Are you gearing up for a career in Diamond Polisher? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Diamond Polisher and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

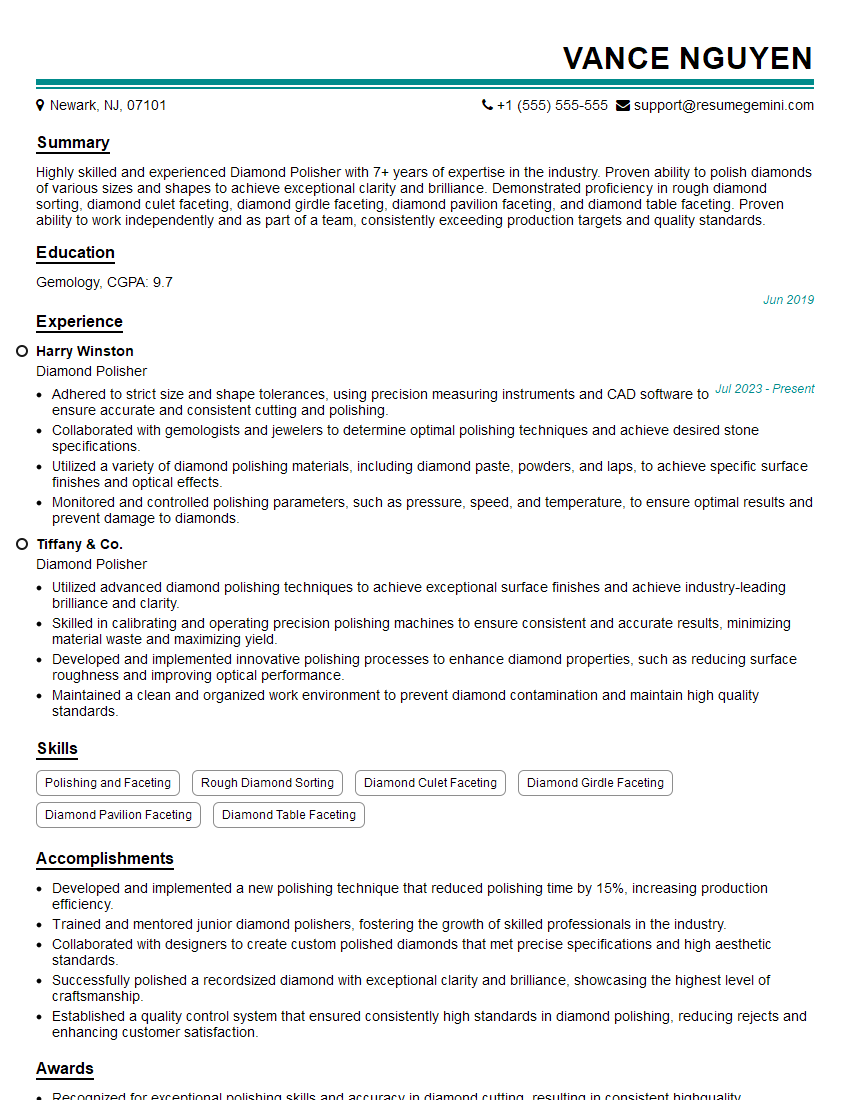

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Diamond Polisher

1. What are the different types of diamond polishing machines and their uses?

There are various types of diamond polishing machines, each designed for specific purposes. Here are some common types:

- Scaife machine: Used for rough grinding and shaping of diamonds with coarse diamond powder.

- Bruting machine: Used for grinding and shaping diamonds into round or oval shapes.

- Blocking machine: Used for further shaping and refining the diamond’s facets.

- Faceting machine: Used for cutting and polishing the diamond’s final facets to achieve a precise shape and brilliance.

- Doping machine: Used for applying a thin layer of diamond powder to the polishing wheel.

2. What are the different types of diamond polishing wheels and their compositions?

Natural Diamond Wheels

- Single-crystal diamond wheels

- Polycrystalline diamond wheels

Synthetic Diamond Wheels

- Monocrystalline diamond wheels

- Polycrystalline diamond wheels

CBN Wheels

- Cubic boron nitride wheels

3. How do you determine the correct diamond grit size for a specific polishing task?

The correct grit size depends on the stage of the polishing process:

- Coarse grits (80-220): Used for rough grinding and shaping.

- Medium grits (325-600): Used for further shaping and refining.

- Fine grits (1000-3000): Used for final polishing and achieving a smooth surface.

