. Showcase Your Problem-Solving Skills

Demonstrate your ability to analyze inspection data, identify root causes of problems, and develop solutions to improve processes.

- Share examples of how you have used data analysis to identify trends and make recommendations for improvement.

- Explain your approach to troubleshooting and resolving technical issues.

- Discuss your willingness to collaborate with production teams to enhance efficiency and quality.

5. Be Enthusiastic and Professional

Convey your passion for the job and your commitment to the company’s success.

- Be polite, respectful, and engaged during the interview.

- Ask thoughtful questions about the role and the company’s goals.

- Thank the interviewers for their time and consideration.

Next Step:

Now that you’re armed with the knowledge of Wheel and Pinion Inspector interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Wheel and Pinion Inspector positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini