Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Orthodontic Band Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

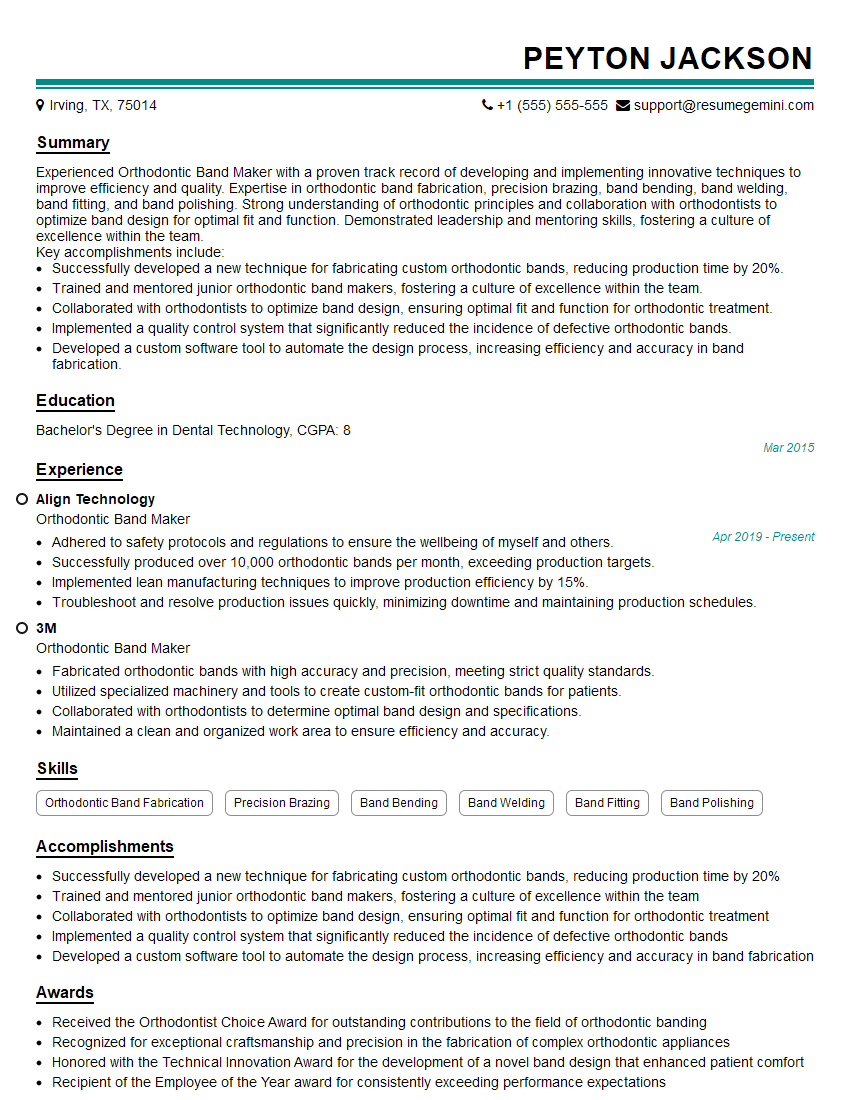

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Orthodontic Band Maker

1. Describe the process of making an orthodontic band from start to finish.

Answer:

- First, I create a wax pattern of the band using a specialized wax that is designed to withstand high temperatures.

- Next, the wax pattern is invested in a gypsum mold and heated to a temperature that melts the wax, leaving a hollow space in the mold.

- Molten metal, typically gold or stainless steel, is then poured into the mold and allowed to cool and solidify.

- Once the metal has solidified, the mold is broken away, and the band is removed.

- The band is then annealed to soften the metal and make it more pliable for shaping and fitting.

- Finally, the band is contoured to fit the patient’s tooth and polished to a smooth finish.

2. What are the different types of orthodontic bands?

Answer:

- Molar Bands: These bands are used to anchor orthodontic appliances to the molars

- Premolar Bands: These bands are similar to molar bands, but they are smaller and are used to anchor appliances to the premolars.

- Sectional Bands:

- These bands are used to anchor appliances to individual sections of teeth.

- They are often used on teeth that are missing or have been damaged.

3. What are the different materials used to make orthodontic bands?

Answer:

- Gold:

- Gold is a noble metal that is resistant to corrosion and tarnishing.

- It is also very strong and durable.

- Stainless steel:

- Stainless steel is a strong and durable material that is also resistant to corrosion.

- It is a more affordable option than gold.

- Titanium:

- Titanium is a lightweight and strong material that is also hypoallergenic.

- It is often used for patients who have allergies to other metals.

