Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Contact Lens Cutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

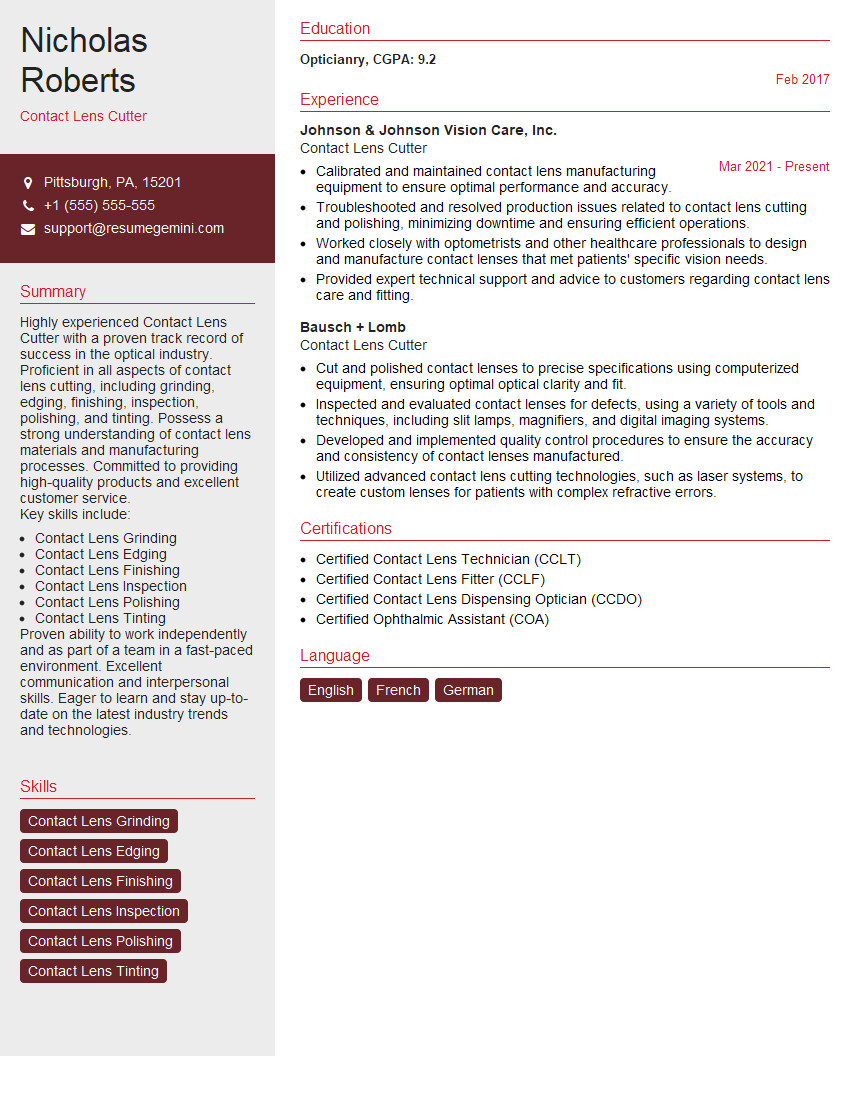

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Contact Lens Cutter

1. What is the difference between a lathe and a CNC machine?

A lathe is a machine tool that spins a piece of material while a cutting tool is used to shape it, while a CNC machine is a computer-controlled machine that uses a series of coded instructions to move a cutting tool and shape a piece of material

- Lathes are typically used for simple operations, such as turning, facing, and boring, while CNC machines can perform more complex operations, such as milling, drilling, and tapping.

- Lathes are typically less expensive and easier to operate than CNC machines.

2. What are the different types of contact lenses?

Types of Contact Lenses

- Soft Contact Lenses

- Hard Contact Lenses

- Gas Permeable Contact Lenses

Advantages of Different Types

- Soft Contact Lenses: Comfortable to wear, easy to insert and remove, and can correct a wide range of vision problems.

- Hard Contact Lenses: Durable, can correct astigmatism, and provide clear vision.

- Gas Permeable Contact Lenses: Combination of soft and hard contact lenses, offering comfort and durability.

3. What are the safety precautions that must be taken when working with contact lenses?

When dealing with contact lenses, it is essential to follow safety precautions to prevent any harm or discomfort to the eyes. Here are some critical safety measures to consider:

- Wash your hands thoroughly with soap and water before handling contact lenses.

- Clean and disinfect contact lenses regularly as per the instructions provided by your eye care professional.

- Never wear contact lenses longer than the recommended duration.

- Avoid sleeping with contact lenses unless specifically prescribed by your eye care professional.

- Store contact lenses in a clean and sterile solution when not in use.

- Never share contact lenses with others.

- If you experience any discomfort or irritation while wearing contact lenses, remove them immediately and consult your eye care professional.

4. What are the different types of equipment used in the production of contact lenses?

The production of contact lenses involves the use of specialized equipment to ensure precision, quality, and safety. Here are some common types of equipment utilized in the manufacturing process:

- Lathes: Used for shaping and cutting the contact lens material to create the desired curvature and thickness.

- CNC Machines: Computer-controlled machines that perform precise cutting and engraving operations on the contact lens surface.

- Molding Machines: Used to shape and form the contact lens material into the desired shape and size.

- Polishing Machines: Employed to smooth and polish the contact lens surface, ensuring a comfortable fit on the eye.

- Inspection Equipment: Used to examine the quality and accuracy of the contact lenses, ensuring they meet the required standards.

5. What are the quality control procedures that must be followed in the production of contact lenses?

Maintaining stringent quality control procedures is critical in the production of contact lenses to ensure the safety and effectiveness of the final product. Here are some essential quality control measures:

- Raw Material Inspection: Inspecting raw materials to verify their quality and compliance with predetermined standards.

- In-Process Inspection: Regularly monitoring the production process to ensure that each step meets the required specifications.

- Final Product Inspection: Thoroughly examining finished contact lenses for any defects or imperfections before packaging and distribution.

- Documentation and Traceability: Maintaining detailed records of all production processes and quality control checks for traceability and accountability.

- Compliance with Industry Standards: Adhering to established industry standards and regulations to guarantee the safety and efficacy of the contact lenses.

6. What are the different types of contact lens materials?

Types of Contact Lens Materials

- Polymethyl Methacrylate (PMMA)

- Silicone Hydrogel

- Fluor silicone acrylate

Properties of Different Materials

- PMMA: Hard and durable, but less permeable to oxygen.

- Silicone Hydrogel: Soft and comfortable, with high oxygen permeability.

- Fluor silicone acrylate: Combination of PMMA and silicone hydrogel, offering high oxygen permeability and durability.

7. What are the different factors that affect the fit of a contact lens?

Factors Affecting Contact Lens Fit

- Corneal Curvature

- Corneal Diameter

- Tear Film Thickness

- Lid Anatomy

- Eye Movements

8. How do you troubleshoot common contact lens problems?

Troubleshooting Common Contact Lens Problems

- Discomfort or irritation: Check for foreign objects, ensure proper fit, and consult an eye care professional.

- Blurry vision: Ensure lenses are clean and inserted correctly, consult an eye care professional if vision persists.

- Tearing or redness: Remove lenses and consult an eye care professional promptly.

- Lens dislodgement: Check fit and ensure lenses are not too loose.

- Lens damage: Remove lenses and consult an eye care professional for replacement.

9. What are the latest advancements in contact lens technology?

Advancements in Contact Lens Technology

- Smart Contact Lenses

- Extended Wear Contact Lenses

- Multifocal Contact Lenses

- Orthokeratology

10. What are the career opportunities for contact lens cutters?

Individuals skilled in contact lens cutting have various career opportunities within the ophthalmic industry. They can work in:

- Contact Lens Manufacturing Companies

- Optical Laboratories

- Eye Care Clinics and Hospitals

- Research and Development

- Sales and Customer Service

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Contact Lens Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Contact Lens Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Contact Lens Cutter is responsible for cutting contact lenses to the prescribed specifications of eye care professionals. The role requires precision, attention to detail, and a thorough understanding of contact lens manufacturing processes. Key responsibilities of a Contact Lens Cutter include:

1. Lens Cutting

Using specialized equipment, precisely cut contact lenses according to provided prescriptions. Ensure lenses meet specifications for diameter, thickness, base curve, and power.

2. Lens Inspection

Carefully inspect cut lenses for any imperfections, such as scratches, bubbles, or irregularities. Verify lens quality using magnification tools and ensure compliance with standards.

3. Lens Finishing

Perform finishing processes on cut lenses, including polishing, edging, and tinting as required. Ensure lenses are smooth, comfortable, and meet aesthetic expectations.

4. Machine Maintenance

Maintain and calibrate lens cutting equipment regularly. Troubleshoot and repair minor issues to ensure optimal performance and accuracy.

5. Quality Control

Implement quality control measures to ensure the production of high-quality contact lenses. Conduct regular checks and monitor processes to identify and address any deviations from standards.

Interview Tips

To ace an interview for a Contact Lens Cutter position, candidates should prepare thoroughly and highlight their relevant skills and experience. Here are some tips and hacks to help:

1. Research the Company and Role

Research the company’s history, products, and reputation. Understand the specific role and its requirements. This knowledge will demonstrate your interest and preparedness.

2. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and motivation. Practice answering them clearly and concisely, using specific examples to support your claims.

3. Brush Up on Technical Knowledge

Review the principles of contact lens manufacturing, including lens design, cutting techniques, and quality control. This will enhance your credibility and show your grasp of the technical aspects of the job.

4. Highlight Precision and Attention to Detail

Emphasize your meticulous nature and ability to handle precise tasks. Describe situations where you have successfully worked with small or intricate components and maintained high levels of accuracy.

5. Showcase Quality-Oriented Mindset

Demonstrate your commitment to quality by discussing your experience with quality control procedures. Explain how you have ensured the production of high-quality products and maintained compliance with standards.

6. Prepare Questions for the Interviewers

Prepare thoughtful questions to ask the interviewers about the role, the company’s culture, and any potential career growth opportunities. This shows your engagement and interest in learning more about the position.

Next Step:

Now that you’re armed with the knowledge of Contact Lens Cutter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Contact Lens Cutter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini