Are you gearing up for an interview for a Wood Inspector position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Wood Inspector and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

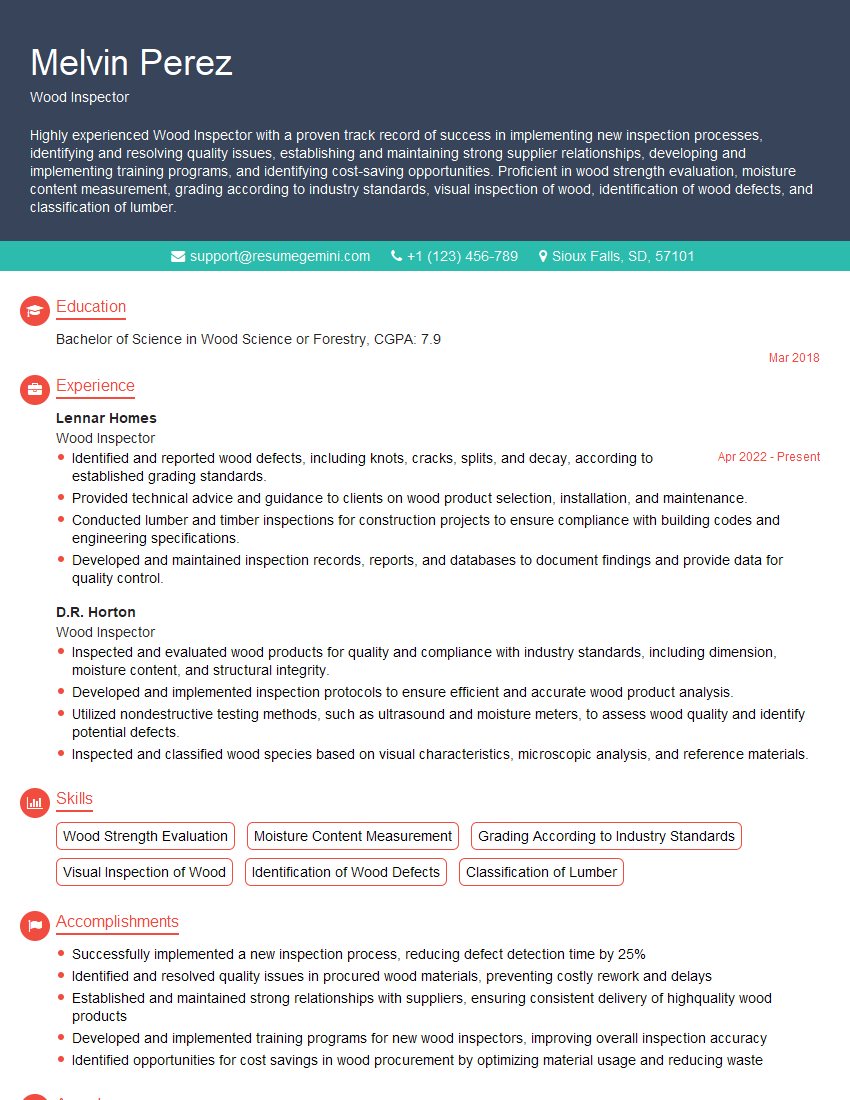

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wood Inspector

1. Explain the different grades of lumber and how they are determined?

Grade:

- Select: Clear of knots and imperfections, used for high-end furniture and cabinetry.

- Common: May contain knots and imperfections, used for framing and construction.

- Utility: Low-grade lumber with significant imperfections, used for crating and other non-structural applications.

- Stud: Specifically graded for use in wall studs.

Factors Determining Grade:

- Knot size and frequency

- Warp, twist, and bow

- Presence of decay, stain, or other defects

- Grain orientation and texture

2. What are the key characteristics of different wood species and how do they affect their use?

Strength and Durability:

- Oak: Strong, durable, and resistant to decay.

- Maple: Hard and strong, with good wear resistance.

- Pine: Soft, lightweight, and easy to work with.

Grain and Texture:

- Mahogany: Fine grain with a reddish-brown color.

- Cherry: Close-grained with a rich, warm tone.

- Walnut: Dark, rich grain with a distinctive figure.

3. Describe the process for inspecting lumber for defects and damage.

Visual Inspection:

- Check for knots, splits, cracks, and other surface imperfections.

- Examine the grain orientation and texture for signs of warping or twisting.

Probe Test:

- Use a probe to detect internal defects, such as rot or decay.

- Probe into knots and other suspicious areas to assess their depth and severity.

Moisture Meter Test:

- Measure the moisture content of the wood to ensure that it is within acceptable limits.

- High moisture content can indicate potential for decay or warping.

4. How do you determine the moisture content of wood using a moisture meter?

- Calibrate the moisture meter according to manufacturer’s instructions.

- Insert the probes into the wood to a specified depth.

- Read the moisture content value displayed on the meter.

- Compare the reading to acceptable moisture content levels for the intended use of the wood.

5. What are the common causes of wood decay and how can it be prevented?

Causes of Wood Decay:

- Moisture: Excess moisture provides a conducive environment for decay fungi.

- Oxygen: Decay fungi require oxygen to grow and spread.

- Nutrients: Wood contains nutrients that support fungal growth.

Prevention of Wood Decay:

- Keep wood dry and well-ventilated.

- Apply protective coatings or sealants to prevent moisture penetration.

- Use pressure-treated lumber in areas exposed to moisture.

6. Explain the difference between dry rot and wet rot and how to identify them.

Dry Rot:

- Caused by fungi that require a moisture content below 20%.

- Produces a crumbly, brown or reddish-brown decay.

- Common in structural timbers in dry conditions.

Wet Rot:

- Caused by fungi that require a moisture content above 20%.

- Produces a soft, spongy, and discolored decay.

- Common in areas exposed to heavy moisture, such as basements and bathrooms.

7. What are the different types of wood preservatives and how are they applied?

Types of Wood Preservatives:

- Oil-based: Penetrates deeply into the wood and provides excellent protection against rot and decay.

- Water-based: Less penetrating but easier to apply.

- Borate-based: Environmentally friendly and effective against termites and carpenter ants.

Methods of Application:

- Brushing or spraying: For surface application or small areas.

- Dipping: For treating entire pieces of lumber or timber.

- Pressure treatment: Forces preservative deep into the wood under high pressure.

8. What are the safety precautions that should be taken when working with wood preservatives?

- Wear protective gear, including gloves, eye protection, and a respirator.

- Work in a well-ventilated area.

- Follow manufacturer’s instructions for application and disposal.

- Store preservatives in a secure location away from children and pets.

9. Explain the importance of proper storage and handling of lumber to prevent defects and damage.

- Moisture Control: Store lumber in a dry, well-ventilated area to prevent warping and twisting.

- Stacking: Stack lumber on flat surfaces with spacers to allow air circulation.

- Protection from Elements: Cover lumber with tarps or plastic to protect from rain, snow, and sun.

- Regular Inspections: Check lumber regularly for signs of defects, damage, or moisture problems.

10. Describe the procedures for documenting and reporting lumber defects and damage to stakeholders.

- Create a detailed report: Include information on the type and severity of defects, location, and any potential impact.

- Take photographs: Capture clear images of the defects to provide visual evidence.

- Notify relevant parties: Inform project managers, contractors, and suppliers of the defects and any necessary corrective actions.

- Maintain records: Keep documentation of all inspections and reports for future reference and accountability.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wood Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wood Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wood Inspectors are responsible for ensuring that wood products meet the required specifications. They examine wood for defects, such as knots, cracks, and decay, and determine whether the wood is suitable for use in construction or other applications.

1. Inspects wood products to ensure that they meet specifications

Wood Inspectors visually inspect wood products, such as lumber, plywood, and veneer, to identify any defects. They use a variety of tools, such as a magnifying glass, to examine the wood for knots, cracks, splits, decay, and other imperfections. They also measure the wood to ensure that it meets the specified dimensions.

2. Grades wood products according to their quality

Wood Inspectors grade wood products based on their quality. The grade of wood is determined by the number and severity of the defects present. Wood Inspectors use a variety of grading systems, such as the American Lumber Standard (ALS) grading system, to determine the grade of wood.

3. Certifies wood products as meeting specifications

Wood Inspectors certify wood products as meeting specifications by issuing a certificate of inspection. The certificate of inspection states that the wood products have been inspected and meet the specified requirements. Wood Inspectors may also issue a grading certificate, which states the grade of the wood products.

4. Maintains records of inspections and certifications

Wood Inspectors maintain records of all inspections and certifications that they perform. These records include information such as the date of the inspection, the type of wood product that was inspected, the results of the inspection, and the grade of the wood product.

Interview Tips

Preparing for a Wood Inspector interview can help you make a strong impression and increase your chances of getting the job. Here are a few tips to help you prepare:

1. Research the company and the position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals. You should also learn about the specific duties and responsibilities of the position. This will help you answer questions about your qualifications and experience during the interview.

- Visit the company’s website

- Read articles about the company in the news

- Talk to people who work at the company

2. Practice answering common interview questions

There are a few common interview questions that you are likely to be asked in a Wood Inspector interview. These questions include:

- Tell me about your experience in wood inspection.

- What are the most important qualities of a successful Wood Inspector?

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

You can practice answering these questions by using the STAR method. The STAR method is a storytelling technique that can help you provide clear and concise answers to interview questions.

- Situation: Describe a specific situation or project that you worked on.

- Task: Explain the task that you were responsible for.

- Action: Describe the actions that you took to complete the task.

- Result: Explain the results of your actions.

3. Bring samples of your work

If you have any samples of your work, such as inspection reports or certificates, be sure to bring them to your interview. This will give the interviewer a chance to see your skills and experience firsthand.

4. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire. You should also make sure that your clothes are clean and pressed.

5. Be confident

Confidence is key in any interview. Believe in yourself and your abilities. This will shine through during your interview and make a positive impression on the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wood Inspector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!