Feeling lost in a sea of interview questions? Landed that dream interview for Medical Appliance Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Medical Appliance Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

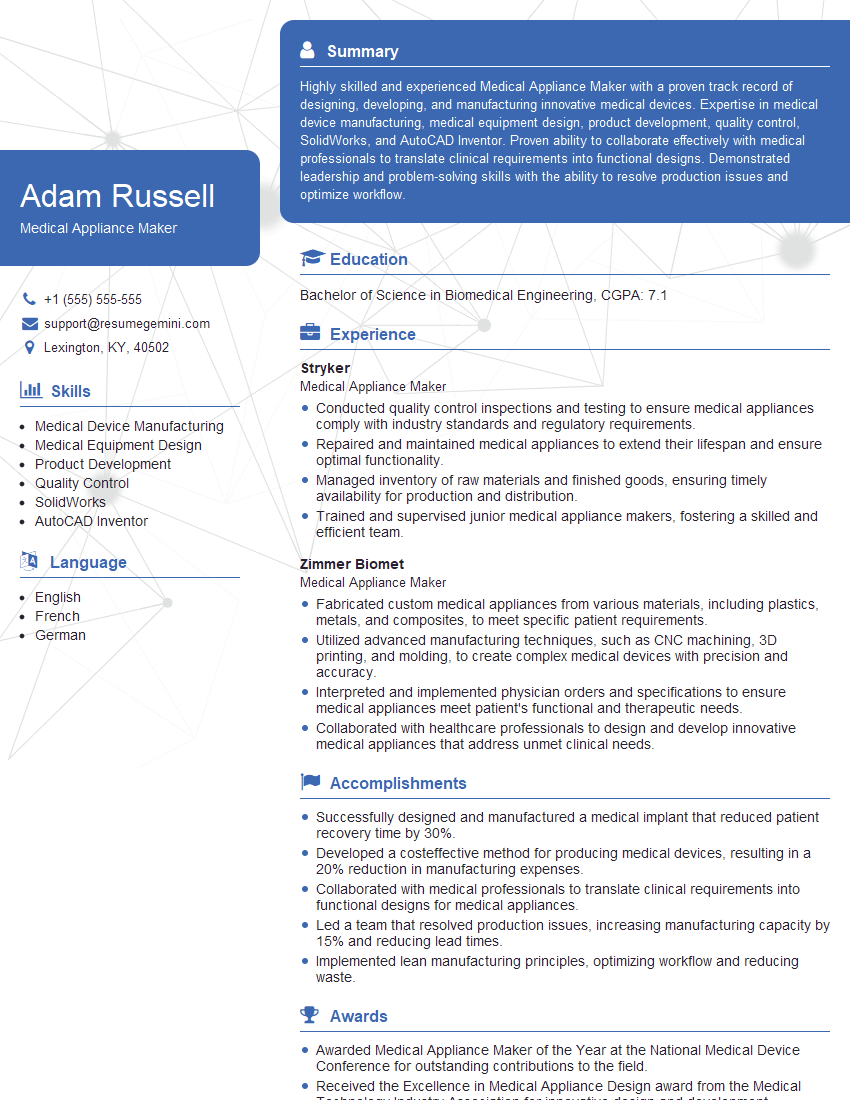

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Medical Appliance Maker

1. How do you ensure the precision and accuracy of medical appliances during the manufacturing process?

To ensure precision and accuracy during the manufacturing process, I employ the following measures:

- Adhering to ISO Standards: I strictly follow established ISO standards and quality management systems throughout the production process.

- Calibration and Maintenance: I regularly calibrate and maintain all equipment used in manufacturing to ensure their accuracy and precision.

- Quality Control Inspections: I conduct thorough quality control inspections at multiple stages of the process, using specialized measuring tools and techniques.

- Statistical Process Control: I implement statistical process control methods to monitor and analyze production data, identifying areas for improvement and maintaining consistency.

2. Describe your experience in using Computer-Aided Design (CAD) software for medical appliance design.

CAD Proficiency

- Thorough knowledge of industry-leading CAD software such as SolidWorks, AutoCAD, and CATIA.

- Proficient in creating precise 3D models, detailed drawings, and technical documentation.

- Experience in designing medical appliances with complex shapes, assemblies, and ergonomic considerations.

Design Optimization

- Utilized CAD tools for finite element analysis (FEA) to optimize designs for strength, durability, and functionality.

- Incorporated design for manufacturing (DFM) principles to ensure manufacturability and cost-effectiveness.

3. How do you stay up-to-date with the latest advancements in medical appliance technology and materials?

To stay abreast of industry advancements, I actively engage in the following practices:

- Industry Conferences and Webinars: I attend industry conferences and webinars to learn about new technologies, materials, and best practices.

- Technical Publications and Journals: I subscribe to and regularly read technical publications and journals to stay informed about the latest research and developments.

- Networking and Collaboration: I connect with medical professionals, engineers, and industry experts to share knowledge and discuss emerging trends.

- Continuing Education: I participate in continuing education programs and workshops to enhance my skills and stay current with industry standards.

4. Provide an example of a challenging medical appliance manufacturing project you’ve worked on and how you overcame the obstacles.

In my previous role, I led the manufacturing of a complex surgical instrument for a major medical device company. The instrument required high precision, intricate assembly, and the use of specialized materials.

- Problem: Calibrating the instrument to meet the required accuracy specifications proved difficult due to the sensitive nature of the materials.

