Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Woodwork Salvage Inspector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Woodwork Salvage Inspector so you can tailor your answers to impress potential employers.

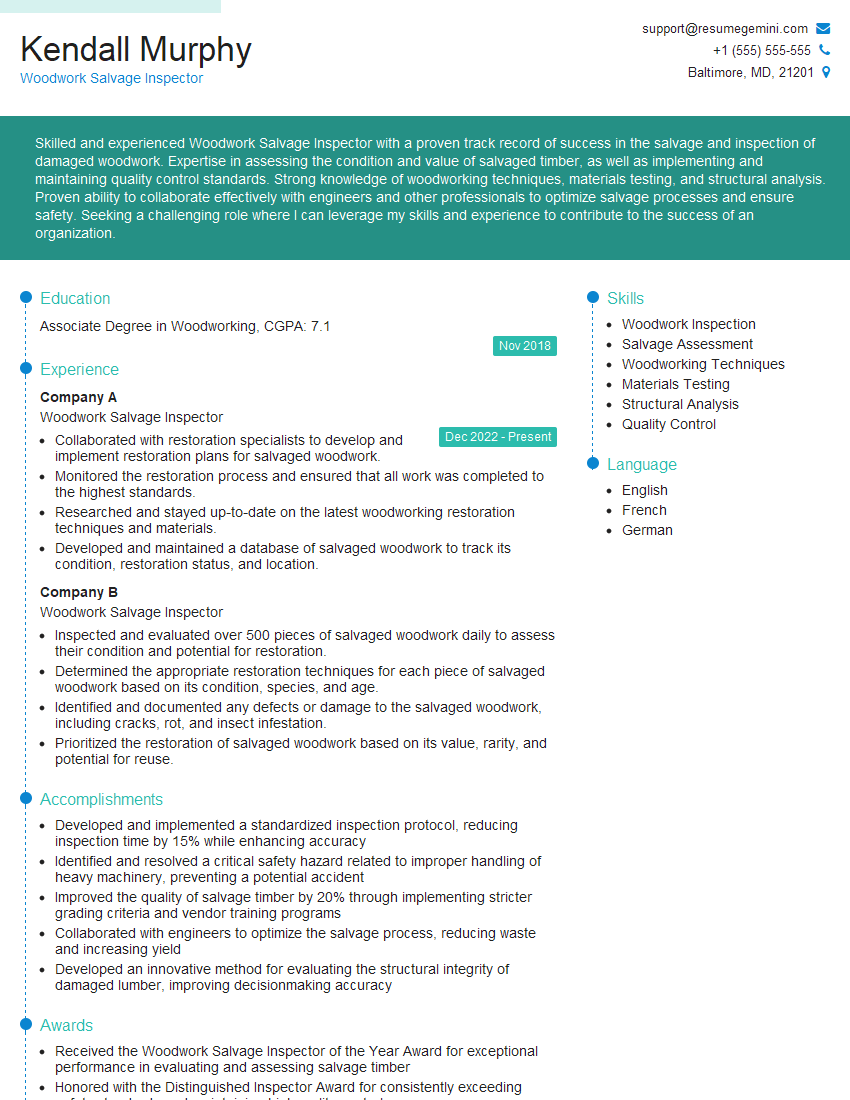

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Woodwork Salvage Inspector

1. How do you determine the grade of a salvaged log?

To determine the grade of a salvaged log, I consider several factors:

- Size and shape: I measure the log’s length, diameter, and taper to assess its suitability for specific purposes.

- Species: I identify the species of wood, as different species have varying properties and values.

- Log defects: I inspect the log for defects such as knots, splits, decay, and insect damage. These defects can reduce the log’s grade and value.

- Clear areas: I measure the volume of clear wood on the log, which indicates its suitability for various products.

- End checks: I examine the ends of the log for cracks or splits, which can affect the log’s structural integrity.

2. Describe your knowledge of wood decay fungi and their impact on salvaged logs.

Wood Decay Fungi

- I am familiar with common wood decay fungi such as brown rot, white rot, and soft rot.

