Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Boring and Filling Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

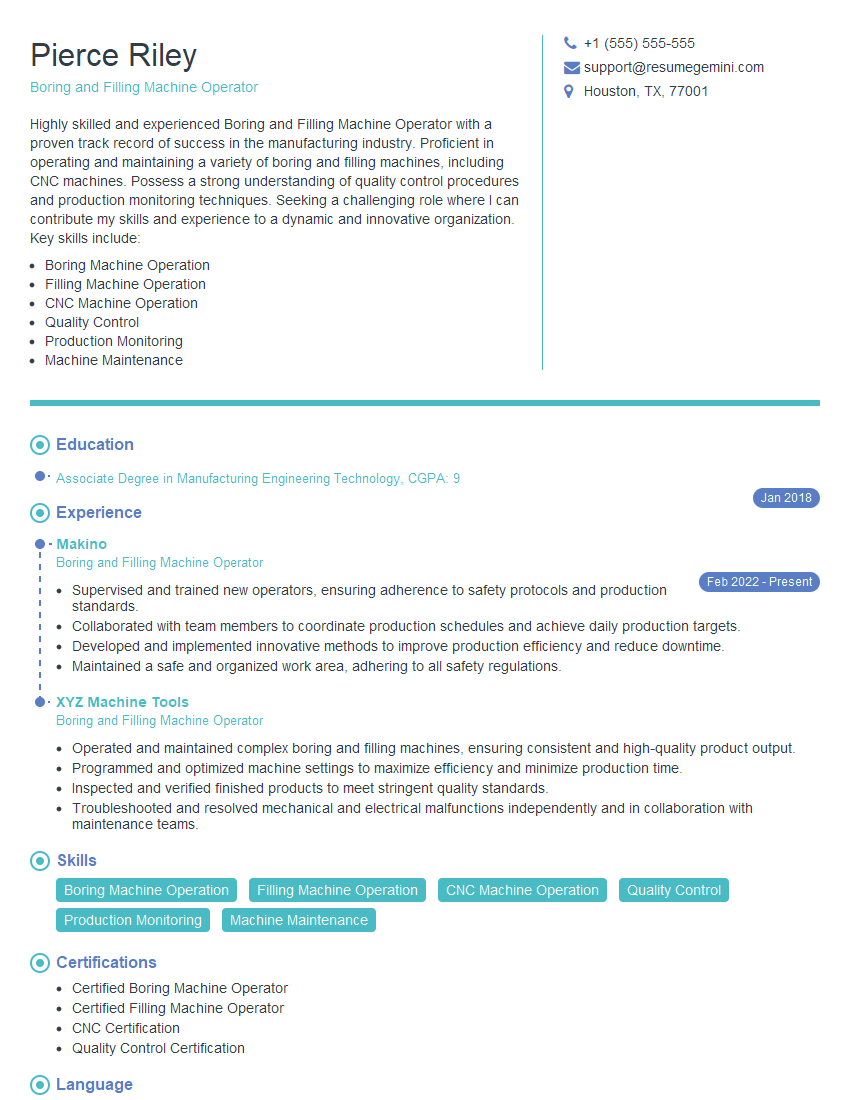

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Boring and Filling Machine Operator

1. What are the key responsibilities of a Boring and Filling Machine Operator?

- Operate and maintain boring and filling machines

- Set up and adjust machines to produce high-quality products

- Monitor machines and make adjustments as needed

- Inspect products and ensure they meet specifications

- Keep work area clean and organized

2. What are the different types of boring and filling machines?

Types of Boring Machines

- Horizontal boring machines

- Vertical boring machines

- Radial boring machines

- Jig boring machines

- CNC boring machines

Types of Filling Machines

- Volumetric filling machines

- Gravimetric filling machines

- In-line filling machines

- Rotary filling machines

- Inline filling machines

3. What are the safety precautions that must be followed when operating boring and filling machines?

- Wear appropriate safety gear

- Inspect machines before each use

- Keep hands and body away from moving parts

- Never leave machines unattended while they are running

- Follow all safety procedures as outlined by the manufacturer

4. What are the common problems that can occur with boring and filling machines and how do you troubleshoot them?

- Problem: Machine is not producing high-quality products

Troubleshooting: Check the machine settings and make sure they are correct. Inspect the tools and make sure they are sharp. Check the material and make sure it is of good quality. - Problem: Machine is not running smoothly

Troubleshooting: Check the machine for any loose parts or obstructions. Lubricate the machine according to the manufacturer’s instructions. Check the power supply and make sure it is adequate. - Problem: Machine is making excessive noise

Troubleshooting: Check the machine for any loose parts or obstructions. Lubricate the machine according to the manufacturer’s instructions. Check the bearings and make sure they are in good condition.

5. What are the maintenance procedures that must be followed to keep boring and filling machines in good working order?

- Clean machines regularly

- Lubricate machines according to the manufacturer’s instructions

- Inspect machines for wear and tear

- Replace worn parts as needed

- Follow all maintenance procedures as outlined by the manufacturer

6. What are the quality control procedures that must be followed to ensure that products produced by boring and filling machines meet specifications?