- Solution: I collaborated with a team of engineers and metrologists to develop a custom calibration procedure using advanced measuring equipment and techniques, ensuring the instrument met the necessary tolerances.

- Outcome: The surgical instrument was successfully manufactured, passed all quality control tests, and received regulatory approval for market use.

5. Describe your experience in troubleshooting and repairing medical appliances.

- Diagnostics: I have developed a systematic approach to diagnosing and identifying faults in medical appliances.

- Troubleshooting: I possess strong troubleshooting skills and utilize diagnostic tools to pinpoint the root cause of malfunctions.

- Repairs: I am proficient in performing repairs on various types of medical appliances, ensuring they meet original specifications and safety standards.

- Documentation: I maintain detailed documentation of all repairs and troubleshooting procedures for future reference and quality assurance.

6. How do you ensure the safety and effectiveness of medical appliances during production and after deployment in healthcare settings?

- Safety Compliance: I am well-versed in industry safety standards such as IEC 60601 and ensure that all appliances adhere to these regulations.

- Hazard Analysis: I conduct thorough hazard analyses to identify potential risks and implement appropriate safeguards.

- Testing and Validation: I participate in rigorous testing and validation processes to verify the performance and safety of medical appliances.

- Post-Market Surveillance: I monitor and track feedback on deployed appliances to identify any potential issues and take corrective actions as needed.

7. Describe your experience in working with medical professionals and healthcare organizations.

- Collaboration: I have successfully collaborated with medical professionals and healthcare organizations to understand their needs and provide customized solutions.

- Training and Support: I have provided training and support to healthcare staff on the proper use and maintenance of medical appliances.

- Feedback and Innovation: I actively seek feedback from healthcare professionals to identify areas for improvement and drive innovation in appliance design and functionality.

8. How do you handle the ethical responsibilities associated with manufacturing medical appliances that impact patient safety?

- Patient-Centered Approach: I prioritize patient safety above all and ensure that every appliance is manufactured with the highest ethical standards.

- Compliance and Regulations: I adhere strictly to industry regulations and ethical guidelines to ensure the integrity and effectiveness of medical appliances.

- Transparency and Accountability: I maintain open communication with stakeholders and am accountable for the quality and safety of my work.

9. Describe your experience in managing a team of medical appliance makers.

- Collaboration and Leadership: I am an effective team leader who fosters collaboration and empowers team members to contribute their expertise.

- Delegation and Accountability: I delegate tasks appropriately and hold team members accountable for their responsibilities.

- Performance Management: I provide regular feedback, coaching, and training to support team members’ professional development.

10. How do you stay organized and manage multiple projects simultaneously while ensuring deadlines are met?

- Prioritization and Planning: I prioritize tasks based on importance and urgency and develop a comprehensive plan to manage multiple projects effectively.

- Time Management Tools: I utilize time management tools such as Gantt charts and project management software to track progress and stay organized.

- Communication and Coordination: I maintain regular communication with stakeholders to ensure timely updates and address any potential issues.

- Delegation and Collaboration: When necessary, I delegate tasks and collaborate with team members to share the workload and meet deadlines.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Medical Appliance Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Medical Appliance Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Medical Appliance Makers, also known as Orthopedic Appliance Technicians or Prosthetists, hold vital responsibilities in the healthcare sector by designing, fabricating, and fitting medical appliances to aid individuals with disabilities, injuries, or deformities.

1. Assessment and Measurement

These professionals conduct thorough assessments and take precise measurements of patients to determine the specific requirements for each appliance.

- Evaluate patients’ medical history, physical condition, and functional needs

- Obtain accurate measurements and impressions to create customized designs

2. Appliance Design and Fabrication

Based on the assessment results, Medical Appliance Makers design, create, and assemble medical appliances using various materials and techniques.

- Utilize computer-aided design (CAD) software and traditional tools to design appliances

- Fabricate appliances using materials such as plastics, metals, and fabrics

3. Fitting and Modifications

They ensure proper fit and functionality of appliances by performing fittings and making necessary modifications or adjustments.

- Fit appliances to patients and assess their comfort and mobility

- Make modifications to appliances to improve fit and functionality

4. Education and Support

Medical Appliance Makers provide instructions and support to patients on how to use and care for their appliances.

- Educate patients on the proper use and maintenance of appliances

- Monitor patients’ progress and provide ongoing support

Interview Tips

To ace the interview for a Medical Appliance Maker position, candidates should prepare thoroughly by researching the role, practicing their answers, and demonstrating their skills. Here are some tips:

1. Research the Company and Industry

Familiarize yourself with the company’s mission, values, and products to demonstrate your interest and understanding of their business.

- Visit the company’s website and social media pages

- Read industry publications and news articles

2. Highlight Your Technical Skills

Emphasize your knowledge of materials, fabrication techniques, and design principles relevant to medical appliance making.

- Discuss your experience with CAD software, fabrication equipment, and materials

- Showcase your ability to create precise and functional appliances

3. Demonstrate Your Patient Care Skills

Convey your understanding of patient needs and your ability to provide compassionate care.

- Highlight your interpersonal skills and ability to communicate effectively with patients

- Share examples of how you have addressed patient concerns or provided support

4. Practice Your Answers

Prepare answers to common interview questions and practice delivering them clearly and concisely.

- Rehearse your responses to questions about your experience, skills, and qualifications

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers

5. Ask Thoughtful Questions

Asking informed questions during the interview shows your engagement and interest in the position.

- Inquire about the company’s approach to patient care and innovation

- Ask about opportunities for professional development and growth within the organization

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Medical Appliance Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.