- I understand their different modes of action and the types of damage they cause to wood.

- I can identify signs of fungal decay, such as discoloration, softening, and cracking.

Impact on Salvaged Logs

- I am aware that fungal decay can significantly reduce the value and usability of salvaged logs.

- I can assess the extent of decay and determine whether the log is suitable for salvage or must be discarded.

3. Explain the industry standards for grading salvaged lumber.

The industry standards for grading salvaged lumber vary depending on the organization issuing the standard. Some common standards include:

- National Hardwood Lumber Association (NHLA) Rules for the Inspection of Hardwood Lumber: These rules provide guidelines for grading hardwood lumber based on factors such as species, size, defects, and appearance.

- Softwood Lumber Grading Rules: These rules, developed by various organizations such as the Western Wood Products Association (WWPA) and the Southern Pine Inspection Bureau (SPIB), establish standards for grading softwood lumber based on similar criteria as hardwood lumber.

- American National Standards Institute (ANSI) O2.1: This standard provides a comprehensive set of grading rules for softwood and hardwood lumber, including salvaged lumber.

4. Discuss your experience in using non-destructive testing methods for salvaged wood.

I am familiar with several non-destructive testing methods for salvaged wood, including:

- Stress wave timing: This method involves sending stress waves through the wood and measuring their velocity to assess the wood’s density and stiffness.

- Ultrasonic testing: This method uses high-frequency sound waves to detect internal defects and measure the wood’s thickness.

- Acoustic emission testing: This method monitors acoustic emissions generated by wood under load to identify structural defects and cracks.

- Microwave scanning: This method uses microwaves to detect moisture content and internal defects in wood.

5. How do you communicate your findings and recommendations to clients and stakeholders?

- Written reports: I prepare comprehensive written reports that detail my findings, assessments, and recommendations.

- Verbal presentations: I present my findings and recommendations to clients and stakeholders in clear and concise language, using visual aids to support my points.

- Technical discussions: I engage in technical discussions with clients and stakeholders to explain my findings and address their questions thoroughly.

- Follow-up communication: I maintain regular communication with clients and stakeholders to provide updates and respond to any inquiries.

6. Describe your experience with quality control procedures for salvaged wood products.

- Establishing quality standards: I work with clients to define quality standards for salvaged wood products based on their intended use.

- Inspection and testing: I perform thorough inspections and testing of salvaged wood products to ensure they meet the required quality standards.

- Documentation: I maintain detailed records of all inspections and testing results, including any non-conforming materials.

- Continuous improvement: I participate in continuous improvement initiatives to refine our quality control procedures and ensure the highest quality of salvaged wood products.

7. How do you stay updated on the latest industry trends and best practices for Woodwork Salvage Inspection?

- Industry conferences and seminars: I attend industry conferences and seminars to learn about the latest trends, research, and best practices in woodworking salvage inspection.

- Professional organizations: I am an active member of professional organizations such as the American Wood Protection Association (AWPA) and the Association for Preservation Technology (APT), which provide access to resources and networking opportunities.

- Continuing education courses: I take continuing education courses and workshops to enhance my knowledge and skills, including those related to advancements in non-destructive testing methods and wood preservation techniques.

- Trade publications and research journals: I read trade publications and research journals to stay abreast of the latest developments in the field of woodworking salvage inspection.

8. How do you prioritize your workload and manage multiple projects simultaneously?

I prioritize my workload based on several factors:

- Urgency: I assess the importance and time sensitivity of each project and prioritize urgent projects accordingly.

- Client impact: I consider the potential impact of delays or errors on our clients and prioritize projects that have a significant impact.

- Resource allocation: I assess the availability of resources, such as staff, equipment, and materials, and allocate them efficiently to ensure timely completion of projects.

- Project complexity: I evaluate the complexity of each project and allocate appropriate time and resources to ensure accuracy and thoroughness.

