Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bead Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

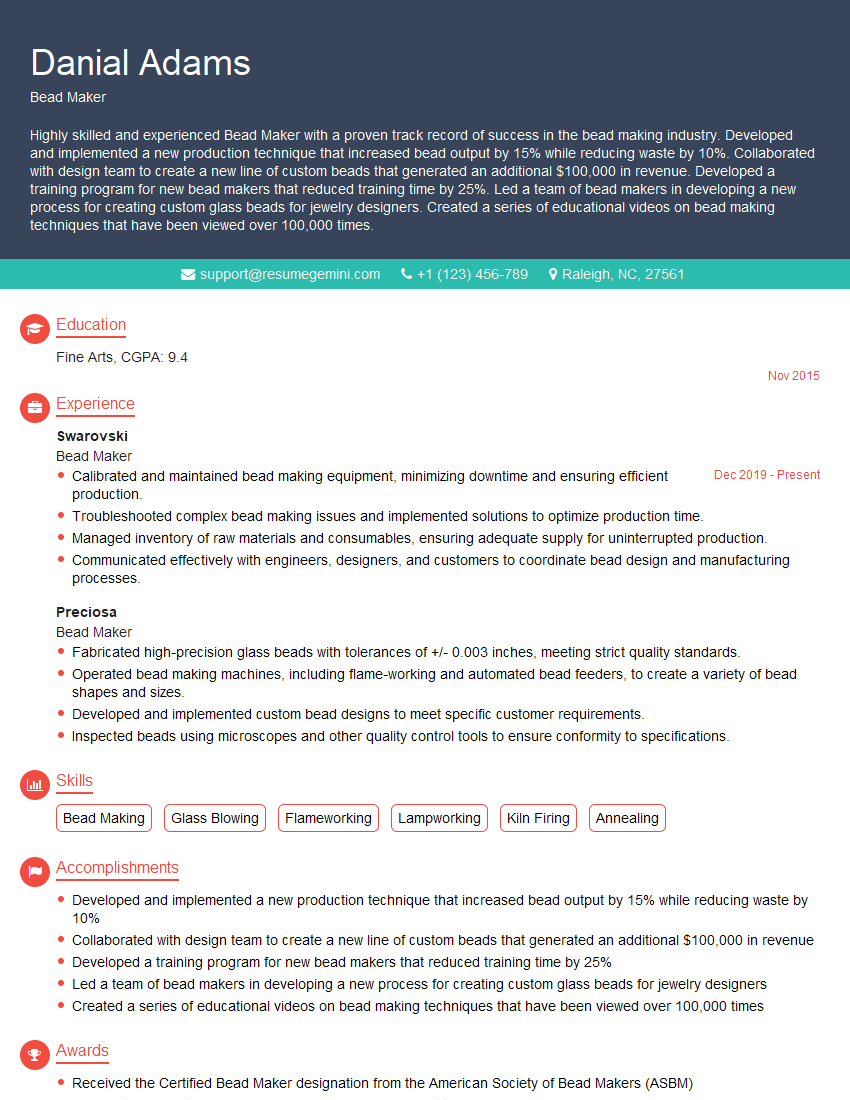

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bead Maker

1. Describe the process of making a bead from start to finish.

The process of making a bead from start to finish involves several steps:

- Gathering materials: This includes selecting the type of glass, colorants, and any other materials needed for the design.

- Preparing the mandrel: The mandrel is a metal rod that the bead will be formed around. It is cleaned and coated with a release agent to prevent the glass from sticking.

- Melting the glass: The glass is heated in a kiln or torch until it melts. The bead maker uses a variety of tools to shape and manipulate the molten glass.

- Forming the bead: Once the glass is molten, the bead maker uses a variety of tools to shape and manipulate the glass. This can involve blowing, shaping with pliers, or using other techniques.

- Annealing the bead: After the bead is formed, it is cooled slowly in a kiln to prevent it from cracking. This process helps to relieve any internal stresses in the glass.

- Finishing the bead: Once the bead is annealed, it can be further finished by grinding, polishing, or adding other decorative elements.

2. What are the different types of beads that can be made?

There are many different types of beads that can be made, including:

- Round beads: These are the most common type of bead and are made by melting glass around a mandrel and then shaping it into a round form.

- Faceted beads: These beads have flat surfaces that have been cut and polished to create a sparkling effect.

- Lampwork beads: These beads are made by melting glass over a flame and then shaping it using a variety of tools.

- Millefiori beads: These beads are made by layering different colors of glass and then cutting them into small pieces. The pieces are then assembled and melted together to create a unique design.

- Dichroic beads: These beads are made by coating glass with a thin layer of metal oxide. This coating creates a shimmering, iridescent effect.

3. What are the different factors that affect the quality of a bead?

The quality of a bead is affected by a number of factors, including:

- The type of glass: The type of glass used will affect the bead’s color, clarity, and durability.

- The melting temperature: The melting temperature of the glass will affect how easily it can be worked and shaped.

- The annealing process: The annealing process will help to relieve any internal stresses in the glass and prevent it from cracking.

- The finishing process: The finishing process will affect the bead’s appearance and durability.

- The skill of the bead maker: The skill of the bead maker will affect the overall quality of the bead.