4. What are the key factors to consider when choosing a diamond polishing compound?

- Diamond concentration: Higher concentration provides faster cutting but can produce more heat.

- Particle size: Smaller particles produce finer finishes while larger particles remove material more aggressively.

- Binder type: Different binders offer varying levels of adhesion, viscosity, and temperature resistance.

5. How do you maintain optimal temperature during diamond polishing to prevent damage?

- Use water or coolant to lubricate and dissipate heat.

- Maintain a consistent polishing speed to avoid excessive heat buildup.

- Monitor the diamond’s temperature using a pyrometer or laser thermometer.

- Allow the diamond to cool down periodically to prevent cracking.

6. What techniques do you use to achieve a high-quality mirror finish on diamonds?

- Use ultra-fine diamond grit (3000 or higher).

- Apply light pressure during polishing to minimize scratching.

- Use a soft polishing wheel to prevent surface damage.

- Inspect the diamond regularly under magnification to ensure a smooth finish.

7. How do you inspect and evaluate the quality of polished diamonds?

Diamond quality is evaluated based on the 4Cs:

- Carat: Weight in carats.

- Color: Absence of yellow or brown hues.

- Cut: Symmetry, proportions, and brilliance.

- Clarity: Inclusions and blemishes.

Polished diamonds are inspected using a gemological microscope or loupe to assess their quality and identify any imperfections.

8. What safety precautions should be taken while diamond polishing?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a respirator.

- Ensure the polishing equipment is properly maintained and operated.

- Handle diamonds with care to avoid chipping or breaking.

- Store chemicals and diamond powder safely.

- Follow established safety protocols and guidelines.

9. How do you stay updated with the latest diamond polishing techniques and technologies?

- Attend industry conferences and workshops.

- Read trade publications and research papers.

- Engage in online forums and discussions.

- Network with other diamond professionals.

10. How do you handle challenging diamond polishing tasks that require precision and attention to detail?

- Carefully assess the diamond and determine the appropriate polishing strategy.

- Use specialized techniques and equipment to achieve the desired result.

- Take extra precautions to minimize imperfections and maintain diamond integrity.

- Consult with experienced professionals or gemologists for guidance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Diamond Polisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Diamond Polisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Diamond polishers are responsible for cutting and polishing diamonds to create the desired shape, size, and finish. They use a variety of tools and techniques to achieve the desired results, and must have a keen eye for detail and a steady hand.

1. Diamond Cutting

Use diamond saws to cut rough diamonds into the desired shape.

- Determine the appropriate cutting angle and depth for the desired shape.

- Operate diamond saws safely and efficiently.

2. Diamond Polishing

Use diamond polishing wheels and compounds to polish the surface of diamonds.

- Select the appropriate polishing wheel and compound for the desired finish.

- Polish the diamond evenly and consistently.

3. Diamond Inspection

Inspect diamonds for defects and imperfections.

- Use a variety of tools and techniques to identify defects.

- Determine the severity of defects and make recommendations for further treatment.

4. Quality Control

Ensure that diamonds meet the required quality standards.

- Inspect diamonds for compliance with specifications.

- Maintain records of inspection results.

- Identify and correct any quality issues.

Interview Tips

Preparing for a diamond polisher interview can be daunting, but with the right approach, you can increase your chances of success.

1. Research the Company

Take the time to learn about the company you’re applying to. This will help you understand their values, culture, and the specific requirements of the diamond polisher role.

- Visit the company’s website.

- Read industry news and articles.

- Network with people in the industry.

2. Practice Your Skills

Diamond polishing is a skilled trade, so it’s important to practice your skills regularly. This will help you demonstrate your proficiency during the interview.

- Take a diamond polishing course.

- Volunteer at a jewelry store or workshop.

- Practice polishing diamonds at home.

3. Prepare for Common Interview Questions

There are a number of common interview questions that you can expect to be asked, such as:

- Tell me about your experience in diamond polishing.

- What are your strengths and weaknesses as a diamond polisher?

- Why do you want to work for our company?

- What are your salary expectations?

- Do you have any questions for me?

It’s important to prepare for these questions in advance so that you can answer them confidently and concisely.

4. Dress Professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing a suit or other business attire, and making sure that your clothes are clean and pressed.

- Wear a suit or other business attire.

- Make sure your clothes are clean and pressed.

- Arrive on time for your interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Diamond Polisher role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.