4. What are the quality control measures that you use to ensure that orthodontic bands meet the required specifications?

Answer:

- Dimensional accuracy:

- I use precision measuring instruments to ensure that orthodontic bands meet the required dimensions.

- This is important to ensure that the bands fit properly and do not cause any discomfort to the patient.

- Material quality:

- I use only high-quality materials that meet the required specifications.

- I also perform regular quality control checks to ensure that the materials are consistent and free of defects.

- Surface finish:

- I polish orthodontic bands to a smooth finish to reduce the risk of irritation to the patient’s mouth.

- I also inspect the bands for any burrs or sharp edges that could cause discomfort.

5. What are the challenges of making orthodontic bands?

Answer:

- Achieving the required precision: Orthodontic bands must be made to very precise specifications in order to fit properly and function correctly.

- Working with small and delicate materials: Orthodontic bands are often made from thin and delicate materials, which can be difficult to work with.

- Meeting the needs of individual patients: Orthodontic bands must be customized to fit the individual needs of each patient.

6. What is your favorite part of the job?

Answer:

- Helping patients achieve their orthodontic goals: I enjoy seeing the positive impact that orthodontic treatment can have on patients’ lives.

- Creating high-quality products: I take pride in my work and strive to create orthodontic bands that are both functional and beautiful.

- Learning new things: I am always eager to learn new techniques and improve my skills.

7. What are your career goals?

Answer:

- Short-term goals: I am focused on developing my skills and becoming a more experienced orthodontic band maker.

- Long-term goals: I would like to eventually become a manager or supervisor in the orthodontic field.

8. What are your strengths as an orthodontic band maker?

Answer:

- Attention to detail: I am very detail-oriented and take pride in my work.

- Manual dexterity: I have excellent manual dexterity and am able to work with small and delicate materials.

- Problem-solving skills: I am able to quickly identify and solve problems that may arise during the production process.

9. What are your weaknesses as an orthodontic band maker?

Answer:

- Experience: I am relatively new to the field of orthodontic band making and am still learning some of the more advanced techniques.

- Speed: I am not yet the fastest band maker, but I am confident that I can improve my speed with practice.

10. Why are you interested in working for this company?

Answer:

- Reputation: I am impressed by your company’s reputation for producing high-quality orthodontic products.

- Culture: I believe that my values align with your company’s culture of teamwork, innovation, and customer service.

- Growth opportunities: I am excited about the potential for growth and development within your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Orthodontic Band Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Orthodontic Band Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Orthodontic Band Maker plays a critical role in the fabrication of orthodontic appliances. The key job responsibilities include:1. Band Forming

Utilizing specialized tools and materials, form and contour orthodontic bands to precise specifications.

- Properly prepare teeth and take accurate impressions.

- Select and adjust bands to fit the patient’s teeth.

2. Welding and Soldering

Weld and solder bands to ensure proper fit and stability.

- Use specialized welding and soldering equipment.

- Follow safety protocols and maintain a clean work area.

3. Polishing and Finishing

Polish and finish bands to achieve a smooth surface and optimal aesthetics.

- Remove excess materials and sharp edges.

- Apply appropriate coatings or materials for corrosion resistance.

4. Quality Control

Inspect and verify the quality of orthodontic bands.

- Ensure bands meet specifications and industry standards.

- Identify and correct any defects or imperfections.

Interview Tips

To ace an interview for an Orthodontic Band Maker position, follow these tips:1. Research the Company and Industry

Gather information about the orthodontic company, its products, and the industry as a whole. This knowledge demonstrates your interest and enthusiasm.

- Visit the company website and social media pages.

- Read articles and research reports related to orthodontics.

2. Highlight Your Technical Skills

Emphasize your proficiency in band forming, welding, soldering, and polishing techniques. Provide examples of your work and any relevant certifications.

- Quantify your experience, such as the number of bands fabricated daily.

- Describe specific cases where you demonstrated your precision and attention to detail.

3. Showcase Your Quality Control Approach

Explain your understanding of quality control procedures and your commitment to producing high-quality orthodontic appliances.

- Describe your experience with inspection techniques and defect identification.

- Share examples of how you implemented quality improvements in your work.

4. Prepare for Behavioral Questions

Be prepared to answer questions that assess your teamwork, communication skills, and problem-solving abilities.

- Use the STAR method (Situation, Task, Action, Result) to provide clear and concise answers.

- Practice describing your contributions to a team project or how you handled a challenging situation.

5. Dress Professionally and Be Punctual

First impressions matter, so dress appropriately for the interview. Arrive on time to show your respect for the company and the interviewer.

- Choose a business casual or formal attire that is clean and well-pressed.

- Allow extra time for travel and unexpected delays.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Orthodontic Band Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!