- Inspect products regularly

- Use measuring tools to ensure that products meet specifications

- Keep records of all inspections

- Take corrective action if products do not meet specifications

- Follow all quality control procedures as outlined by the manufacturer

7. What are the different types of materials that can be bored and filled?

- Metals

- Plastics

- Wood

- Glass

- Ceramics

8. What are the different types of fillings that can be used?

- Liquids

- Powders

- Gases

- Pastes

- Solids

9. What are the different industries that use boring and filling machines?

- Automotive

- Aerospace

- Medical

- Pharmaceutical

- Food and beverage

10. What are the latest trends in boring and filling machine technology?

- Increased use of automation

- Development of new materials

- Improved quality control procedures

- Increased focus on sustainability

- Development of new applications

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Boring and Filling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Boring and Filling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Boring and Filling Machine Operator is responsible for operating and maintaining machines that bore and fill holes in various materials. The operator must have a strong understanding of the machines and their operation, as well as the materials being processed. The operator must also be able to troubleshoot and resolve any problems that may occur with the machines.

1. Set up and operate boring and filling machines

The operator must be able to set up and operate the machines according to the specifications of the job. This includes setting the proper speed, feed, and depth of cut for the machine. The operator must also be able to load and unload the materials being processed.

- Set up and adjust boring machines to bore holes in various materials and ensure accurate dimensions.

- Fill bore holes with appropriate materials using filling machines, ensuring proper filling and sealing.

2. Monitor machine operation and make adjustments

The operator must be able to monitor the operation of the machines and make adjustments as needed. This includes monitoring the temperature, pressure, and flow of the materials being processed. The operator must also be able to identify any problems with the machines and take corrective action.

- Monitor the operation of boring and filling machines, adjusting parameters as necessary to ensure smooth operation.

- Troubleshoot and resolve any issues that arise during machine operation, minimizing downtime and maintaining productivity.

3. Clean and maintain machines

The operator must be able to clean and maintain the machines according to the manufacturer’s specifications. This includes lubricating the machines, cleaning the cutting tools, and checking the alignment of the machines. The operator must also be able to perform minor repairs on the machines.

- Clean and lubricate boring and filling machines as per manufacturer’s specifications, maintaining their optimal performance.

- Inspect and maintain cutting tools to ensure precision and efficiency during operation, reducing downtime and ensuring product quality.

4. Follow safety regulations

The operator must be able to follow all safety regulations when operating and maintaining the machines. This includes wearing proper safety gear, following lockout/tagout procedures, and adhering to all company safety policies.

- Adhere to all applicable safety regulations and guidelines, ensuring a safe work environment and minimizing potential hazards.

- Wear appropriate personal protective equipment (PPE) to prevent injuries while operating machinery.

Interview Tips

To prepare for an interview for a Boring and Filling Machine Operator position, you should follow these tips:

1. Research the company and the position

Before you go to the interview, you should research the company and the position. This will help you to understand the company’s culture and the specific requirements of the job. You can research the company’s website, Glassdoor, and other online resources.

- Visit the company’s website to gather information about their products, services, and culture.

- Read online reviews and testimonials from current and former employees to gain insights into the company’s work environment and management style.

2. Practice your answers to common interview questions

There are a number of common interview questions that you should be prepared to answer. These questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with boring and filling machines?

- How do you handle working in a fast-paced environment?

- What are your salary expectations?

3. Dress professionally

You should dress professionally for your interview. This means wearing a suit or business casual attire. You should also make sure that your clothes are clean and pressed.

- Choose formal or business casual attire that is clean, pressed, and appropriate for an office environment.

- Consider the company’s dress code and adjust your outfit accordingly.

4. Be on time

Punctuality is important for any job interview. You should arrive at the interview on time or even a few minutes early. This shows that you are respectful of the interviewer’s time.

- Plan your route in advance and allow ample time for travel, accounting for potential traffic or delays.

- Arrive at the interview location a few minutes early to show your punctuality and respect for the interviewer’s time.

5. Be confident and enthusiastic

Be confident and enthusiastic during your interview. This will show the interviewer that you are interested in the position and that you are confident in your abilities. You should also be prepared to talk about your experience and qualifications.

- Maintain a positive and enthusiastic attitude throughout the interview, demonstrating your interest in the position and the company.

- Speak clearly and confidently, articulating your thoughts and experiences effectively.

6. Ask questions

At the end of the interview, you should ask the interviewer some questions. This shows that you are interested in the position and that you are taking the interview seriously. You can ask about the company, the position, or the interviewer’s experience.

- Prepare thoughtful questions to ask the interviewer, demonstrating your engagement and interest in the position and the company.

- Inquire about the company’s growth plans, industry trends, and opportunities for professional development.

7. Follow up

After the interview, you should send a thank-you note to the interviewer. This shows that you are appreciative of the interviewer’s time and that you are still interested in the position.

- Send a personalized thank-you email within 24 hours of the interview, expressing your gratitude for the opportunity.

- Reiterate your interest in the position and highlight any specific aspects of the interview that impressed you.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Boring and Filling Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Boring and Filling Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.