4. What are the different tools and equipment used in bead making?

The tools and equipment used in bead making include:

- Kiln: A kiln is a heated oven used to melt and anneal glass.

- Torch: A torch is used to melt glass over a flame.

- Mandrel: A mandrel is a metal rod that the bead is formed around.

- Pliers: Pliers are used to shape and manipulate the molten glass.

- Tweezers: Tweezers are used to pick up and place small pieces of glass.

- Grinder: A grinder is used to shape and smooth the finished bead.

- Polisher: A polisher is used to give the bead a shiny finish.

5. What are the safety precautions that must be taken when making beads?

When making beads, it is important to take the following safety precautions:

- Wear safety glasses: Safety glasses will protect your eyes from flying glass particles.

- Wear gloves: Gloves will protect your hands from heat and sharp edges.

- Use a well-ventilated area: A well-ventilated area will help to prevent you from inhaling harmful fumes.

- Keep children and pets away from the work area: Children and pets can be injured by the heat and sharp edges of the tools and equipment.

6. What are the different ways to market and sell beads?

Beads can be marketed and sold in a variety of ways, including:

- Online marketplaces: Online marketplaces such as Etsy and Amazon allow you to sell your beads to a global audience.

- Craft fairs: Craft fairs are a great way to sell your beads to local customers.

- Consignment shops: Consignment shops sell your beads on your behalf and take a commission on each sale.

- Social media: Social media can be used to promote your beads and drive traffic to your website or online store.

7. What are the different trends in bead making?

The trends in bead making are constantly evolving. Some of the current trends include:

- The use of dichroic glass: Dichroic glass creates a shimmering, iridescent effect that is very popular in jewelry making.

- The use of millefiori glass: Millefiori glass is made by layering different colors of glass and then cutting them into small pieces. The pieces are then assembled and melted together to create a unique design.

- The use of beads in jewelry: Beads are becoming increasingly popular for use in jewelry, including necklaces, bracelets, and earrings.

8. What are the challenges of bead making?

Bead making can be a challenging but rewarding craft. Some of the challenges of bead making include:

- The heat: Glass is melted at high temperatures, which can be dangerous if not handled properly.

- The sharp edges: Glass can be sharp, which can lead to cuts and other injuries.

- The fumes: Fumes are released when glass is melted, which can be harmful if inhaled.

- The learning curve: Bead making can be a complex craft to learn, and it takes time and practice to master the techniques.

9. What is your favorite thing about bead making?

My favorite thing about bead making is the creative freedom it allows me. I love being able to experiment with different colors, shapes, and designs to create unique and beautiful pieces of art.

10. What are your goals for your bead making career?

My goals for my bead making career are to continue to learn and grow as an artist. I would like to explore new techniques and designs, and I hope to one day be able to sell my beads to a wider audience.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bead Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bead Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bead Makers are responsible for the production of high-quality beads in a variety of shapes and sizes. Their primary tasks include operating bead-making machines, inspecting finished products, and ensuring that production meets quality standards. Bead Makers also work closely with other members of the production team to ensure that production runs smoothly and efficiently.

1. Machine Operation

Operate bead-making machines to produce beads of various shapes and sizes.

- Set up and calibrate machines according to specifications.

- Monitor machines during operation and make adjustments as needed.

2. Quality Control

Inspect finished products to ensure they meet quality standards.

- Check for defects such as cracks, bubbles, or discoloration.

- Sort and grade beads according to size, shape, and quality.

3. Production Monitoring

Monitor production processes to ensure efficiency and adherence to quality standards.

- Track production output and identify areas for improvement.

- Maintain records of production data and report any issues to supervisors.

4. Team Collaboration

Work closely with other members of the production team.

- Coordinate with machine operators to ensure a smooth flow of production.

- Assist with troubleshooting and problem-solving.

Interview Tips

Preparing for a Bead Maker interview can help you showcase your skills and experience, and increase your chances of success. Here are some tips to help you ace your interview:

1. Research the Company and Position

Before the interview, take some time to research the company and the specific Bead Maker position you are applying for. This will help you understand the company’s culture, mission, and values, as well as the specific requirements of the role. You can find this information on the company’s website, social media pages, and industry publications.

- Example: You might research a company’s website to learn about their history, products, and commitment to sustainability.

2. Practice Answering Common Interview Questions

There are certain interview questions that are commonly asked for Bead Maker positions. By practicing your answers to these questions, you can feel more confident and prepared during the actual interview. Some common questions include:

- Example: “Tell me about your experience in operating bead-making machines.”

- Example: “How do you ensure that the beads you produce meet quality standards?”

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the Bead Maker position. This includes your technical skills, such as your ability to operate bead-making machines, as well as your soft skills, such as your attention to detail and teamwork abilities.

- Example: You might mention a time when you successfully troubleshooted a problem with a bead-making machine.

4. Ask Questions

Asking questions at the end of the interview is a great way to show your interest in the position and the company. It also gives you an opportunity to learn more about the role and the company culture. Some good questions to ask include:

- Example: “What are the biggest challenges facing the Bead Maker team right now?”

- Example: “What are the company’s plans for growth in the future?”

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Bead Maker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Bead Maker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.