9. Describe your approach to addressing conflicts or disagreements with clients or colleagues.

When faced with conflicts or disagreements, I follow a structured approach:

- Active listening: I actively listen to the other person’s perspective to understand their concerns and motivations.

- Objectivity and empathy: I approach the situation with objectivity and empathy, seeking to understand both the client’s and colleague’s viewpoints.

- Collaborative problem-solving: I engage in collaborative problem-solving by exploring mutually acceptable solutions that address the concerns of all parties.

- Documentation and communication: I document all discussions and agreements clearly to ensure transparency and accountability.

10. What qualities and skills do you possess that make you an effective Woodwork Salvage Inspector?

- Technical expertise: I have a strong understanding of wood properties, defects, and non-destructive testing methods.

- Attention to detail: My attention to detail allows me to identify even minor defects and ensure accuracy in my inspections.

- Communication skills: I effectively communicate my findings, recommendations, and technical information to clients and stakeholders.

- Problem-solving skills: I am adept at identifying and resolving issues related to salvaged wood quality.

- Customer focus: I am committed to providing unparalleled customer service and ensuring client satisfaction.

- Continuous improvement: I am driven to stay updated on industry best practices to enhance the quality of my inspections.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Woodwork Salvage Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Woodwork Salvage Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Woodwork Salvage Inspectors are responsible for ensuring that damaged or salvaged woodwork meets safety and quality standards. Their main duties include:

1. Inspection and Assessment

Inspect damaged or salvaged woodwork to determine its condition, including structural integrity, finish quality, and presence of defects.

- Assess the extent of damage or deterioration and determine whether the woodwork can be salvaged or must be discarded.

2. Salvage and Repair

Salvage damaged woodwork by removing damaged sections, repairing joints, and refinishing surfaces to restore its original condition.

- Repair damaged components or replace them with new ones to ensure the woodwork meets safety and quality standards.

3. Quality Control

Ensure that salvaged and repaired woodwork meets the required specifications and standards.

- Conduct quality control checks and tests to ensure the woodwork is structurally sound and aesthetically pleasing.

4. Documentation

Document the salvage and repair process, including the condition of the woodwork before and after inspection, salvage, and repair.

- Maintain accurate records and generate reports on the findings and recommendations for salvage or discard.

Interview Tips

To ace an interview for a Woodwork Salvage Inspector position, candidates should prepare thoroughly and highlight their relevant skills and experience.

1. Research the Company and Industry

Before the interview, research the company and the woodwork salvage industry. This will help you understand the company’s values, goals, and the specific requirements of the role.

- Visit the company’s website and social media pages to learn about their products, services, and recent projects.

- Read industry publications and articles to stay updated on the latest trends and techniques in woodwork salvage.

2. Highlight Your Woodworking Experience

Emphasize your hands-on experience in woodwork and your ability to assess, repair, and salvage damaged woodwork. Provide specific examples of projects you have worked on and the techniques you used.

- Describe your experience in identifying and repairing structural damage to woodwork, such as cracks, breaks, or rot.

- Explain your knowledge of different types of wood finishes and your ability to refinish and restore damaged surfaces.

3. Demonstrate Your Attention to Detail

Woodwork Salvage Inspectors must have a keen eye for detail and the ability to identify and assess even minor defects in woodwork. Highlight your ability to thoroughly inspect and document the condition of woodwork.

- Provide examples of projects where you successfully identified and resolved subtle damage or deterioration in woodwork.

- Emphasize your ability to create and maintain accurate records and documentation of your findings.

4. Prepare for Technical Questions

Be prepared to answer technical questions about woodwork salvage and repair techniques. These questions may test your knowledge of different types of wood, wood finishes, and salvage methods.

- Review your knowledge of the different types of wood used in construction and their properties.

- Familiarize yourself with the different types of wood finishes and their suitability for different types of woodwork.

Next Step:

Now that you’re armed with the knowledge of Woodwork Salvage Inspector interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Woodwork Salvage Inspector positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini